Fixture and method for uniform electroless metal deposition on integrated circuit bond pads

a technology of electroless plating and bonding pads, which is applied in the direction of liquid/solution decomposition chemical coating, semiconductor/solid-state device details, coatings, etc., can solve the problems of significant technological challenges, pronounced aluminum sensitivity to electromigration becoming a serious obstacle, and the need for expensive photolithographic definition steps. to avoid the effect of expensive photolithographic definition steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

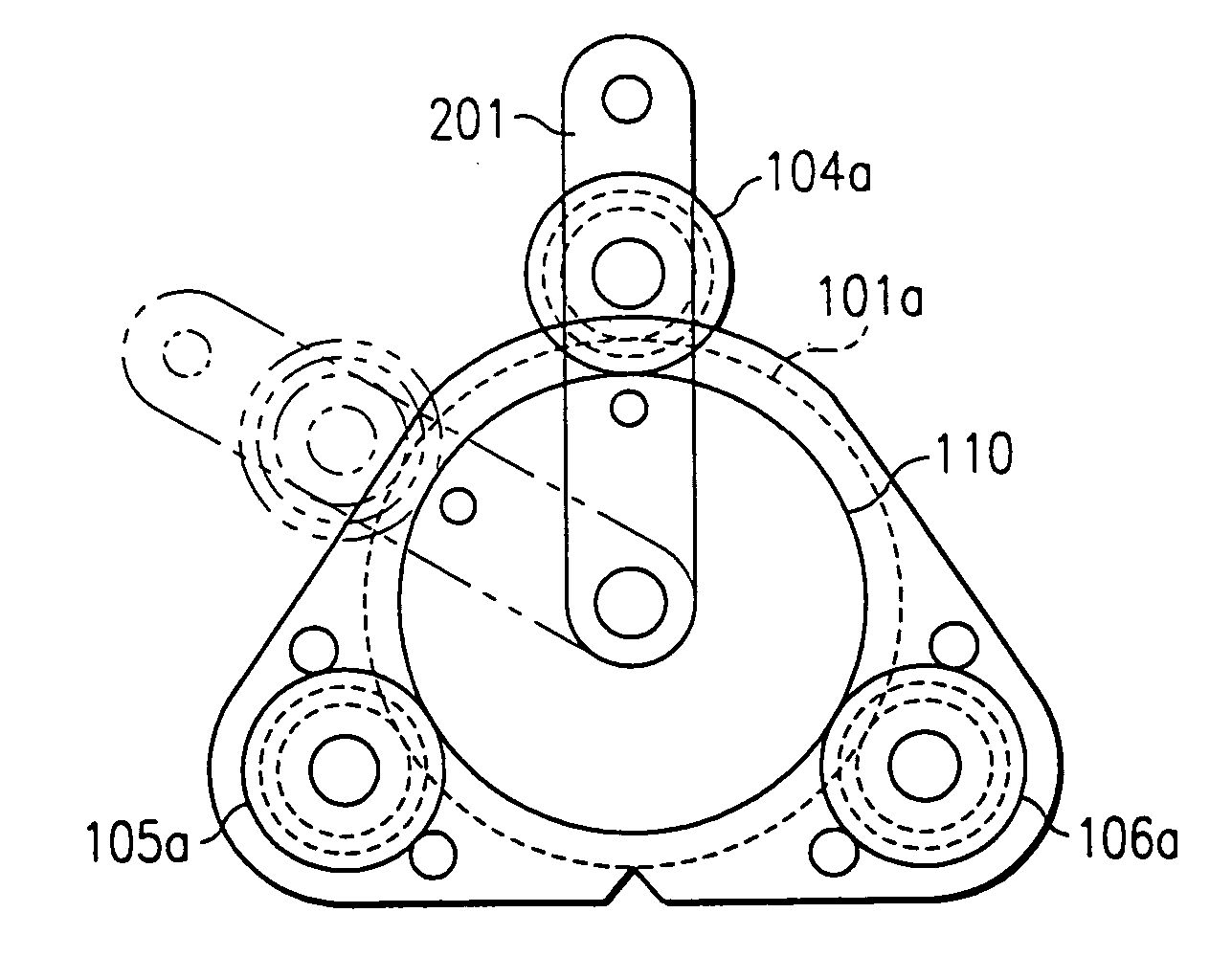

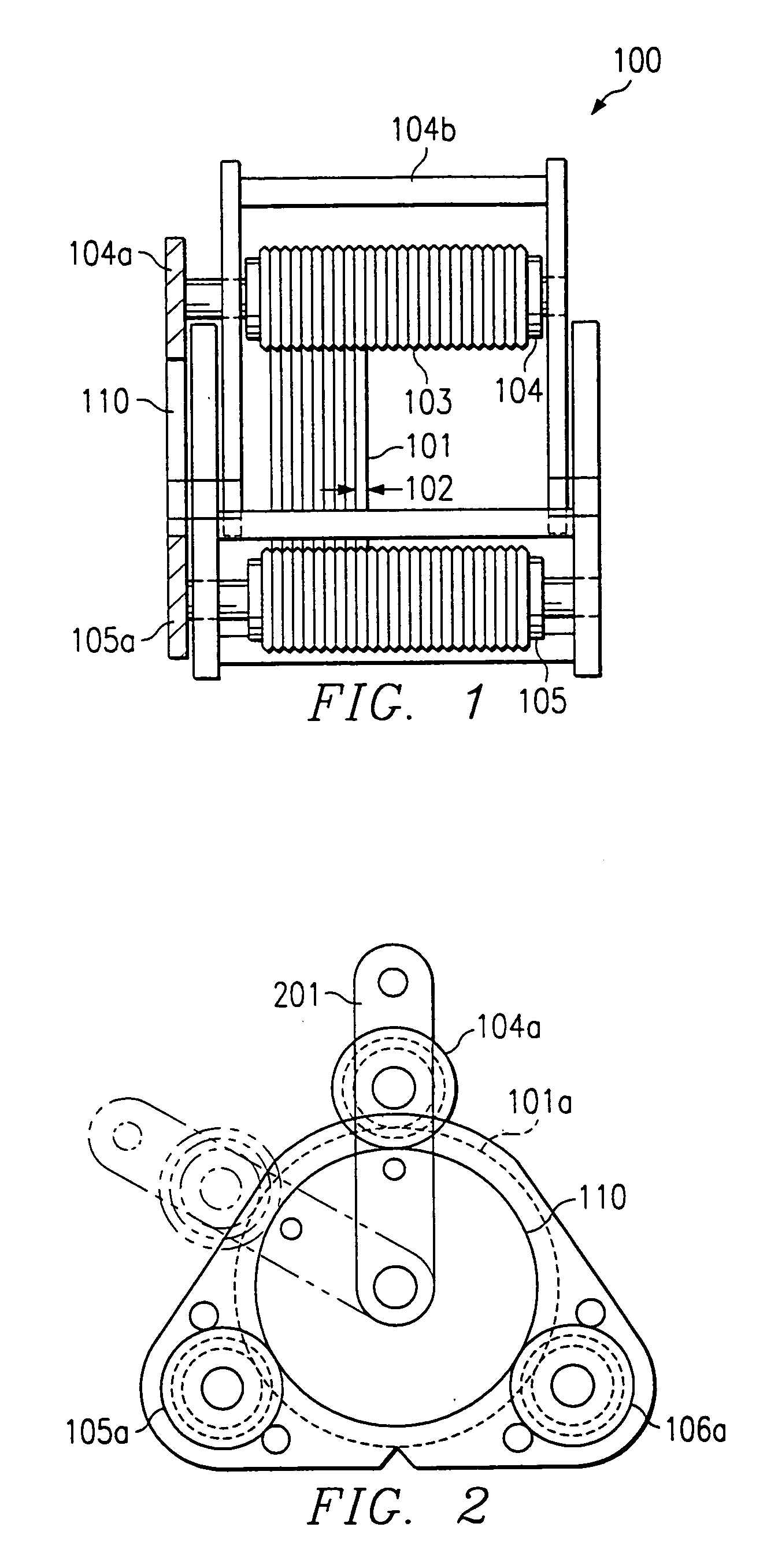

[0027] Illustrating the invention, generally designated 100, FIG. 1 shows a side view of the apparatus for controlled electroless plating of uniform metal layers onto exposed metallizations on a plurality of integrated circuit (IC) wafers 101. Usually, there are 10 to 30 wafers in a batch. In the fixture 100, the wafers 101 are held approximately parallel to each other at predetermined distances 102. A typical distance is in the range from about 5 to 10 mm and thus several times wider than the thickness of a wafer (about 0.25 to 0.75 mm). At their rims, the wafers are loosely held in grooves 103 of rollers. In FIG. 1, two rollers are shown, the bottom roller 105 and the capture roller 104. The rollers are made of chemically inert plastic material such as polypropylene. Instead of grooved rollers, toothed rollers may be used. A practical groove is about 2 to 5 mm deep. In the preferred embodiments, there are three rollers (see FIG. 2) employed to contain the wafers.

