Photoetching machine table, developing apparatus and developing process thereof

A development device and a development method technology, applied in the field of photolithography, capable of solving problems such as inconsistencies in critical dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

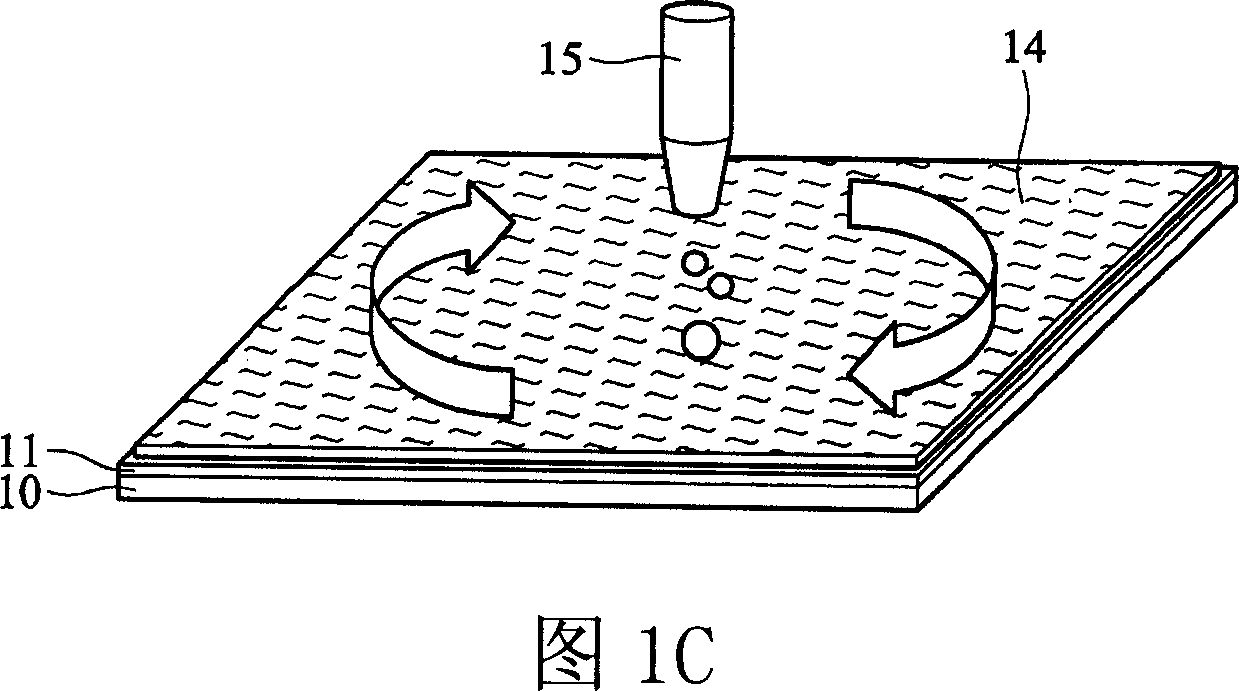

[0024] In the embodiment of the present invention, as shown in FIG. 2A , first, the substrate 20 is fixed by the platform 1 . There is an exposed photoresist 21 above the substrate 20 , and a recovery tank 3 can be provided below to recover the unexposed photoresist or the organic solvent used in the developing process. Above the exposed photoresist 21 is the fluid injector 20 of the present invention.

[0025] FIG. 2B is a top view of FIG. 2A. The material of the substrate 20 includes light-transmitting materials (such as: glass, quartz or similar materials), opaque materials (such as: silicon, ceramics or similar materials), or flexible materials (such as: plastics, rubber, polyester class, polyolefin, polyacyl or similar materials or a mixture of the above), the embodiments of the present invention take a glass substrate as an example. In addition, the structure on the surface of the substrate 20 may be any layer of a circuit structure or a filter structure. On the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com