Medium high temperature heat pump work substance

A high-temperature heat pump, working fluid technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc.

Inactive Publication Date: 2007-04-18

TIANJIN UNIV

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to overcome the shortcomings of the existing non-azeotropic R22 substitutes such as component migration, and develop an azeotropic or near-azeotropic mixing substitute with high safety performance, good environmental acceptance performance, thermal performance and refrigeration cycle performance similar to R22 quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0012] Example 1: Take 15% R32, 20% DME, and 65% R134a, and physically mix these three components at room temperature as a refrigerant.

Embodiment 2

[0013] Example 2: Take 40% R32, 10% DME, and 50% R134a, and physically mix these three components at room temperature as a refrigerant.

Embodiment 3

[0014] Example 3: Take 30% R32, 15% DME, and 55% R134a, and physically mix these three components at room temperature as a refrigerant.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

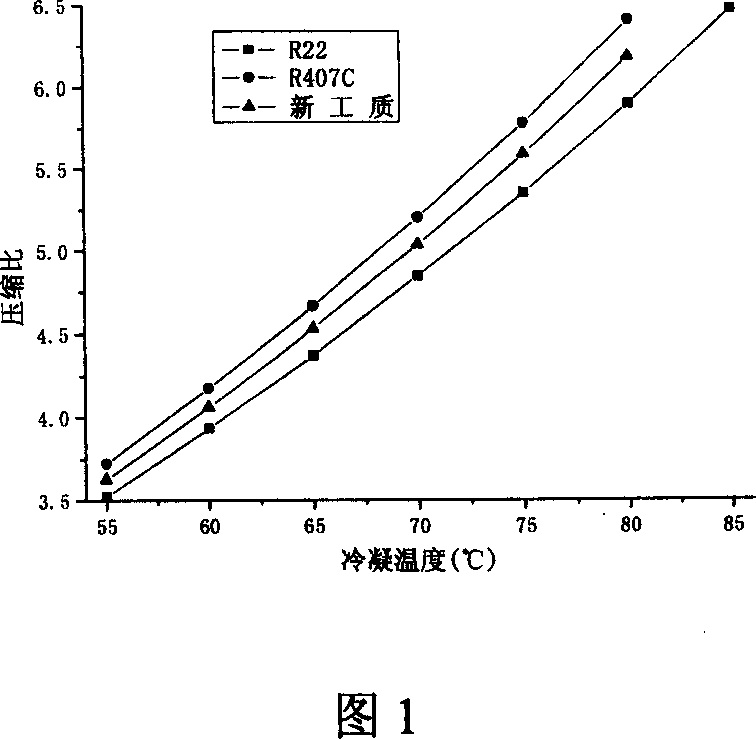

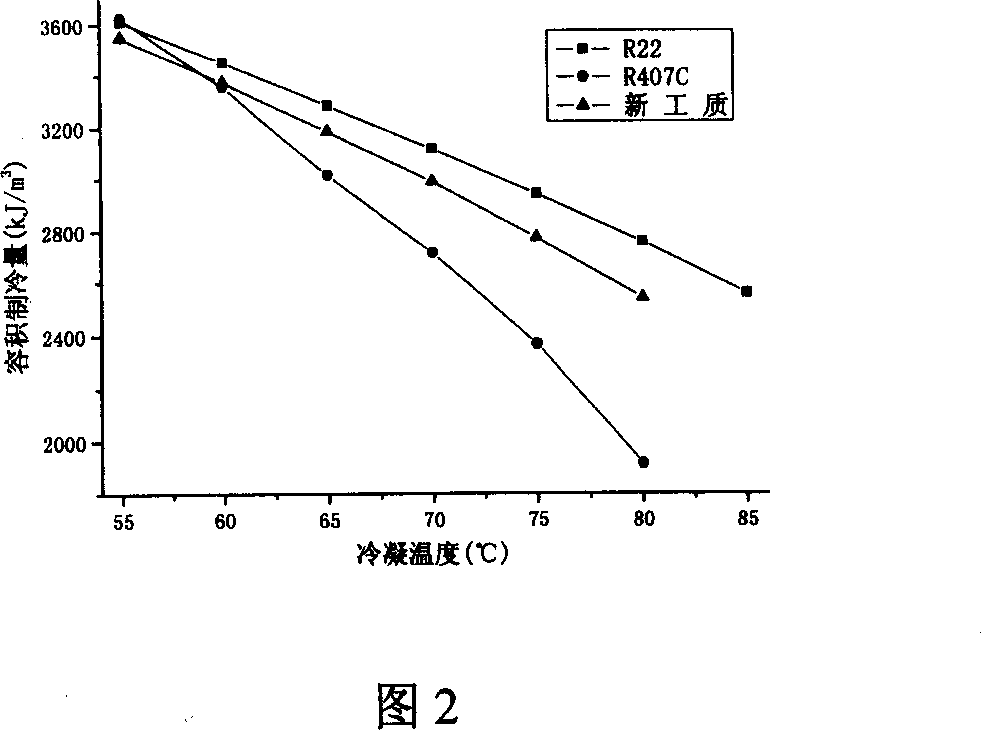

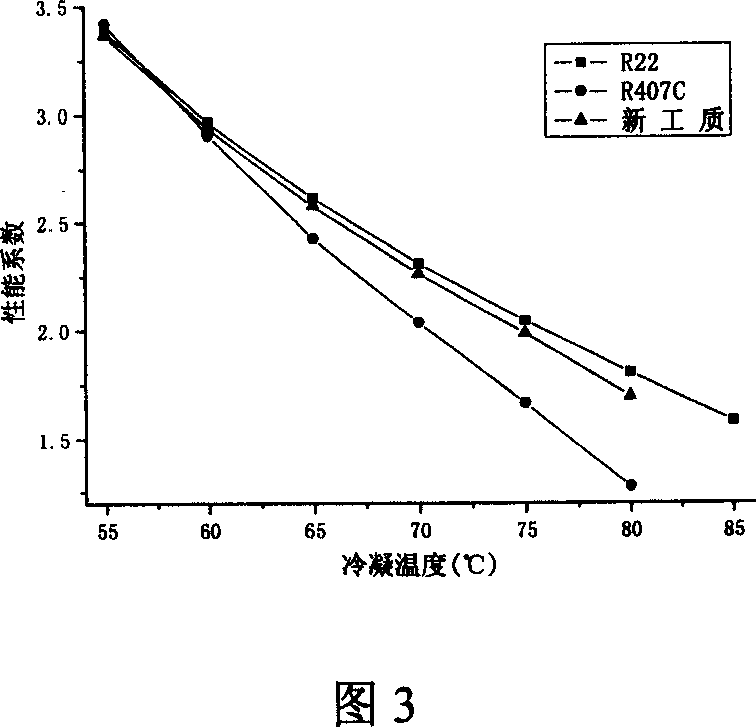

This invention provides a medium high temperature heat pump which belongs to refrigeration, air conditioning and heat pump system. This neotype medium high temperature heat pump composed by three compounds, and they are difluoromethane(R32), dimethyl ether(DME), 1,1,1,2-tetra fluoro ethane(R134a), and its weight percentage content is that R32 15-45%, DME 10-35%, R134a 35-65%. Either base operation condition or alternated working condition, the heat engineering and circulation performance of this invention is similar to monochlorodifluoromethane(R22). Compared with R407C the replacement of R22, the invention is more environmental protective, and its ozone layer destroy potency(ODF) is zero, and its greenhouse effect greenhouse effect (GWP) is more lower, and its medium high temperature alternated working condition is better, and its slippage temperature is lower, and it can also solve many kinds of problems caused by composition migration.

Description

technical field [0001] The invention belongs to medium and high temperature heat pump working medium in refrigeration, air conditioning and heat pump systems. Background technique [0002] Since its commercial production in 1936, chlorodifluoromethane (R22) has been widely used in the field of refrigeration and air conditioning due to its excellent comprehensive performance. The "Protocol" stipulates that developed countries use R22 as a refrigerant for new refrigeration air-conditioning heat pump equipment to use R22 until 2020, existing equipment can be used until 2030, and developing countries are allowed to use it until 2040. However, on the one hand, the process of refrigerant replacement is accelerating, and many countries, especially European countries, have adopted stricter restrictive measures to advance the phase-out date; on the other hand, China has joined the World Trade Organization (WTO). Competitiveness in overseas markets enables ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K5/04

Inventor 杨昭彭继军方筝王明涛

Owner TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com