Slurry loaded forest fire-fighting vehicle

A fire truck and mud technology, applied in fire rescue, etc., can solve problems such as inability to spray high-concentration mixed slurry, fire trucks cannot stir and mix, and unfavorable forest firefighting efficiency, achieving manpower saving, easy implementation, and low overall cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

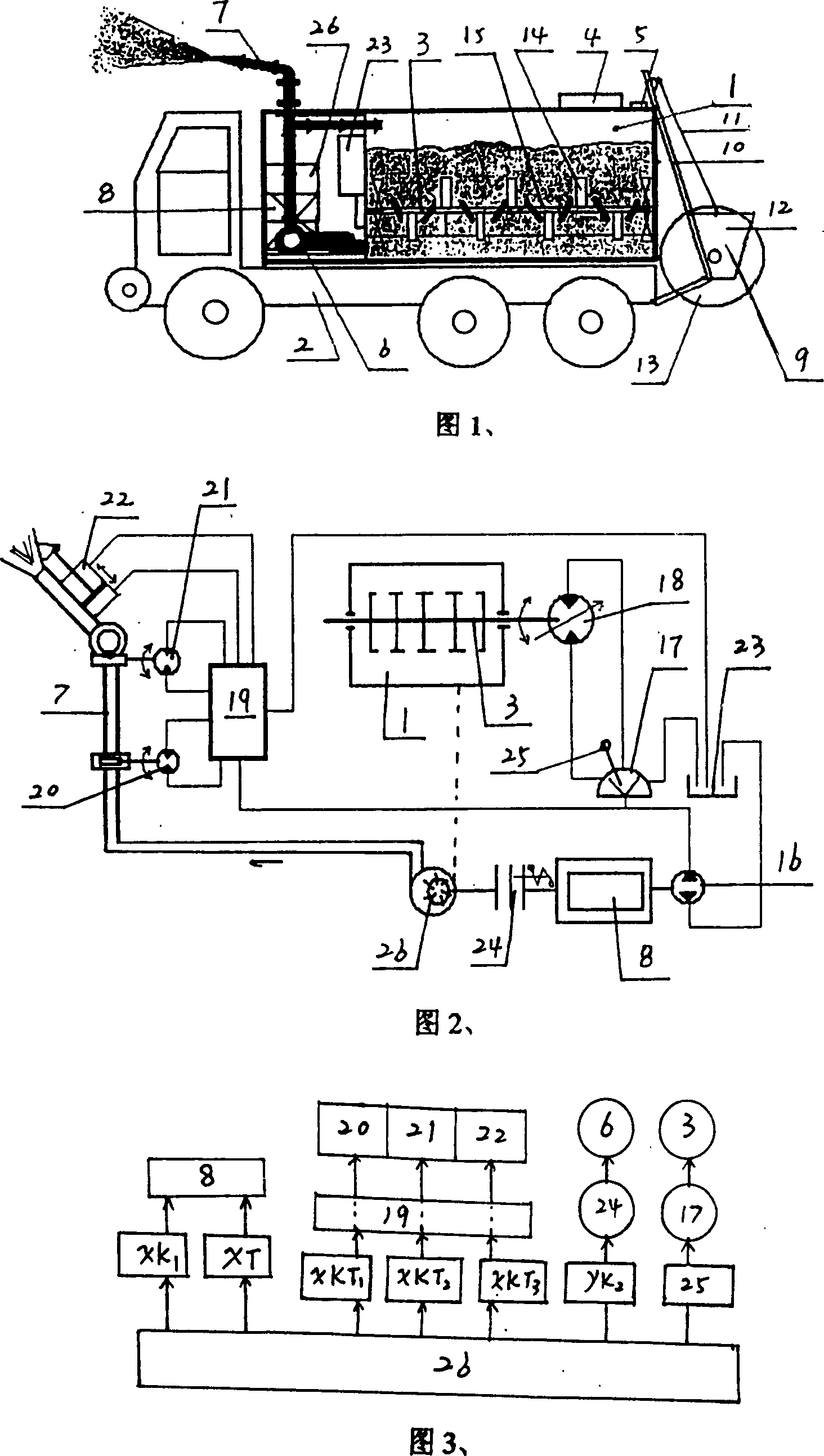

[0012] Further detailed description in conjunction with accompanying drawings; Figure 5 shows a water injection port;

[0013] As shown in Figure 1, the section of the water tank 1 is similar to an ellipse, and is equipped with a slide rail type material lifting device 9 matched with the feeding port 4. It has a slide rail 10, and a hopper 12 driven by a rope 11 is attached to the slide rail. 10, the pull rope 11 is driven by the turntable 13 driven by the car engine; in the horizontal shaft paddle agitator 3, the blades 14 mounted on the rotating shaft 15 are distributed symmetrically in dynamic balance along the axial and radial directions of the rotating shaft 15, And it must be ensured that the material can form a three-way circulating mixed flow. The so-called three-way refers to the axial, radial and rotary directions, so that it is suitable for variable-speed rotary mixing of materials in a non-horizontal state and an unstable state;

[0014] As shown in Figures 1 and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com