Full automatic speed reducing clutch and the washing machine therewith and washing method

A deceleration clutch, fully automatic technology, applied in the field of washing machines, can solve the problems of low washing ratio, easy entanglement of clothes, weak strength, etc., and achieve the effects of strong bearing capacity, high transmission efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

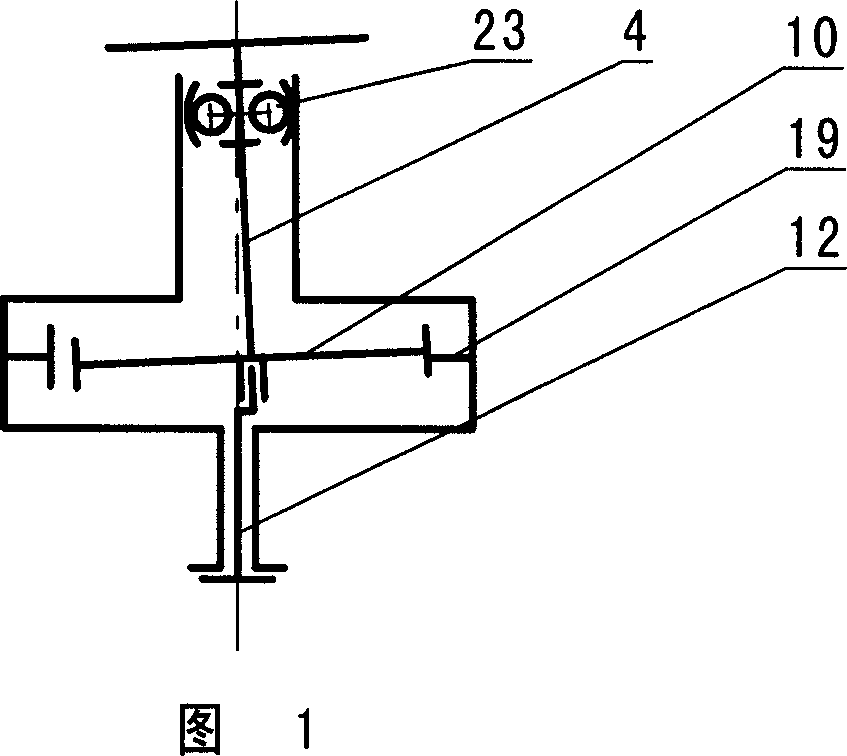

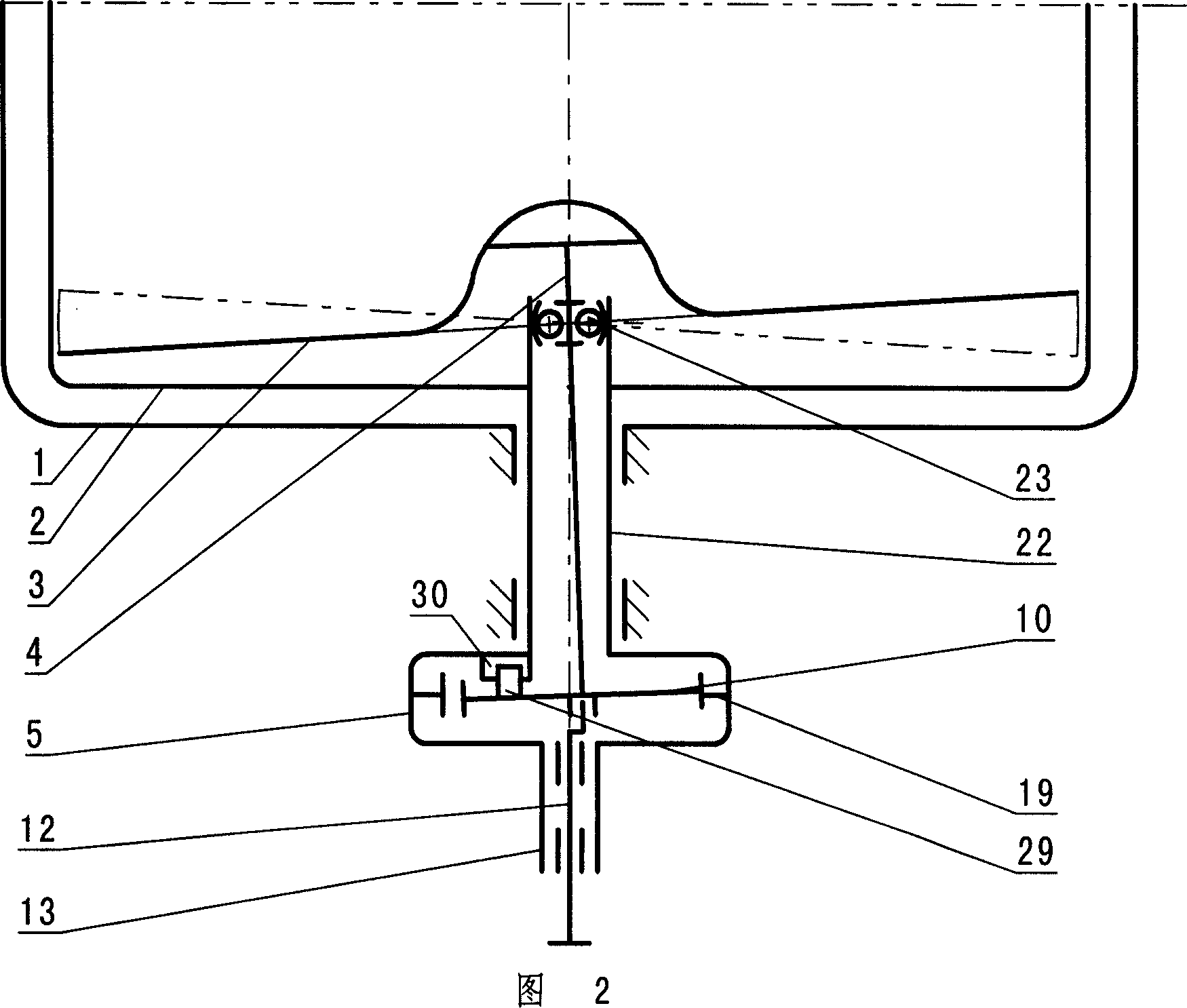

[0051] 1. Combining with Figure 2, the deceleration mechanism is a single set of pendulum shaft gear mechanism, which is a planetary gear transmission with variable tooth thickness and small tooth difference. The input shaft 12 is composed of the input shaft 12; the central inner gear 19 is