Vapor/liquid separation apparatus for use in cracking hydrocarbon feedstock containing resid

A hydrocarbon raw material and equipment technology, applied in the field of vapor/liquid separation equipment, can solve the problems of removal and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

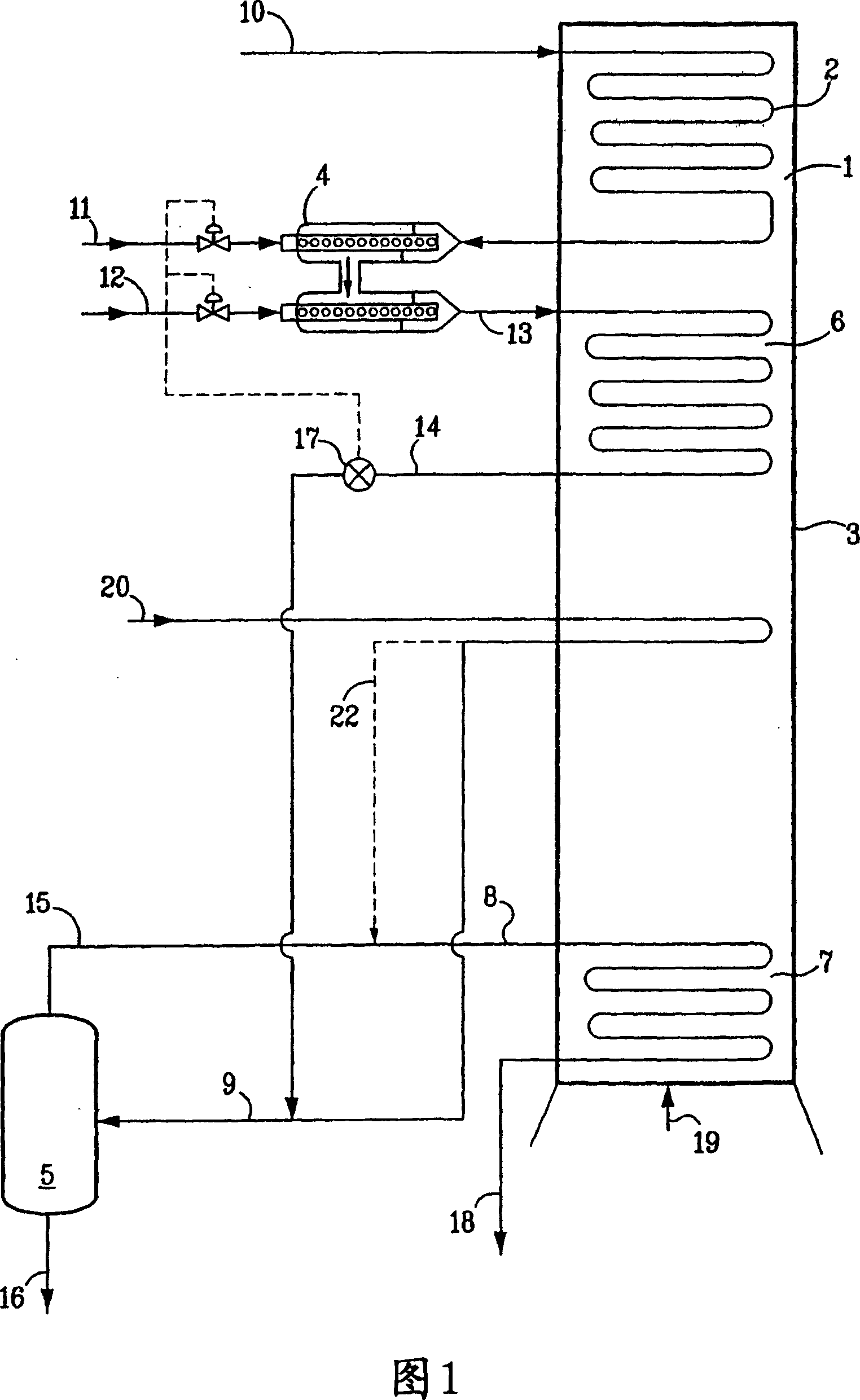

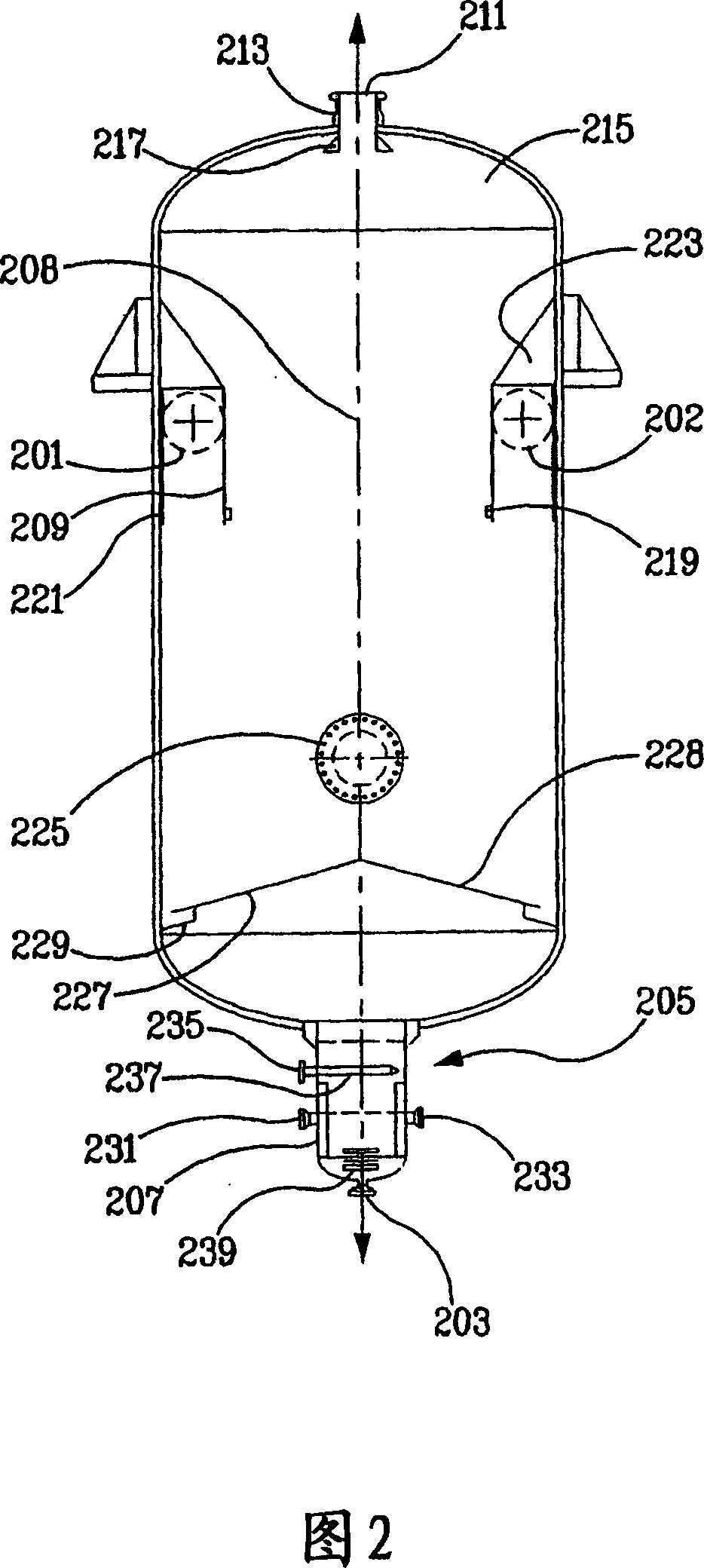

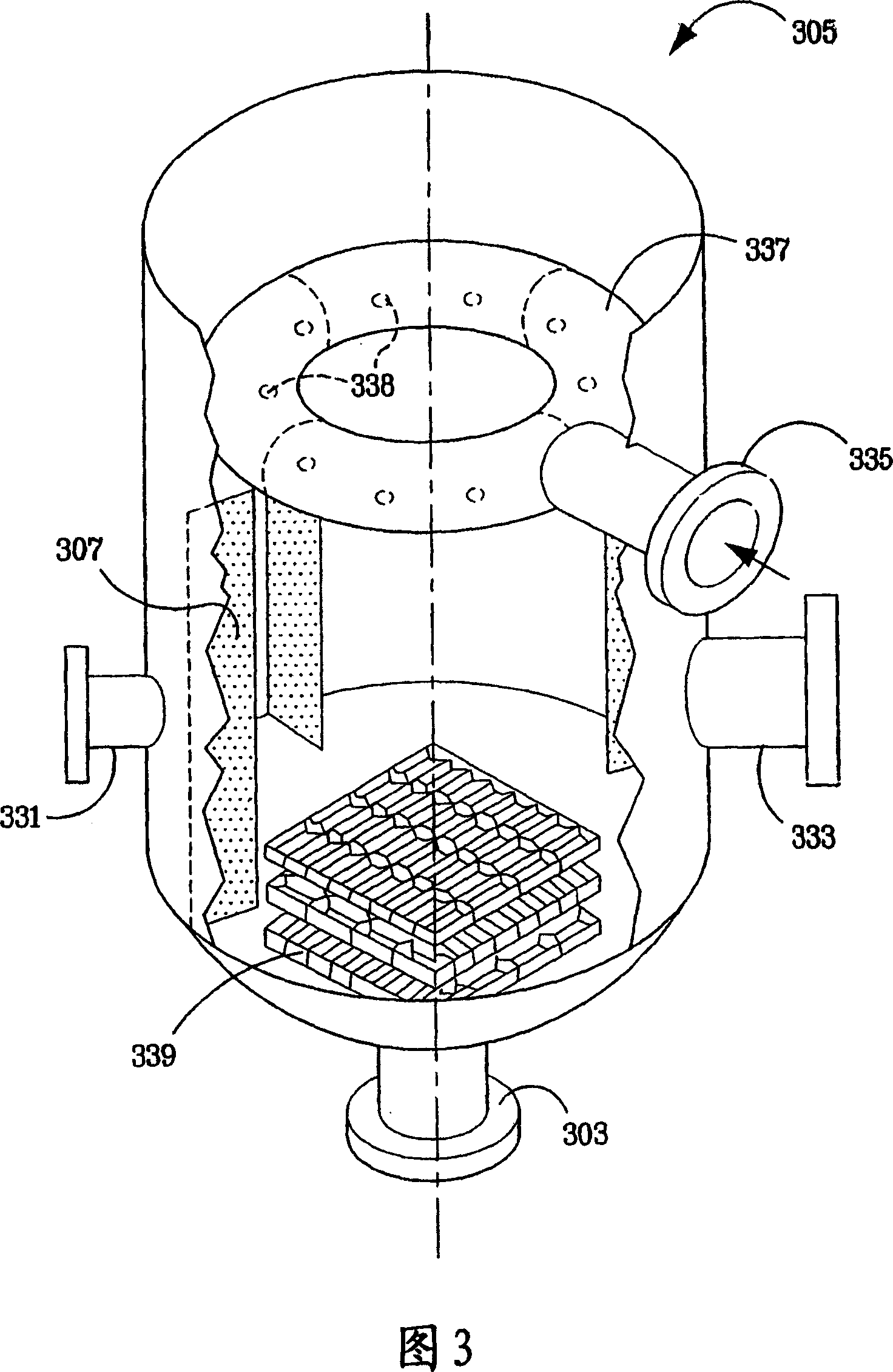

[0024] This invention relates to efficient vapor / liquid separation equipment for processing fluids of vapor / liquid mixtures of hydrocarbons and steam. The apparatus consists of a substantially cylindrical vertical drum or vessel having an upper cover section, a middle section comprising circular walls and a lower cover section, a tangential inlet for the introduction of a hydrocarbon / vapour mixture, an overhead vapor outlet, and a liquid bottom exit. The container also includes an annular structure located in the middle section, the annular structure comprising: (i) an annular top section extending from the circular wall and (ii) a coaxial inner vertical side wall into which the top section extends. The annular structure intercepts the upward passage of the vapor / liquid mixture along the circular wall beyond the top section, and the annular structure surrounds an open core having sufficient cross-sectional area to allow the vapor velocity to be low enough Avoid significant en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com