Optical close range correction, photo mask production and graphic method

An optical short-distance and reticle technology, which is applied in the photoplate process of optics and patterned surfaces, and originals for photomechanical processing, etc., can solve the problem of large differences in critical dimensions, inconsistent layout circuit graphics density, and impact on semiconductors. Problems such as device imaging quality, to achieve the effect of improving imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

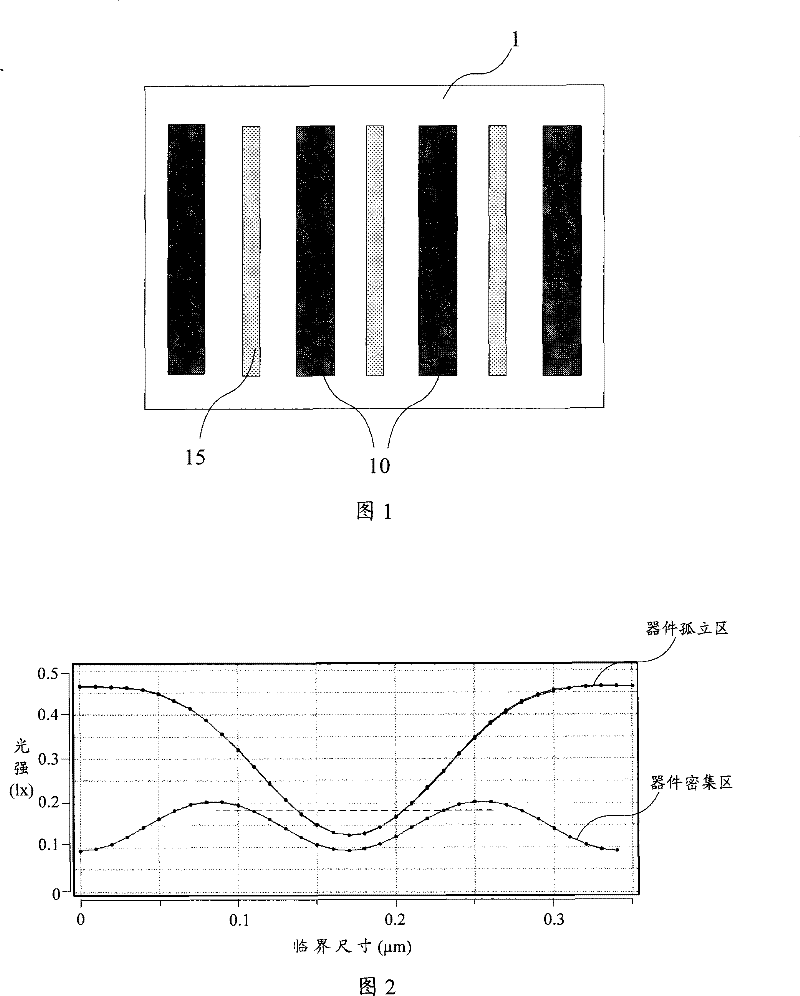

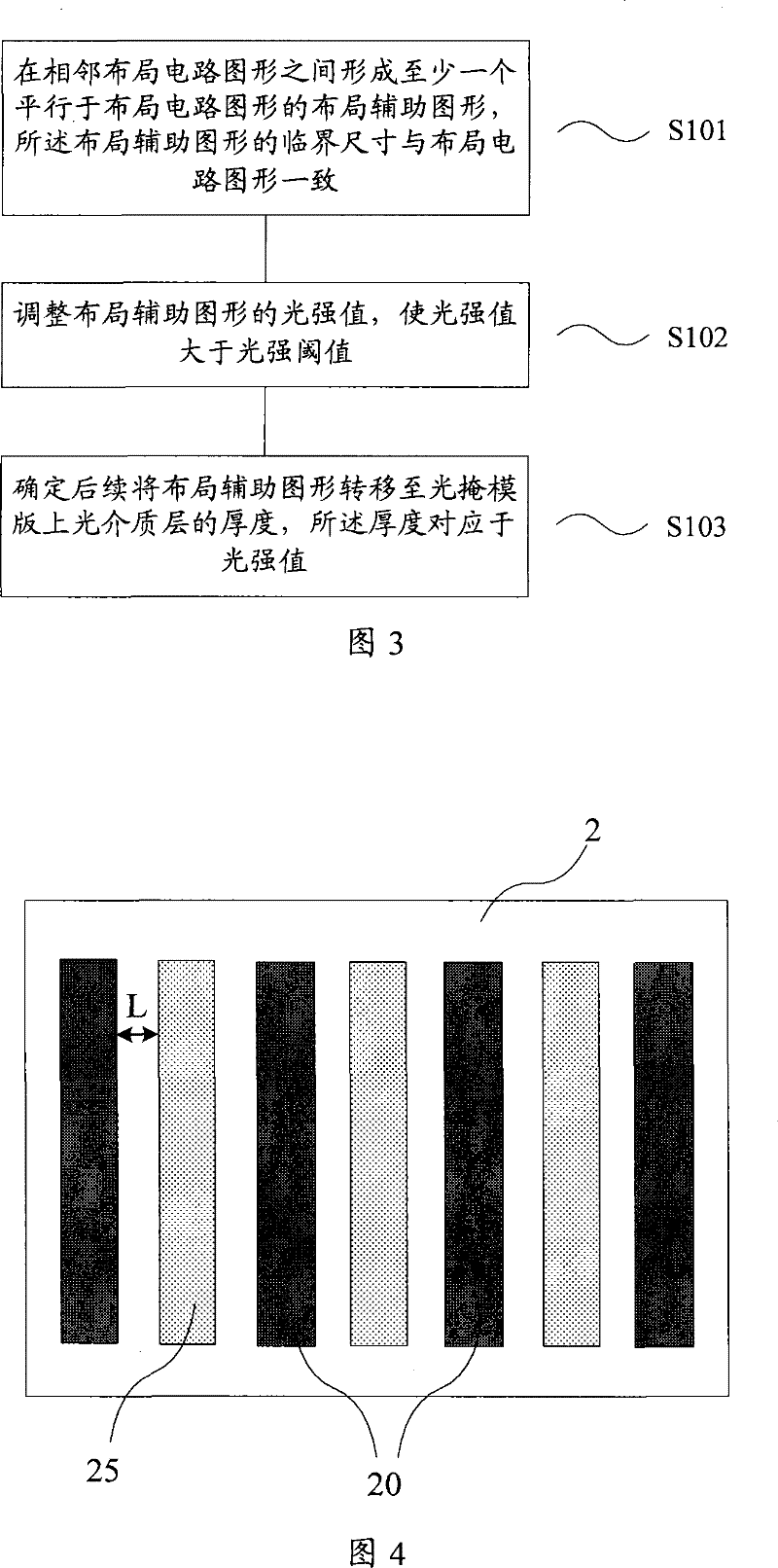

[0033] According to the density of semiconductor devices on the wafer, it can be divided into device-dense area, device semi-dense area and device isolated area. The distance between circuit patterns in the device-dense area is equal