Roller coiling drum, functional lining for a roller coiling drum, roller coiling device and method for coiling a material sheet

A technology of winding device and winding roller, especially applied in the field of winding device of paper web or cardboard web, winding material web, and functional layer of winding roller, which can solve the problems of expensive manufacturing and maintenance cost, and achieve Effect of smooth winding process, economical handling, high quality winding results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

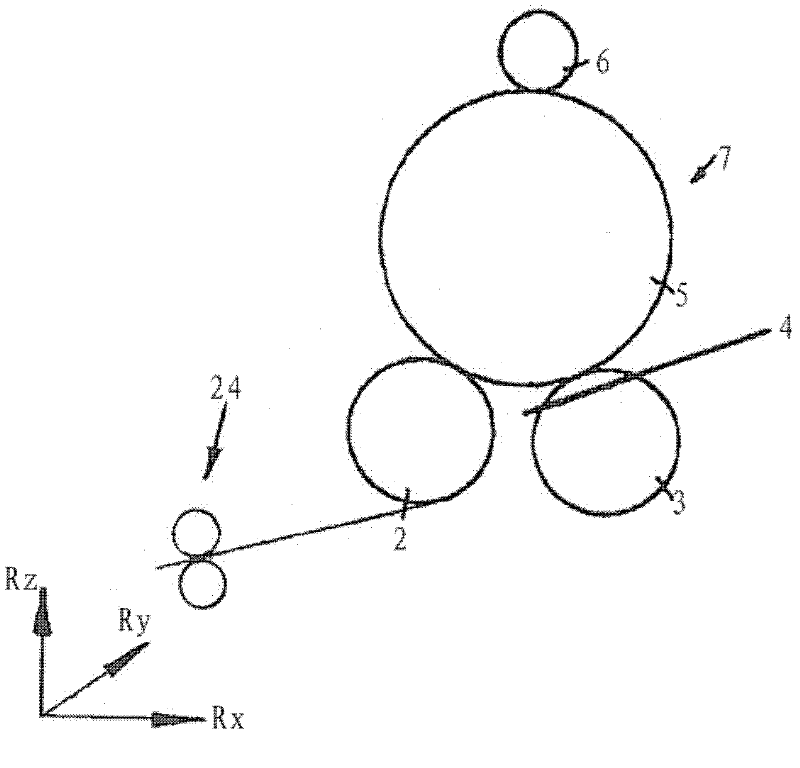

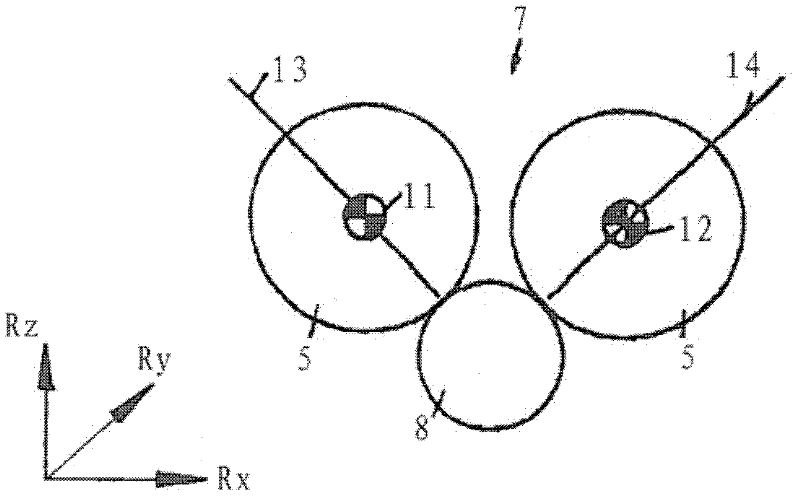

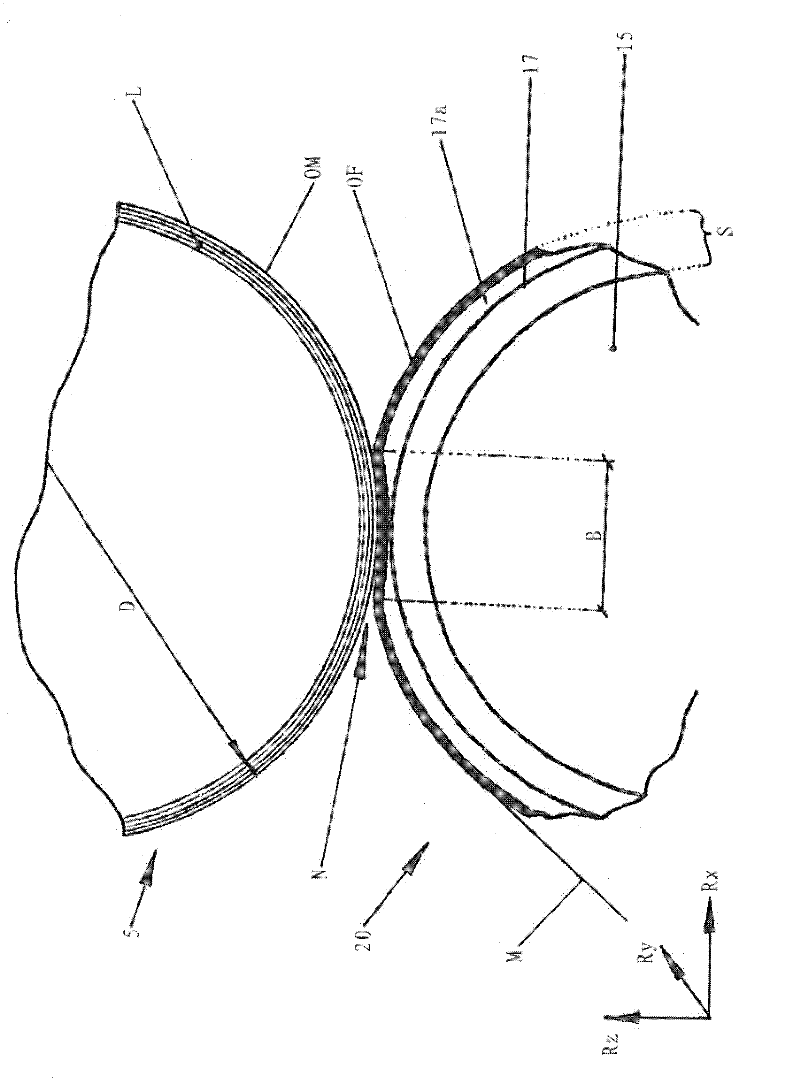

[0073] Figure 1a Shown is a winding device 1 in the form of a double idler winding device, which will also be referred to below simply as an idler winding machine, and has a first idler roller 2 and a view in the web running direction Rx The second supporting rollers 3, said supporting rollers together form a winding bed 4 in which the material roll 5 is located. Of course, a plurality of rolls 5 can also be arranged side by side in the winding bed 5 in the axial direction Ry. At least one idler roller 2, 3 is driven. If the support rollers 2, 3 rotate, then the roll 5 is entrained by friction and thus the web M, for example a paper web, is pulled. The winding device 1 has a cutting section 24 arranged in front of the winding bed 4 for dividing the running web M longitudinally.

[0074] In order to prevent the roll 5 from jumping out of the winding bed 4 and to create a certain winding stiffness for starting the winding, a load roll 6 is arranged above the winding bed 4 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com