Method for producing metal member, method for producing resin member, and method for producing exterior part

A manufacturing method and technology of metal components, applied in chemical instruments and methods, vehicle parts, transportation and packaging, etc., can solve the problems of large equipment and space, low productivity, etc., achieve excellent adhesion, and omit the effect of coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

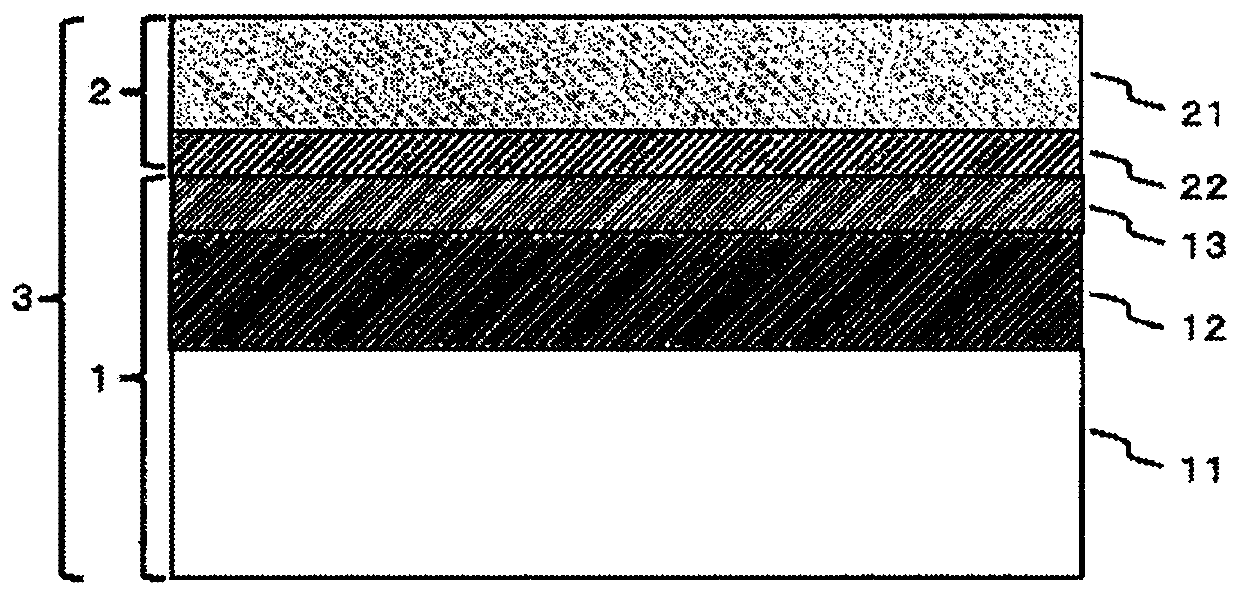

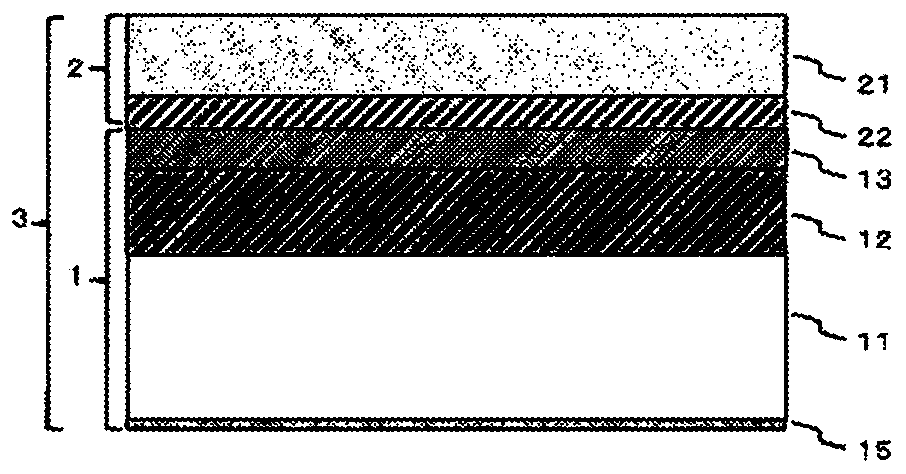

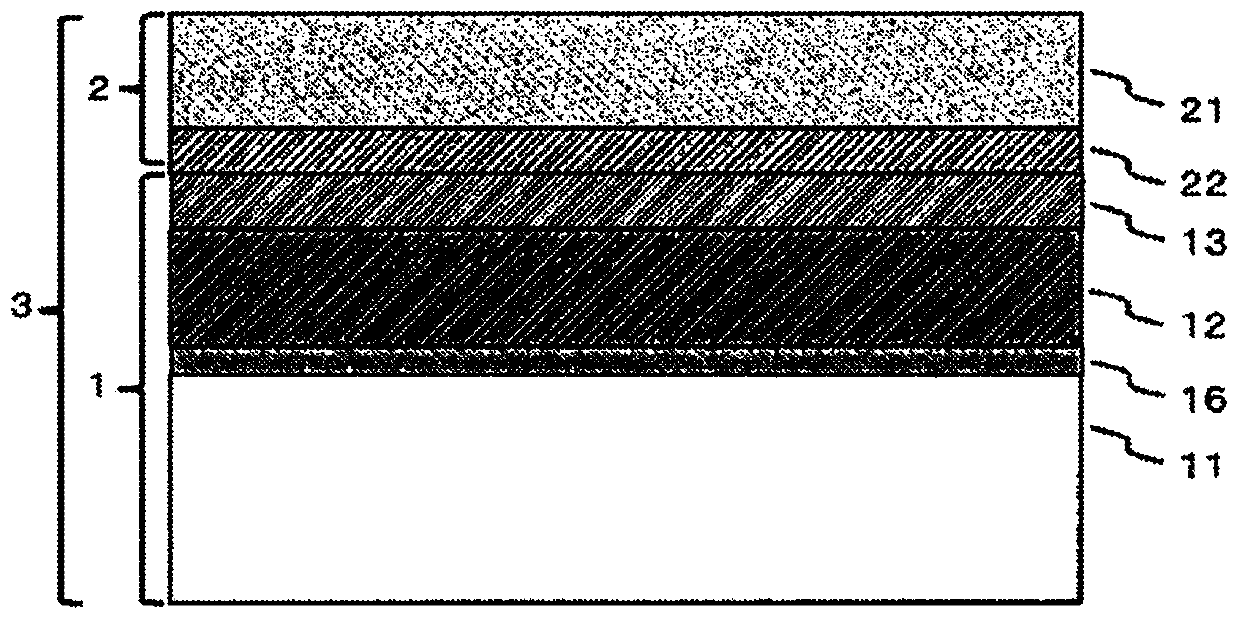

[0046] Hereinafter, the manufacturing method of the metal member of this invention, the manufacturing method of a resin member, and the manufacturing method of an exterior part are demonstrated concretely. First, the laminate of the present invention is composed of a paint substitute film and a protective film. Figure 1 to Figure 5 It is a partially enlarged cross-sectional view of a laminated body in which a coating substitute film and a protective film are laminated in the present invention, and the laminated body used in the present invention is not limited to Figure 1 to Figure 5 As for the laminated body shown, the laminated body which combined these can be used preferably, for example.

[0047] First, if figure 1 As shown, the coating replacement film 1 in one embodiment of this implementation is the same as the above-mentioned Image 6 Unlike the paint substitute film 1 obtained by the prior art described in , the thermoplastic resin film 11 of the paint substitute ...

example 2

[0097] Using the laminated body 3 having the coating substitute film 1 and the protective film 2 obtained above, the plated steel sheet JAC270F45 / 45 was laminated to produce a laminated steel sheet. Specifically, the laminated body 3 was uncoiled (that is, unwound), the plated steel plate was heated to 270° C. and guided, the lamination roll was kept at room temperature, and the coating of the laminated body 3 was applied to the resin 11B side of the film 1 side and The coated steel sheets are laminated by thermocompression bonding. The laminated steel sheets were immediately led to cooling water for cooling to obtain laminated steel sheets. The protective film 2 of the laminated steel sheet was peeled off, and the color difference was evaluated. Table 1 shows the results.

Embodiment 1

[0099] Cold forming was performed using the laminated steel sheet obtained above. Drawing was carried out at room temperature (25° C.) to a maximum of 20% in terms of metal formability, using a mold in which the door handle portion was assumed to be an outer panel shape of an automobile. A 10 mm grid was drawn on the film, and after confirming that the formed film had a degree of forming within 20% at the maximum, press forming of the laminated steel sheet was performed. Table 1 summarizes the results obtained by peeling off the protective film 2 after press molding and evaluating physical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com