Rejection type economization magneto-electric relay

A relay and magnetoelectric technology, applied in the direction of non-polar relays, etc., can solve the problems of high power consumption, hysteresis loss, and complexity of the inductance coil, and achieve the effects of saving non-ferrous metal materials, less failures, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

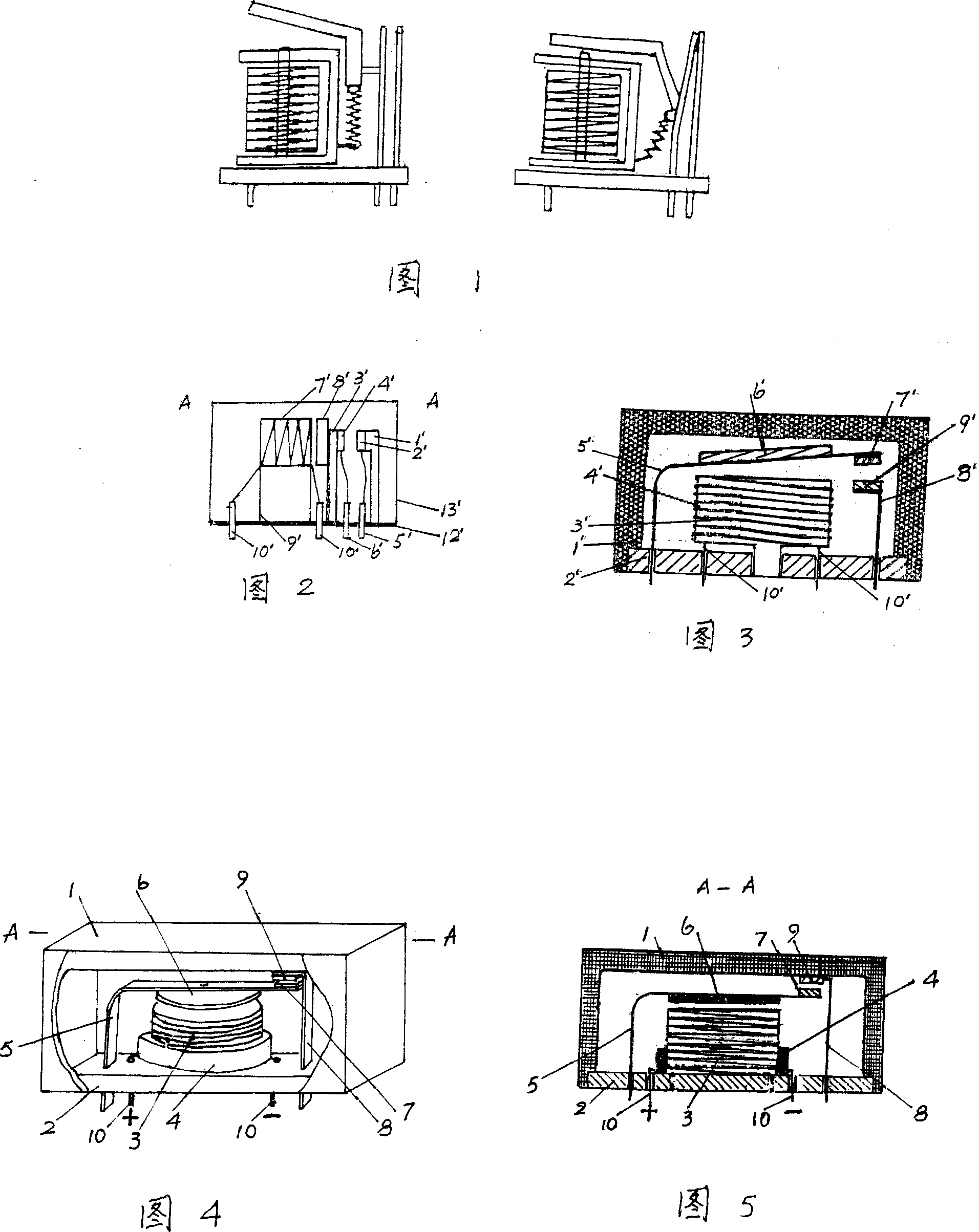

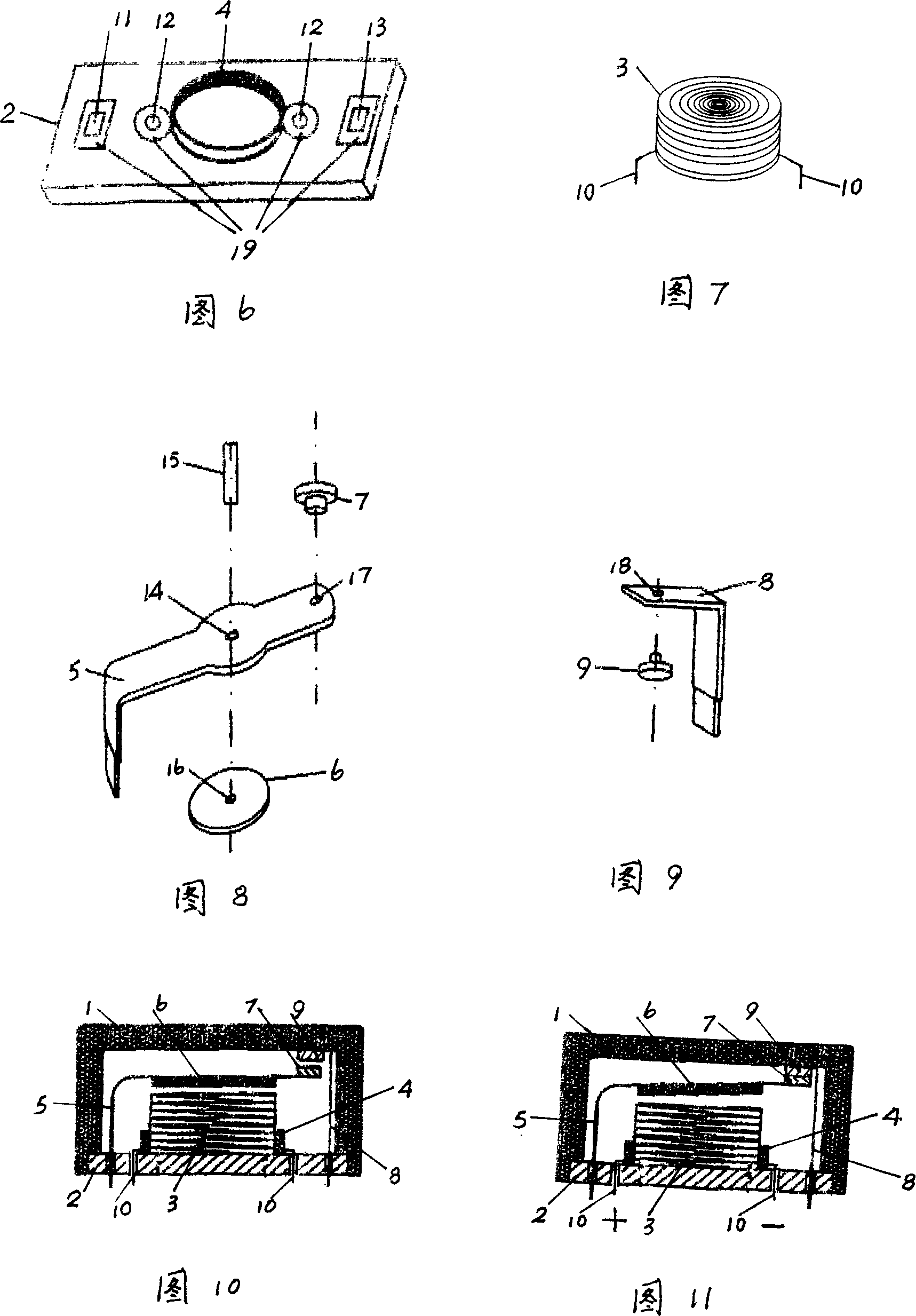

[0019] Embodiments of the present invention are described with reference to the accompanying drawings.

[0020] As shown in Figures 4 and 5, fasten the installation base (2) at the lower part of the insulating housing (1), and install the helical inductance coil (3) and helical inductance coil (3) in the inner cavity formed by the housing (1) and the base (2). Inductance coil positioning ring seat (4), moving reed (5), magnet (6), moving reed contact (7), static reed (8), static reed contact (9), spiral inductance coil Terminal post (10). There is no iron core in the helical inductance coil (3), the lower end of the helical inductance coil positioning ring seat (4) is fastened on the base (2), and the lower end of the helical inductance coil (3) is fastened on the helical inductance coil positioning In the ring seat (4), the helical inductance coil (3) cannot move along its axis or swing left and right. The moving reed (5) is in an inverted L shape, one side of the L shape i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com