to 1CD, and the distance between circuit patterns in the device semi-dense area is greater than 1CD and less than Equal to 3CD, the distance between the circuit patterns in the isolated area of the device is greater than 3CD.

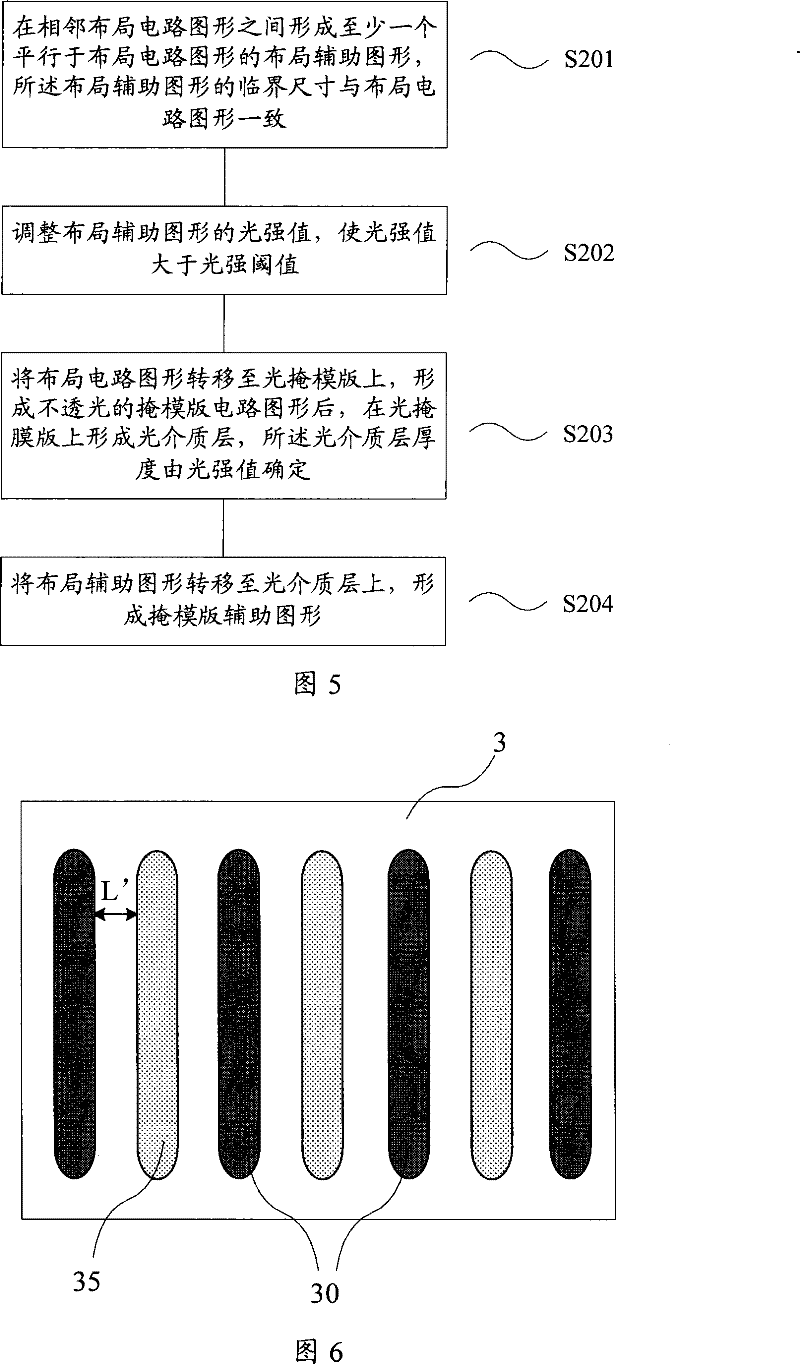

[0034] Forming the circuit pattern on the photoresist layer of the wafer is to use the photomask plate manufacturing equipment to transfer the designed layout circuit pattern to the photomask plate, and then use the exposure device to transfer the reticle circuit pattern on the photomask plate onto the photoresist layer of the wafer. Therefore, adding layout auxiliary patterns around the layout circuit patterns can reduce the CD variation of the circuit patterns formed on the photoresist layer of the wafer.

[0035]In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com