A kind of production method of normal temperature fluorine-free foaming neutral phenolic foam

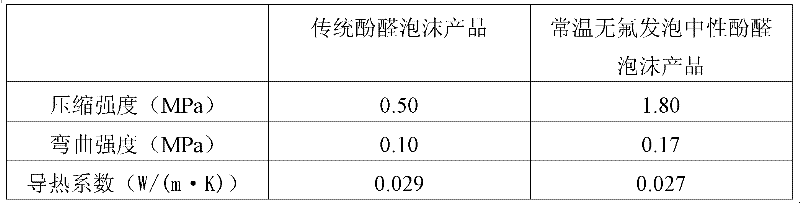

A technology of phenolic foam and production method, which is applied in the field of polymer organic compounds, can solve problems such as low strength, difficult on-site implementation, and ozone layer destruction, and achieve the effects of improved compressive strength or bending strength, wide application range, and reduced thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1), get 250kg of phenol, 70kg of industrial paraformaldehyde, 2kg of oxalic acid, 1kg of hydrochloric acid, and 200kg of water for subsequent use;

[0028] (2), add phenol, oxalic acid, hydrochloric acid, water prepared in step (1) in the reaction kettle, heat up to 60~85 ℃, slowly add the industrial paraformaldehyde prepared in step (1) within 1 hour, the feeding process keeps 60 ~85°C temperature, heat up to 90-95°C after feeding, keep warm for 40 minutes, add 0.6kg of ammonia water for neutralization treatment, then use conventional methods to dehydrate 90kg, cool down to 40°C, and obtain thermoplastic phenolic resin for use;

[0029] (3), get phenol 250kg, industrial paraformaldehyde 130kg, sodium hydroxide 1kg, urea 10kg, water 200kg standby;

[0030] (4), phenol, sodium hydroxide and water prepared in step (3) are added in the reaction kettle, and the temperature is raised to 60~85° C., and the industrial paraformaldehyde prepared in step (3) is slowly added in 1...

Embodiment 2

[0036] (1), get phenol 500kg, industrial paraformaldehyde 128kg, oxalic acid 5kg, hydrochloric acid 4kg, water 240kg standby;

[0037] (2), add phenol, oxalic acid, hydrochloric acid, water prepared in step (1) in the reaction kettle, heat up to 60~85 ℃, slowly add the industrial paraformaldehyde prepared in step (1) within 1 hour, the feeding process keeps 60 ~85°C temperature, heat up to 90-95°C after feeding, keep warm for 90 minutes, add 3kg of ammonia water for neutralization treatment, then use conventional methods to dehydrate 120kg, cool down to 40°C, and obtain thermoplastic phenolic resin for use;

[0038] (3), get phenol 500kg, industrial paraformaldehyde 300kg, sodium hydroxide 5kg, urea 20kg, water 240kg standby;

[0039] Step (4) is with embodiment 1;

[0040] (5) Raise the temperature in the reactor to 95-105° C., and keep the temperature at 95-105° C. for 60 minutes. Then use conventional method to dehydrate 120kg. After the dehydration is complete, cool dow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com