Composite shear wall and construction method

A technology of shear walls and steel bars, applied in the direction of walls, structural elements, building components, etc., can solve the problems of difficult welding technology, difficult construction, hoisting and transportation, and heavy weight, so as to achieve a high degree of intensive production and reduce space constraints , the effect of broad industry promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

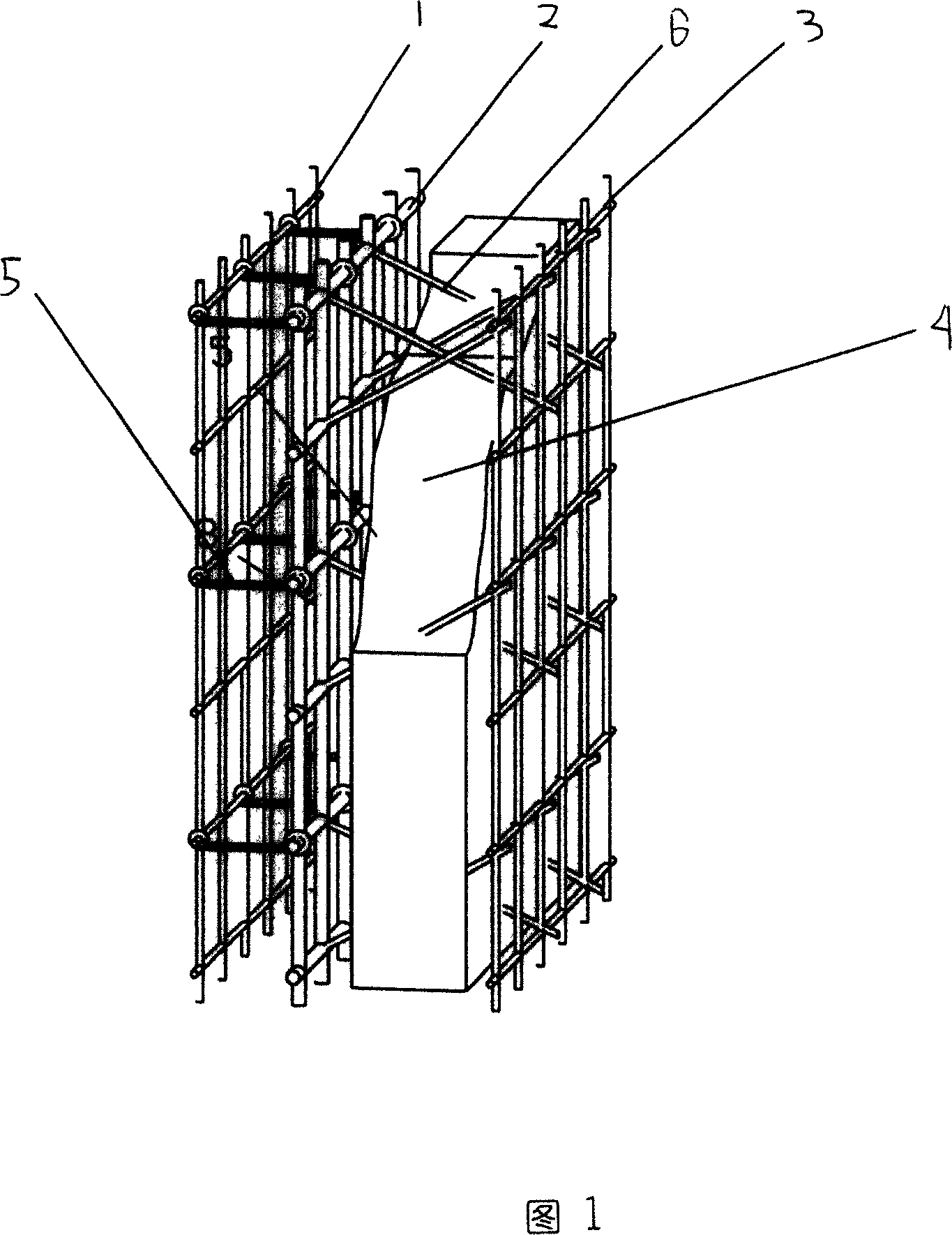

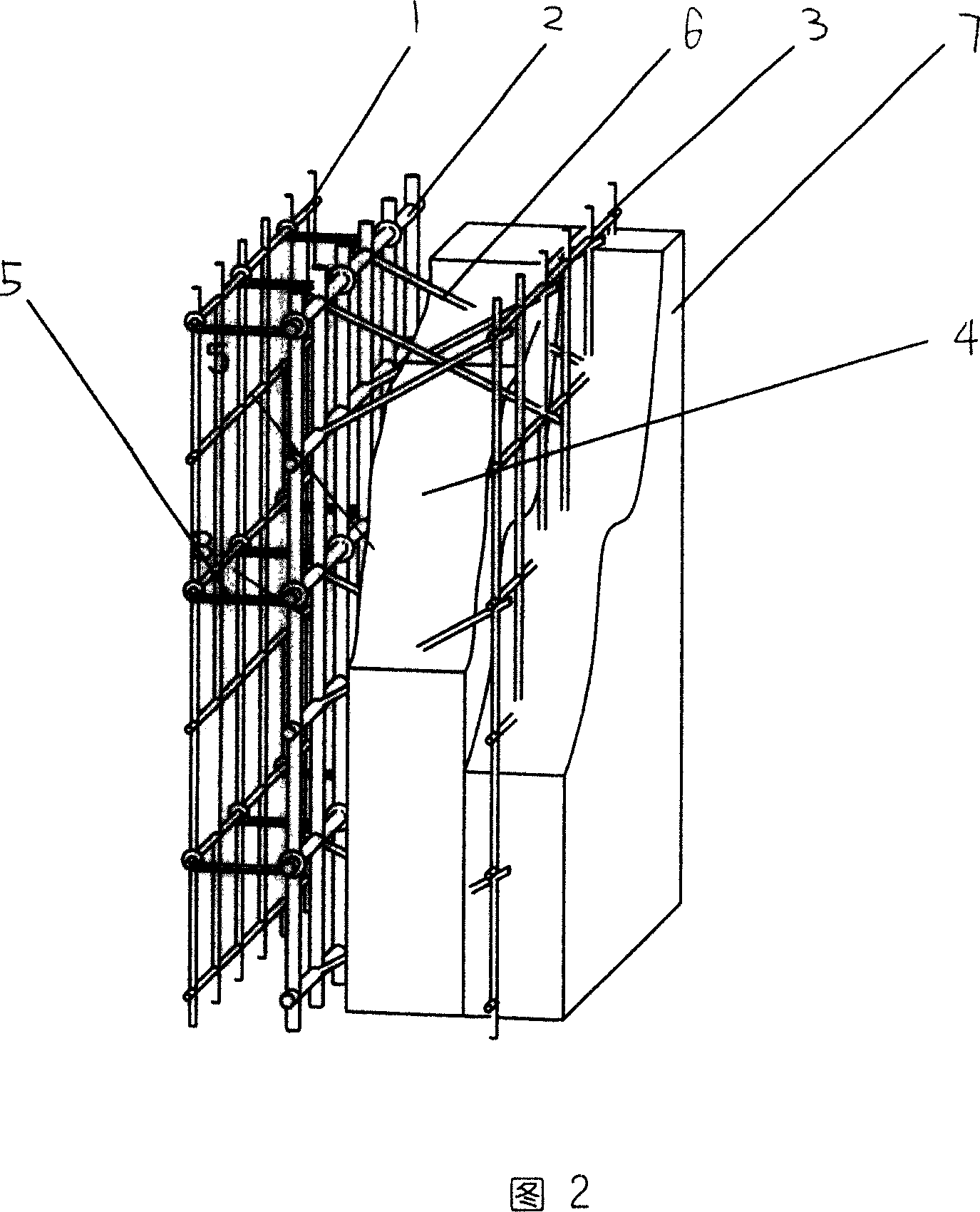

