Case material of domestic electrical equipment

A technology for home appliances and shells, which is applied in the field of shell plates for home appliances, which can solve the problems of high cost, cumbersome bonding work, and inability to guarantee the bonding force, and achieve the effect of low cost and omitting the coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

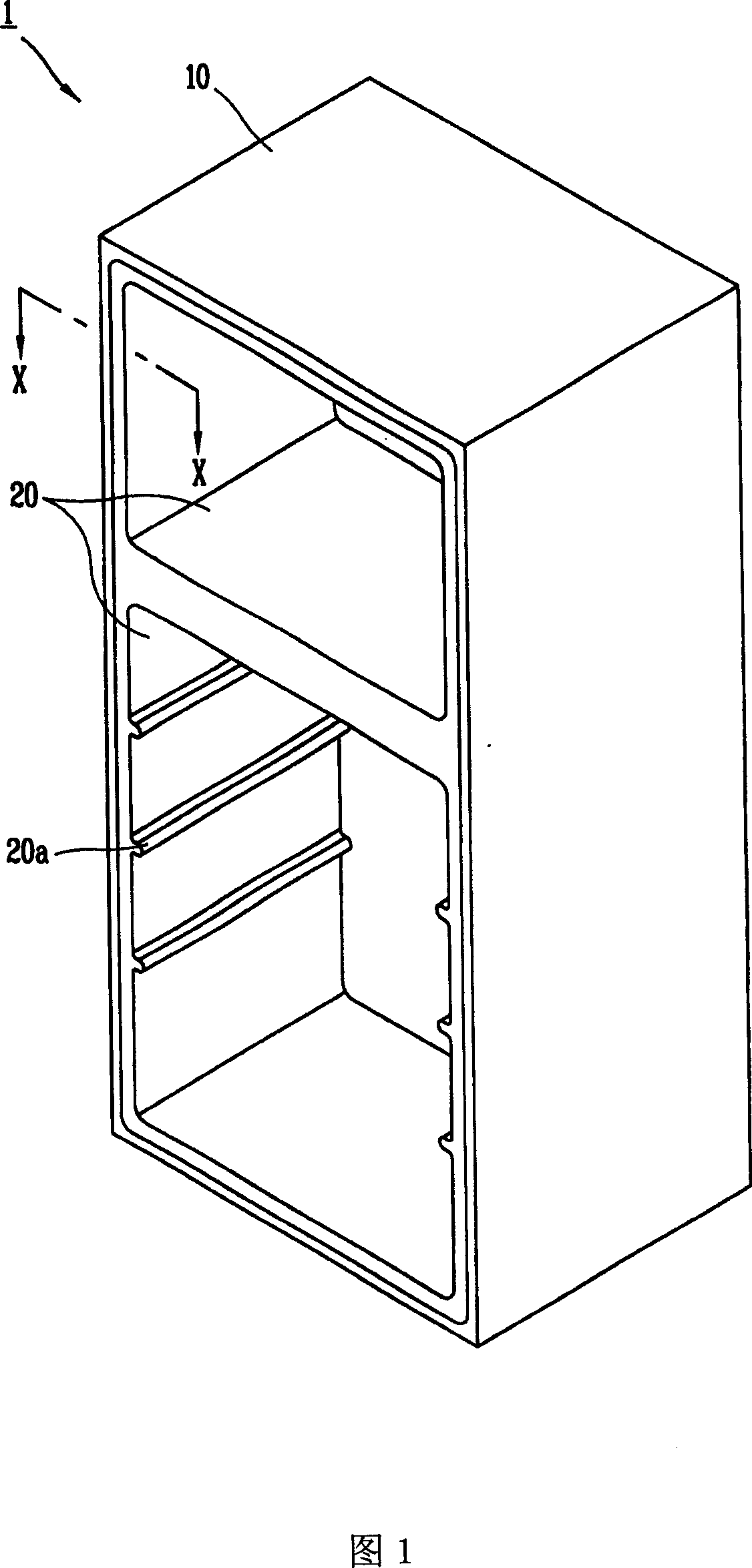

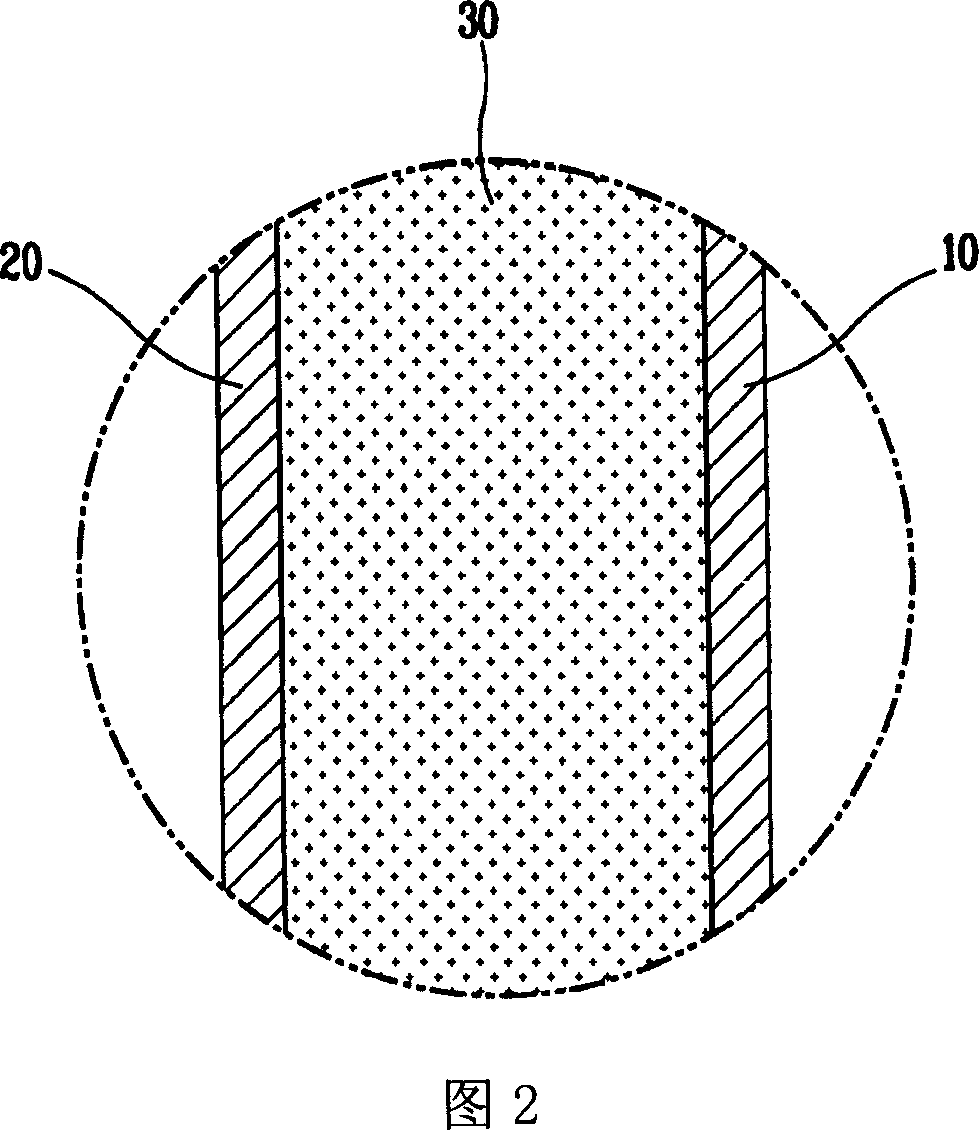

