Radial series rotary electric machine

A technology of rotating electrical machines and rotating shafts, applied in synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc., to achieve the effect of increasing flexibility, eliminating adverse effects, and meticulous output control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

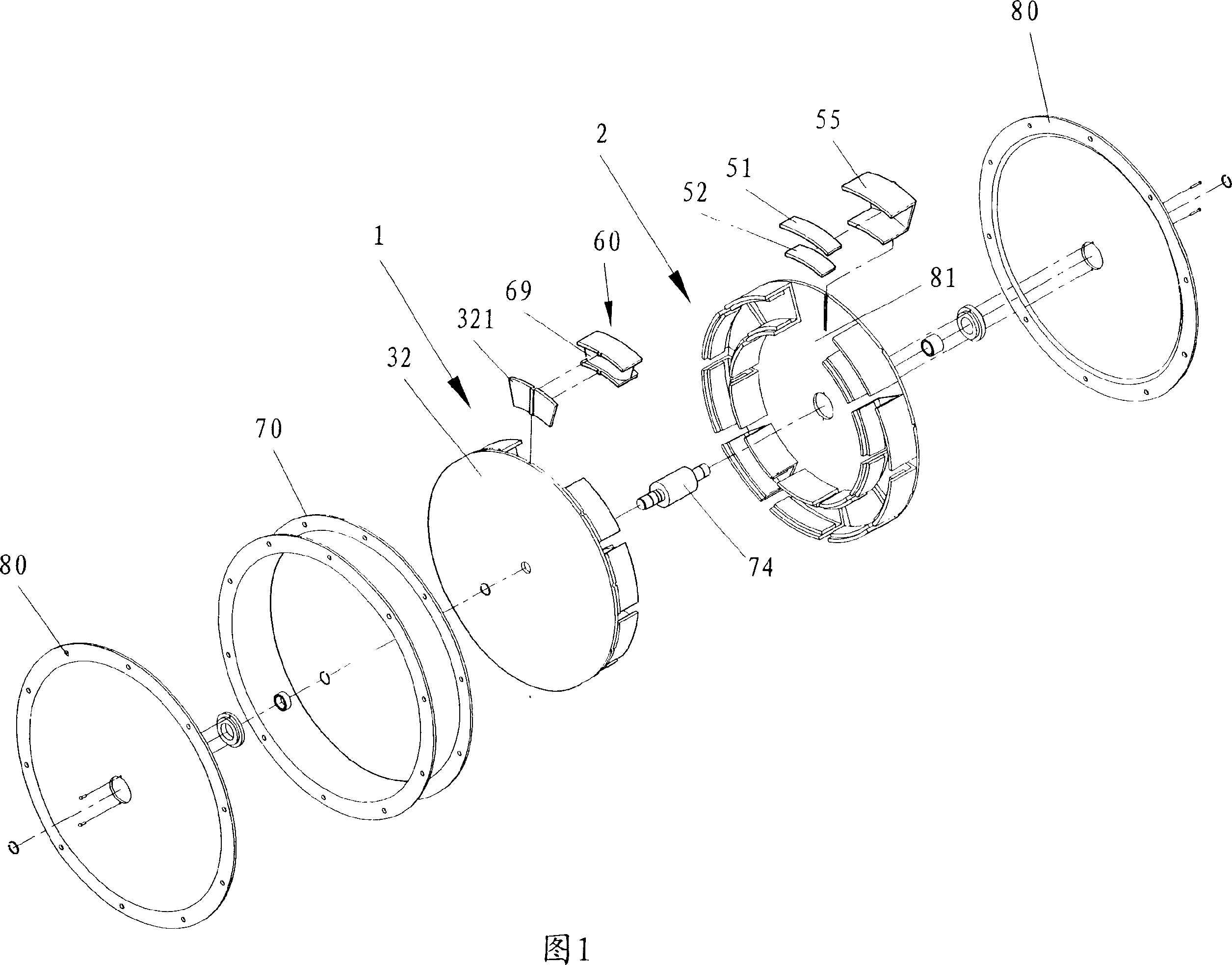

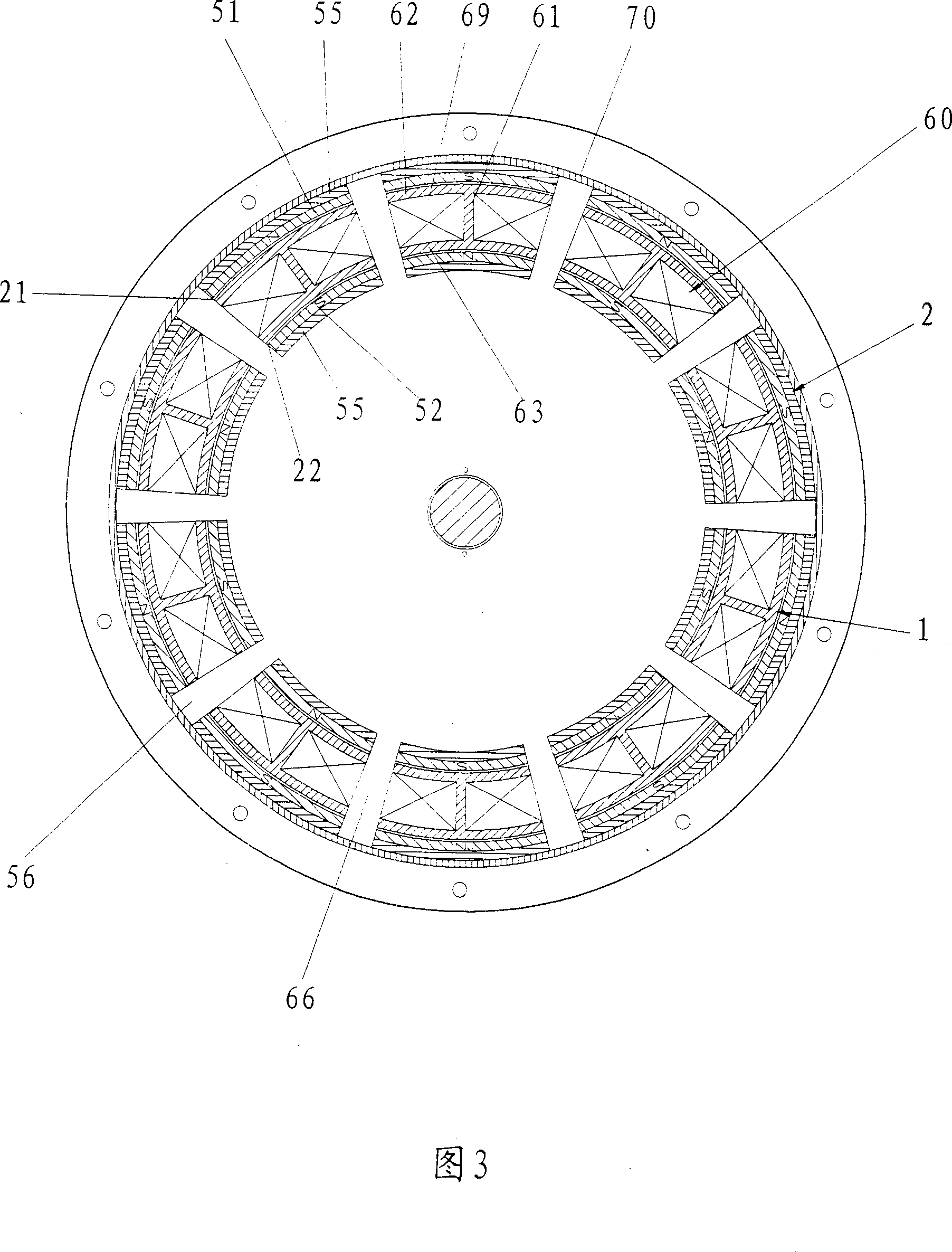

[0051] FIG. 1 is a three-dimensional exploded view of some components of the first embodiment of the present invention before being connected in series to illustrate the components of the rotating electrical machine before being connected in series. The rotating electric machine includes a stator and a rotor. The electromagnet members 60 of the stator that contain coils 69 are placed on the stator fixed disk 32 through the fitting plate 321, and a plurality of electromagnet members 60 are assembled to form the stator wheel ring 1 around a rotating shaft 74; the stator fixed disk 32 and the rotating Shaft 74 incorporates as a support structure for electromagnet member 60 . Each magnetic element of the rotor has a generally U-shaped coupling seat 55 formed of a magnetically permeable material, and the inner surfaces of the two side walls of the U-shaped coupling seat 55 of each magnetic element are respectively arranged to form two magnetic poles of the magnetic element. The pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com