Wave method of silicon controlled crystal brake pipe rectifier and its device

A technology of silicon thyristors and rectifiers, which is applied in the field of silicon-controlled thyristor rectifier wave generating methods and devices, can solve the problems of large ripple voltage on the rectifier bus and reduce the quality of rectifier output voltage, and achieve accurate SCR commutation operation, real-time Responsive, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is further elaborated below in conjunction with accompanying drawing and embodiment:

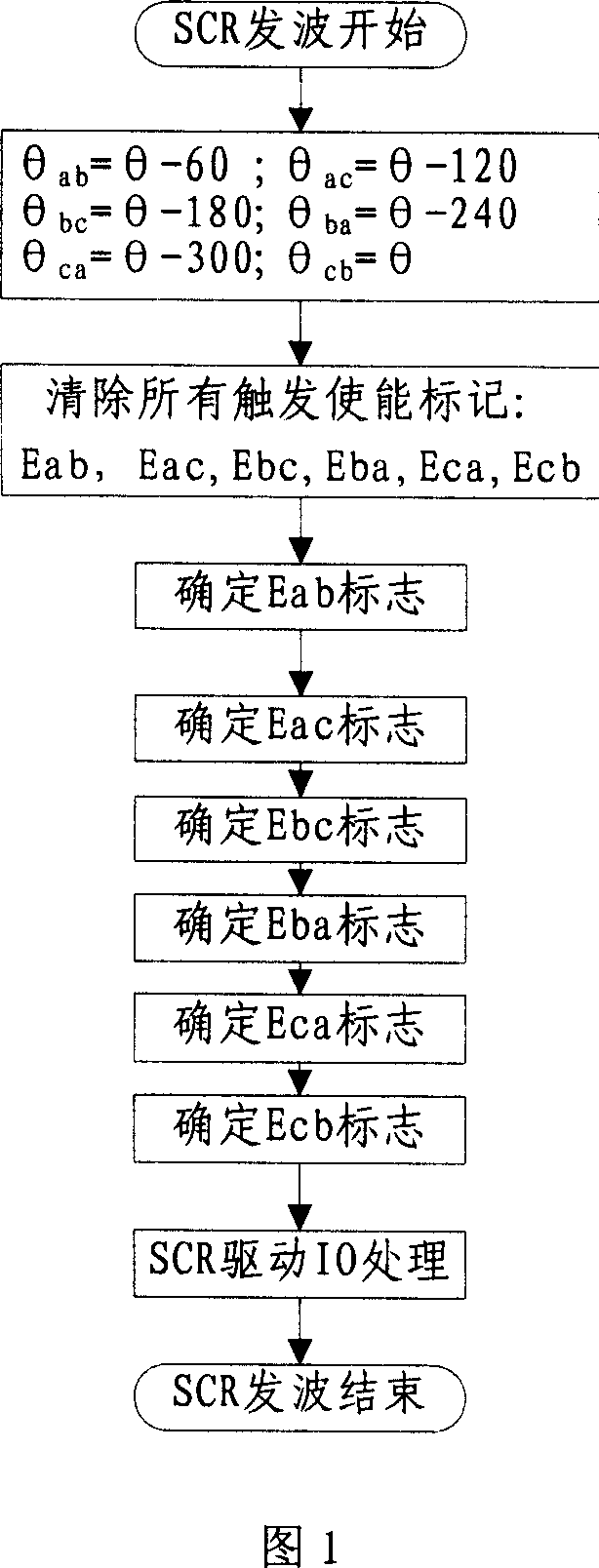

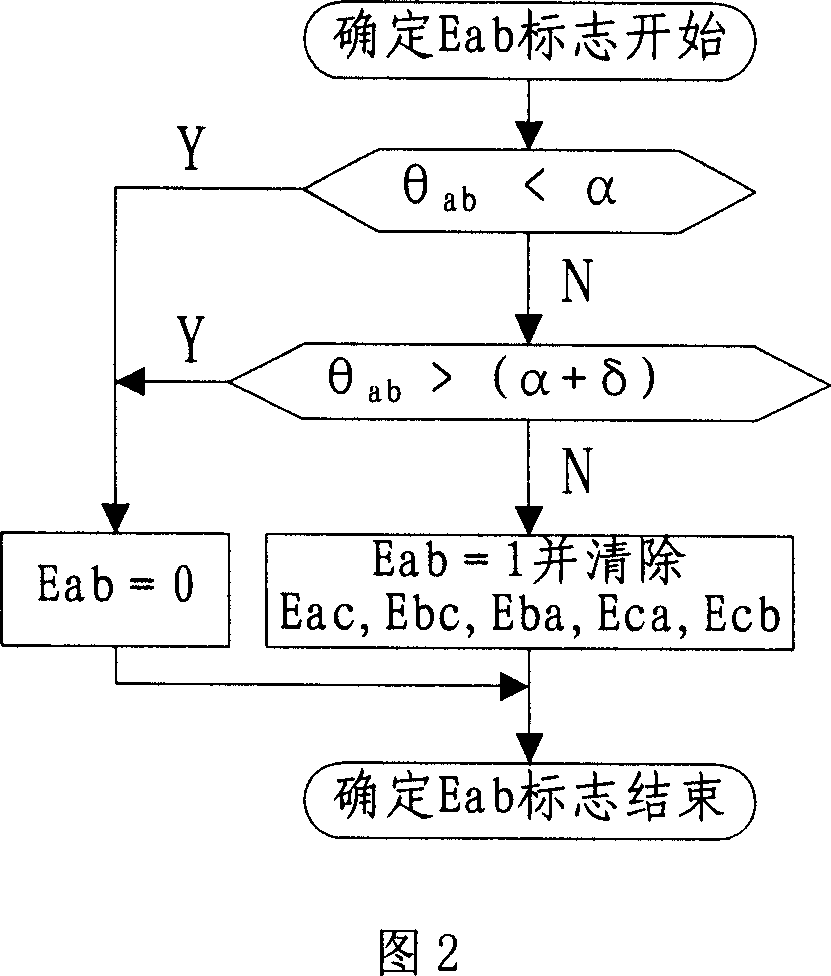

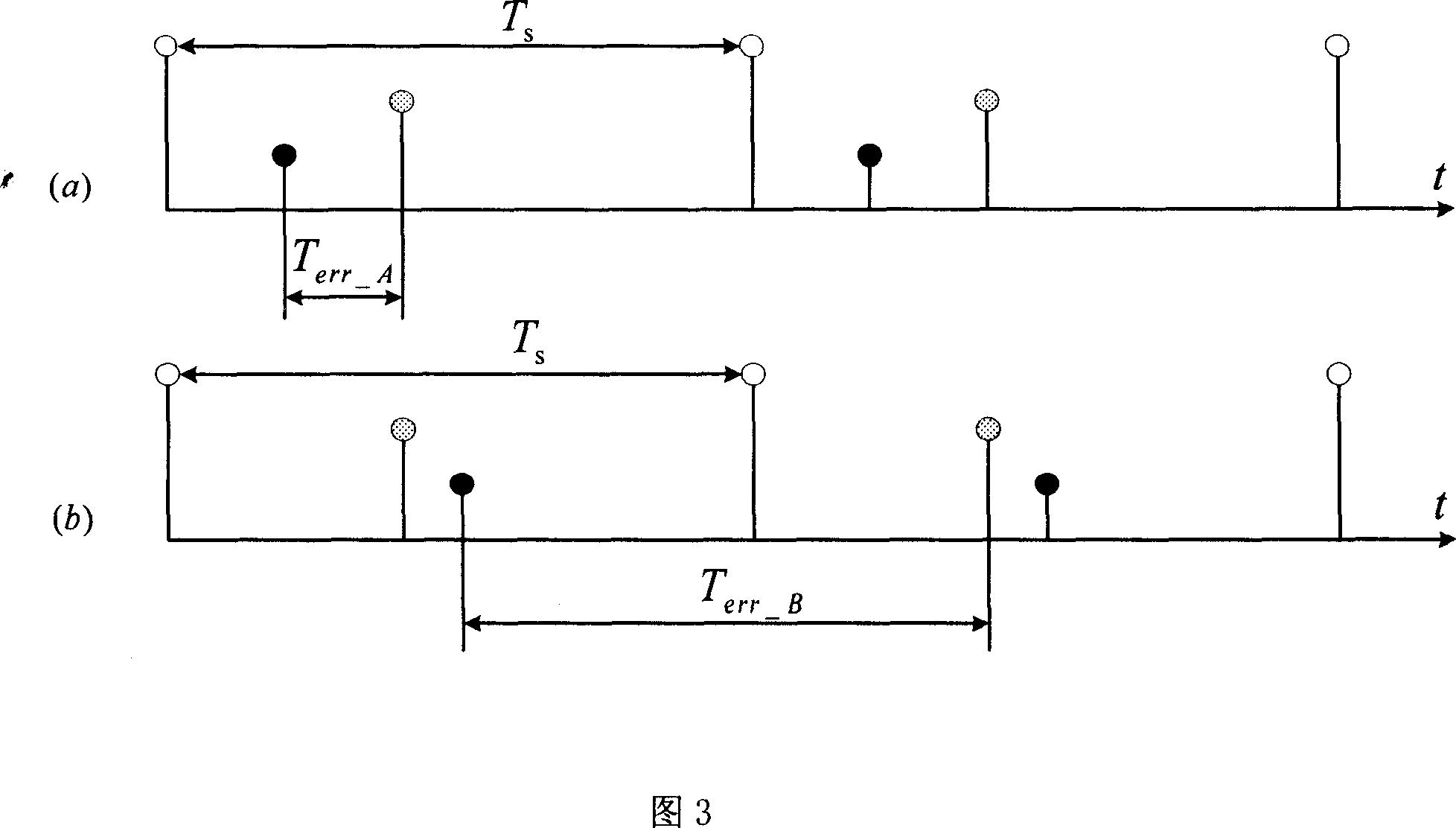

[0058] In order to solve the commutation error caused by conventional SCR wave transmission and realize accurate SCR commutation operation, the present invention adopts three methods, adding a high-priority interrupt mode in the timing interrupt, according to the phase and / or amplitude of the input voltage characteristics, as well as the firing angle of the thyristor, obtain the precise time of commutation of each thyristor in the rectifier, and preset the precise commutation time into the comparison unit of the timer, when the commutation time matches the timer A timer comparison interrupt occurs, and the SCR commutation operation is performed in the timer comparison interrupt service subroutine to realize accurate SCR commutation operation.

[0059] The specific implementation of method one is as follows:

[0060] Rewrite the previous SCR commutation condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com