[0021] Hereinafter, an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

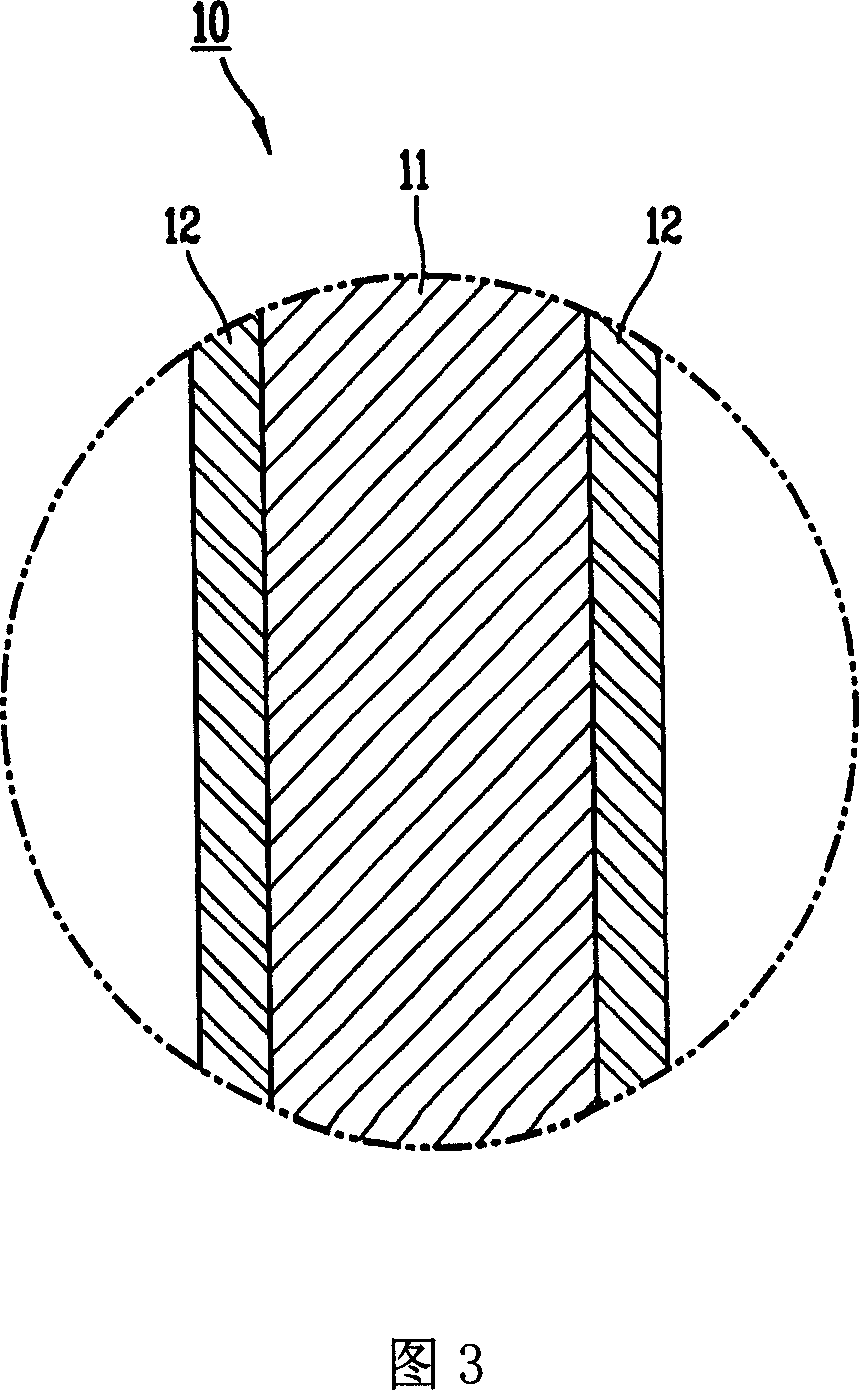

[0022] Fig. 4 is a schematic cross-sectional view of a shell plate according to an embodiment of the present invention. As shown in Fig. 4, the shell plates 10' of home appliances such as refrigerators and washing machines used in the embodiment of the present invention include: a relatively high-strength steel plate 11 that can protect the internal structure under external impact, and is formed on the outside of the home appliances. The outer surface of the steel plate 11, the surface treatment layer 12 that is galvanized, is formed on the inner surface of the steel plate 11 that is not exposed to the outside, and is coated with an adhesive ( Hotmelt) adhesive layer 100.

[0023] The surface treatment layer 12 can be a galvanized layer, or an acrylic or polyurethane series coating treatment layer.

[0024] The adhesive layer 100 can be made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com