[0028] It is an es...

second embodiment

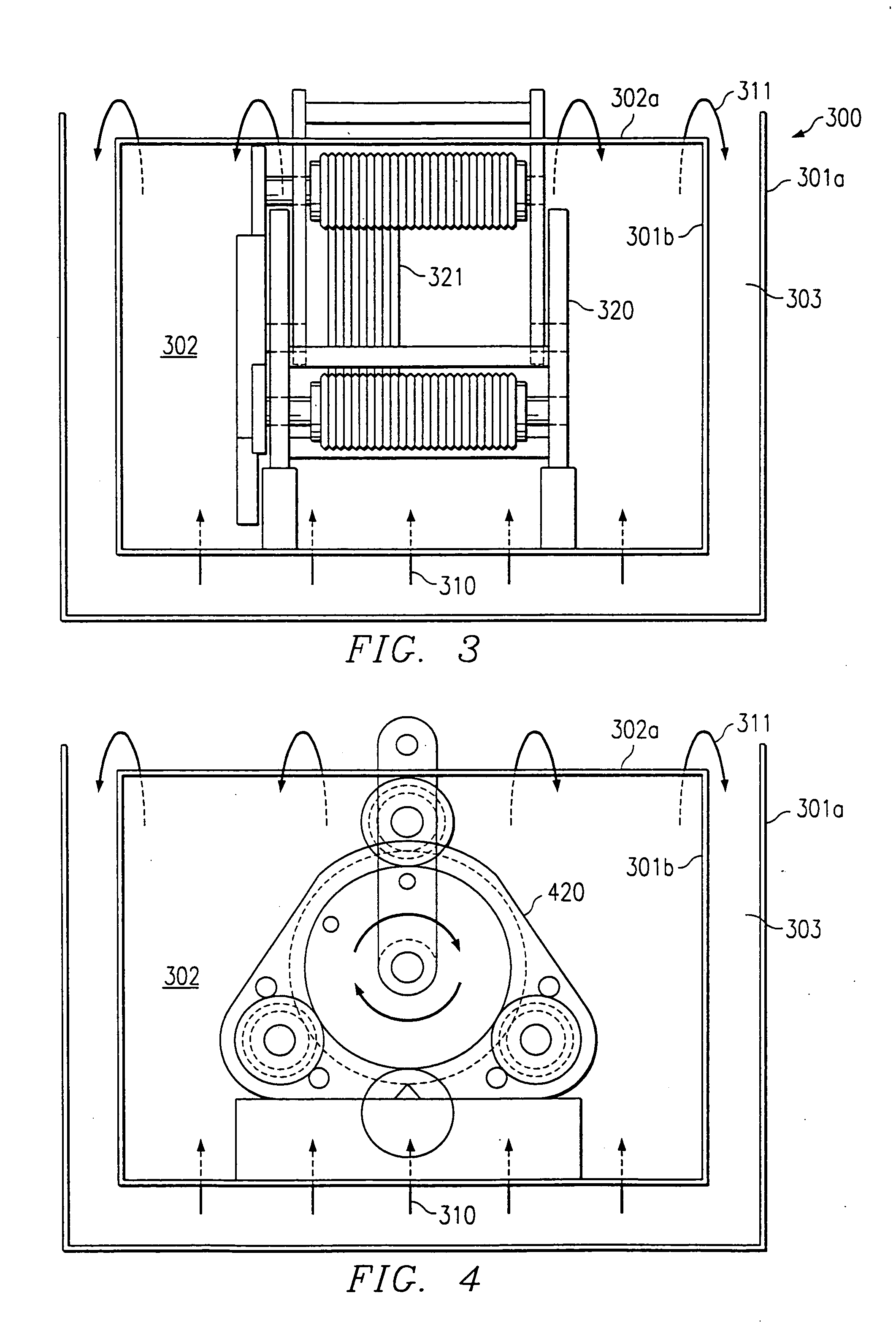

[0030] Illustrating the invention, generally designated 300, as well as the process for electroless plating, FIGS. 3 and 4 show schematically the cross section through a plating tank filled by the liquid plating solution 302 up to the surface 302a of the solution. The plating tank has an outer wall 301a and an inner wall 301b, separated by a gap 303, which enables the reflow of the liquid. In FIGS. 3 and 4, arrows indicate the flow of the liquid solution. As can be seen, the solution enters the tank from the bottom (arrows 310), moves in laminar flow at constant speed upward (for example, at a speed of 20 cm / min) through the tank, and exits from the tank surface (arrows 311) by overflowing into the reflow gap 303. After reaching the tank bottom, the flow cycle begins anew.

[0031] Further shown in FIGS. 3 and 4 is the apparatus / fixture for holding a plurality of wafers, explained in FIGS. 1 and 2. In FIG. 3, the fixture is illustrated in side view 320 as in FIG. 1; in FIG. 4, the fixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com