Compactly designed membrane-type coupling

A coupling and membrane technology, which is applied in the field of membrane couplings, can solve the problems of large space of membrane couplings and achieve the effect of reducing the installation length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

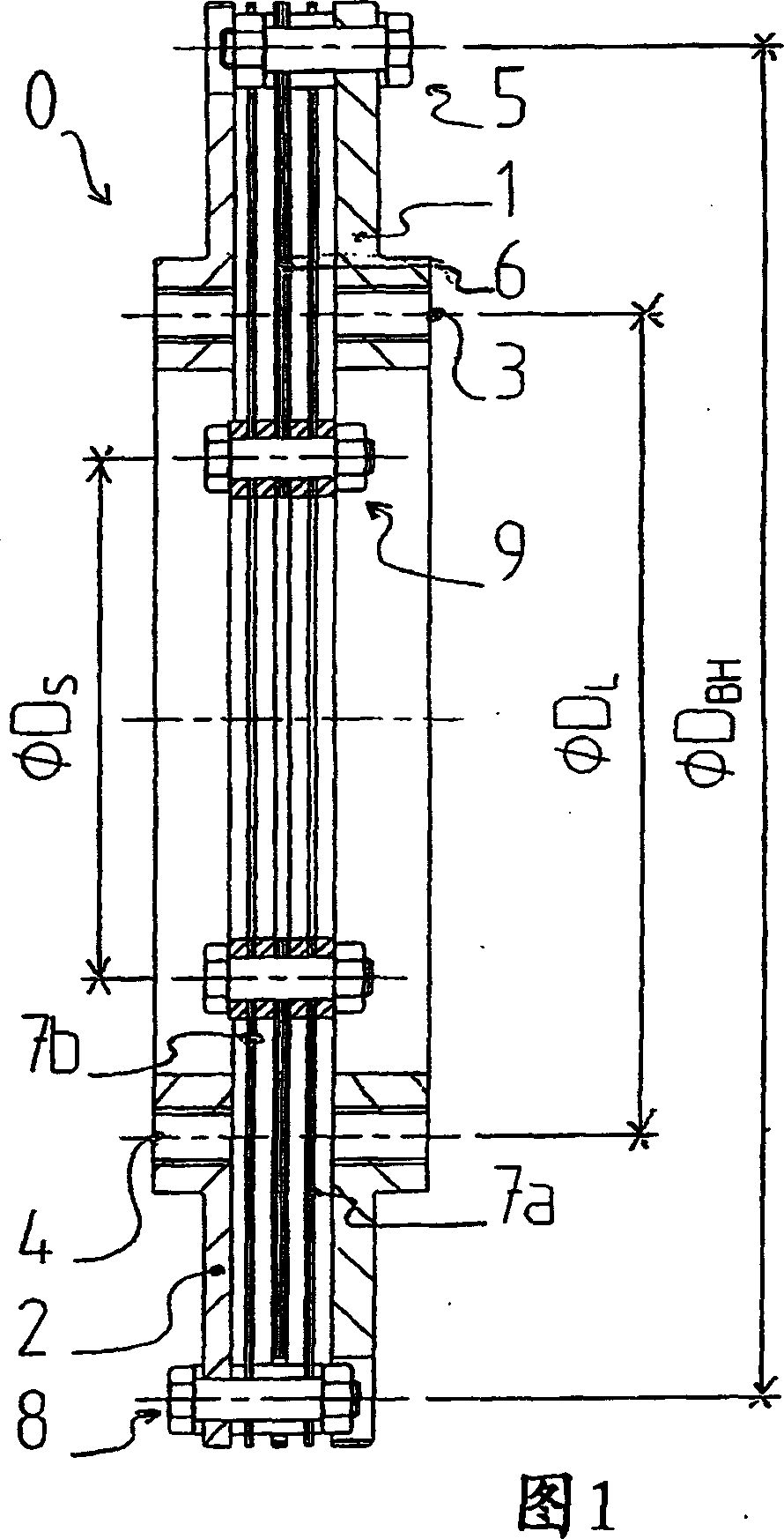

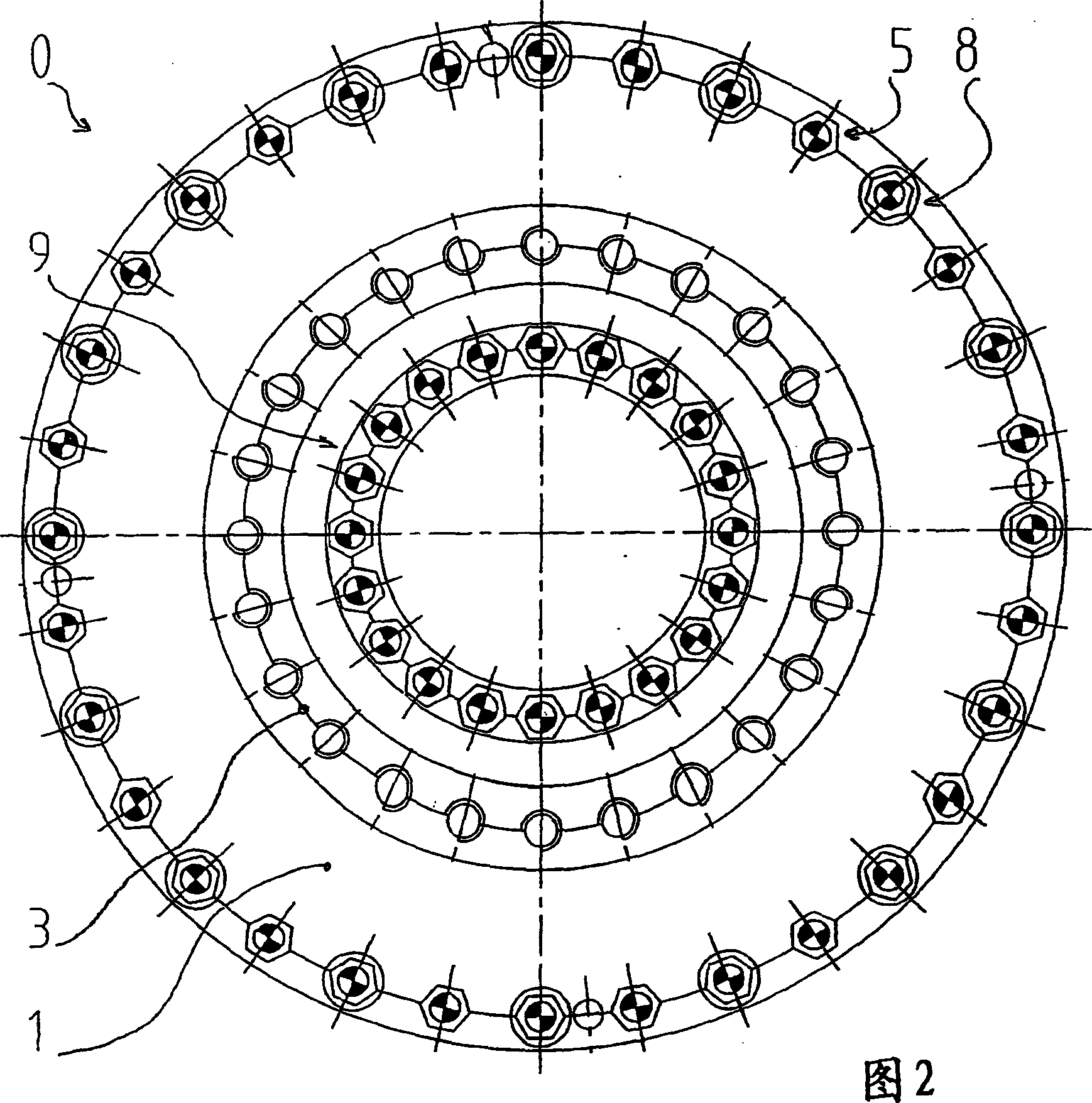

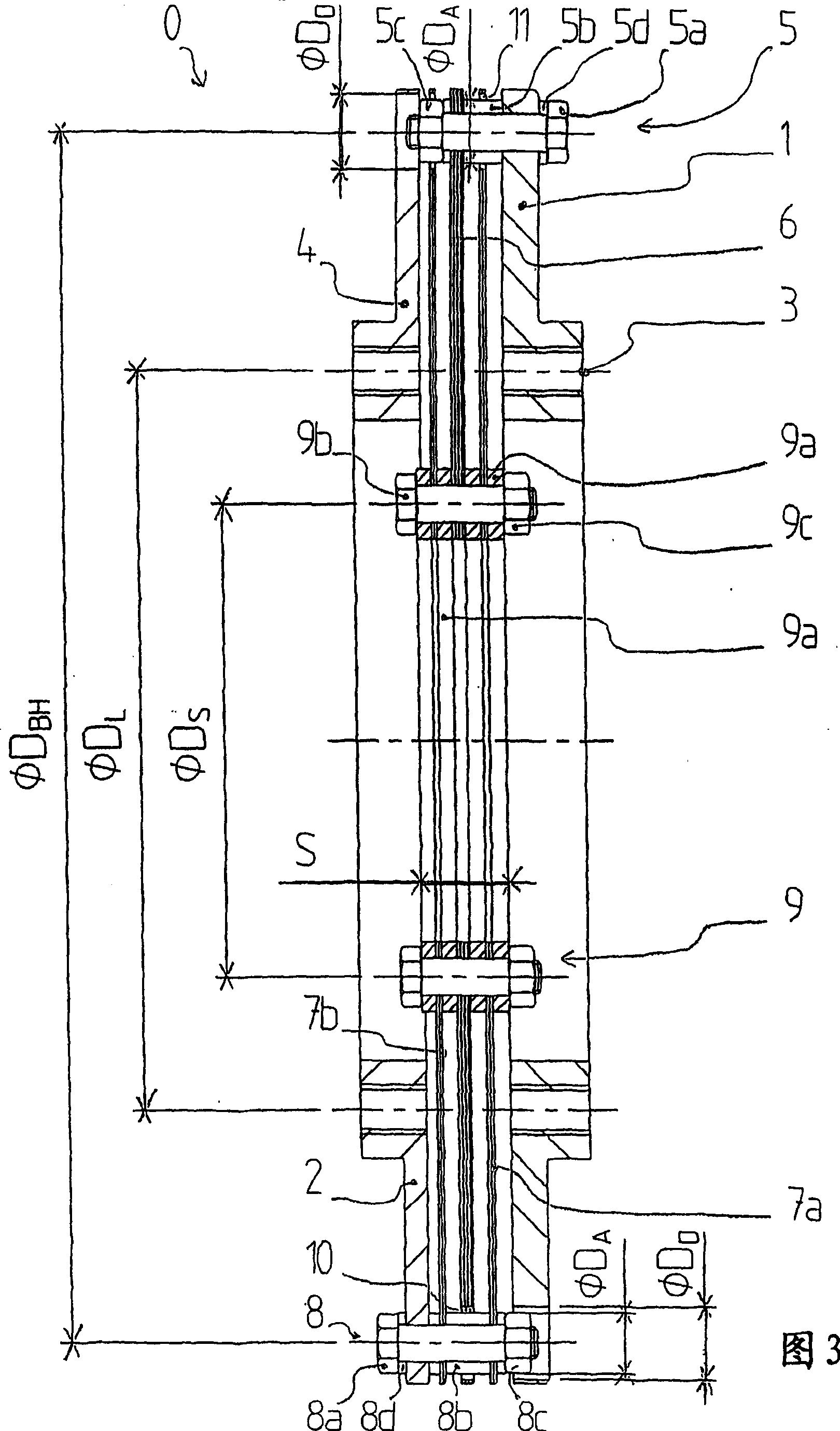

[0017] The membrane coupling is denoted as a whole by the reference numeral 0 . The membrane coupling consists of an input flange 1 and an output flange 2. The flanges 1 , 2 are each equipped with an input perforated disc 3 or an output perforated disc 4 , by means of which the membrane coupling 0 can be connected to machine elements arranged before or after the drive rod. The two perforated discs 3, 4 are concentric with the flanges aligned. In this embodiment the two porous disks 3, 4 have the same diameter D L . For specific application purposes, it can be considered to design the porous discs 3, 4 with different diameters D L . The first type of bolt / sleeve configuration 5 is set at a larger diameter D BH superior.

[0018] A bolt / sleeve arrangement 5 of the first type comprises a bolt 5a, two bushes 5b, a nut 5c and a washer 5d. The input diaphragm pack 6 is fastened to the input flange 1 by means of a first type of screw / sleeve arrangement 5 . The input diaphragm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com