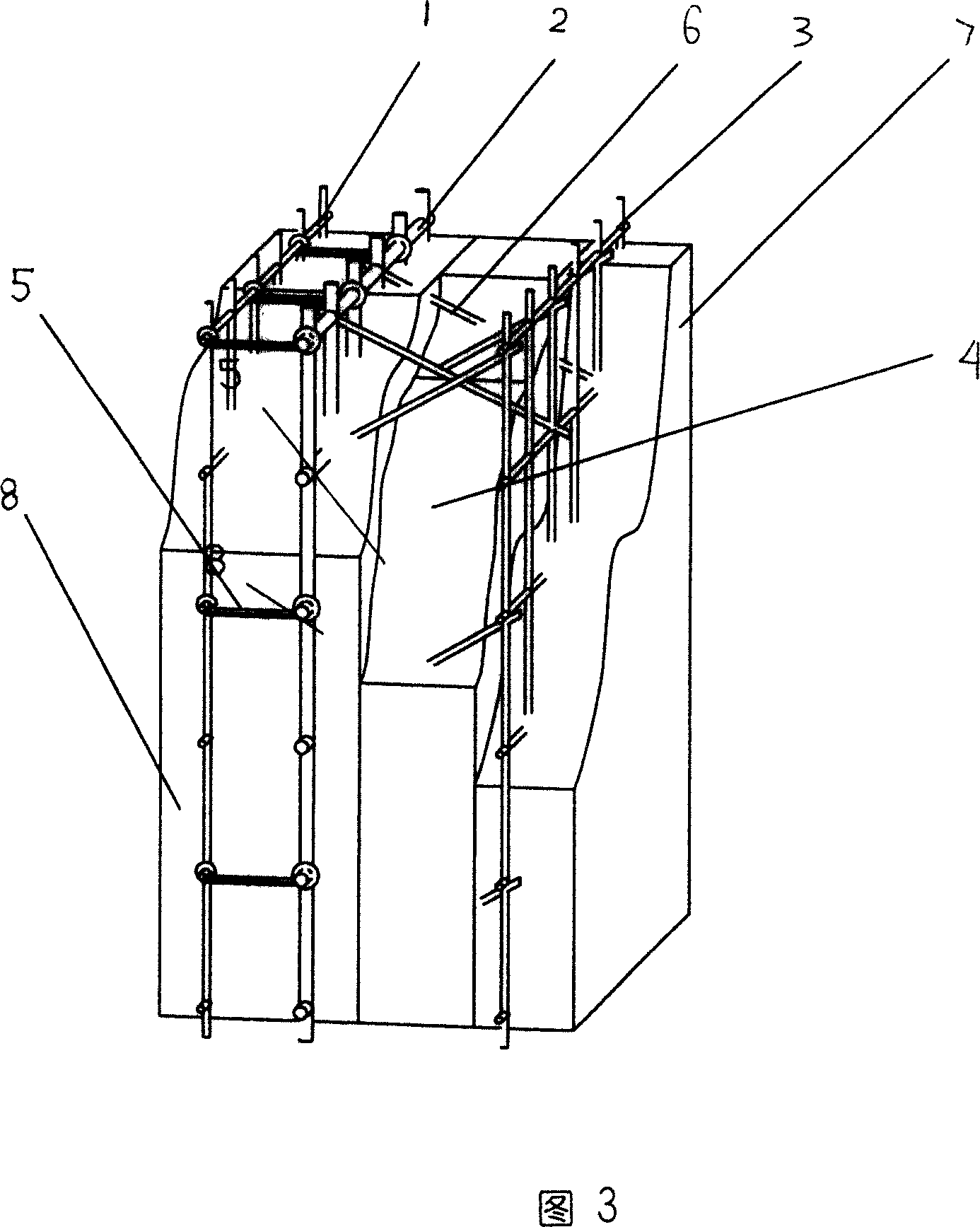

[0021] The design feature of the composite shear wall skeleton with combined reinforced steel bars shown in Figure 1 is to highlight the load-bearing structure of the slab. The cross-linked steel bar is composed of two-layer steel bar flat screens 2, 3 and cable-stayed steel bars 6 that are welded and staggered. The core plate 4 is set at the offset center, one side is used as the main stress reinforcement of the shear wall, and the other side is fixed with an insulation layer. The main stress reinforcement flat net 2 is formed by hanging one or more layers of reinforcement flat net 1 outside the hook 5. After the formwork is fixed on site, concrete 7 and 8 are poured on both sides to form a composite reinforced concrete shear wall, in which one side of the external reinforced flat mesh is used as a load-bearing wall, and the other side is used as a composite thermal insulation wall.

[0022] As shown in Figure 1, the oblique wires of the composite shear wall frame with connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com