connected with the upper shaft sleeve 22, the planetary gear 10 is connected with the balance shaft 4, and the inner and outer gears are in epicyclic meshing; the planetary gear 10 is provided with a clutch pawl 29, and the brake wheel 5 is built with a Clutch bump 30.

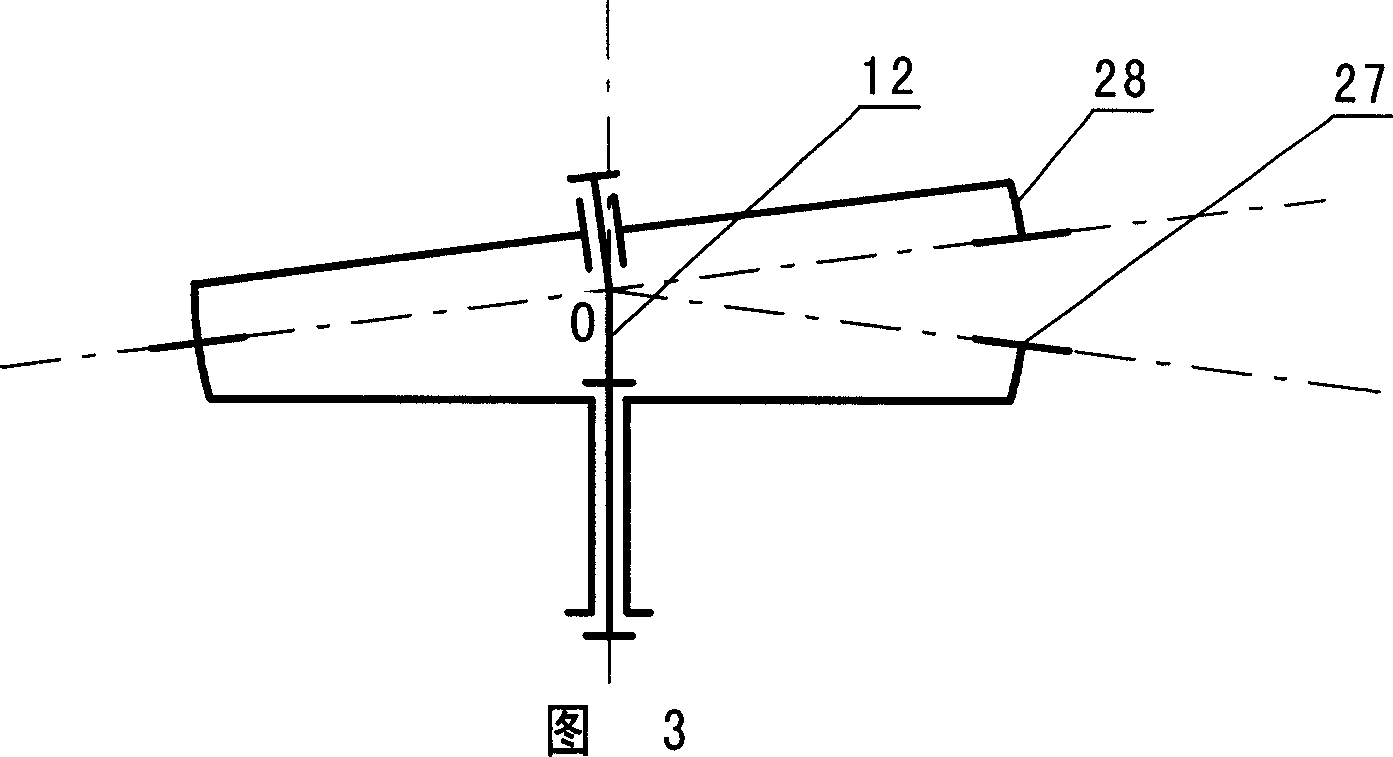

[0052] 2. Combined with Figure 4, the reduction mechanism is a single set of pendulum bevel gear mechanism, which is a conical planetary gear transmission with few teeth differences. It is located between the wave wheel 3 and the inner barrel 2. The input shaft 12 of the shaft head arm is composed of; the central bevel gear 27 is connected with the inner barrel 2, the planetary gear 28 is connected with the pulsator 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com