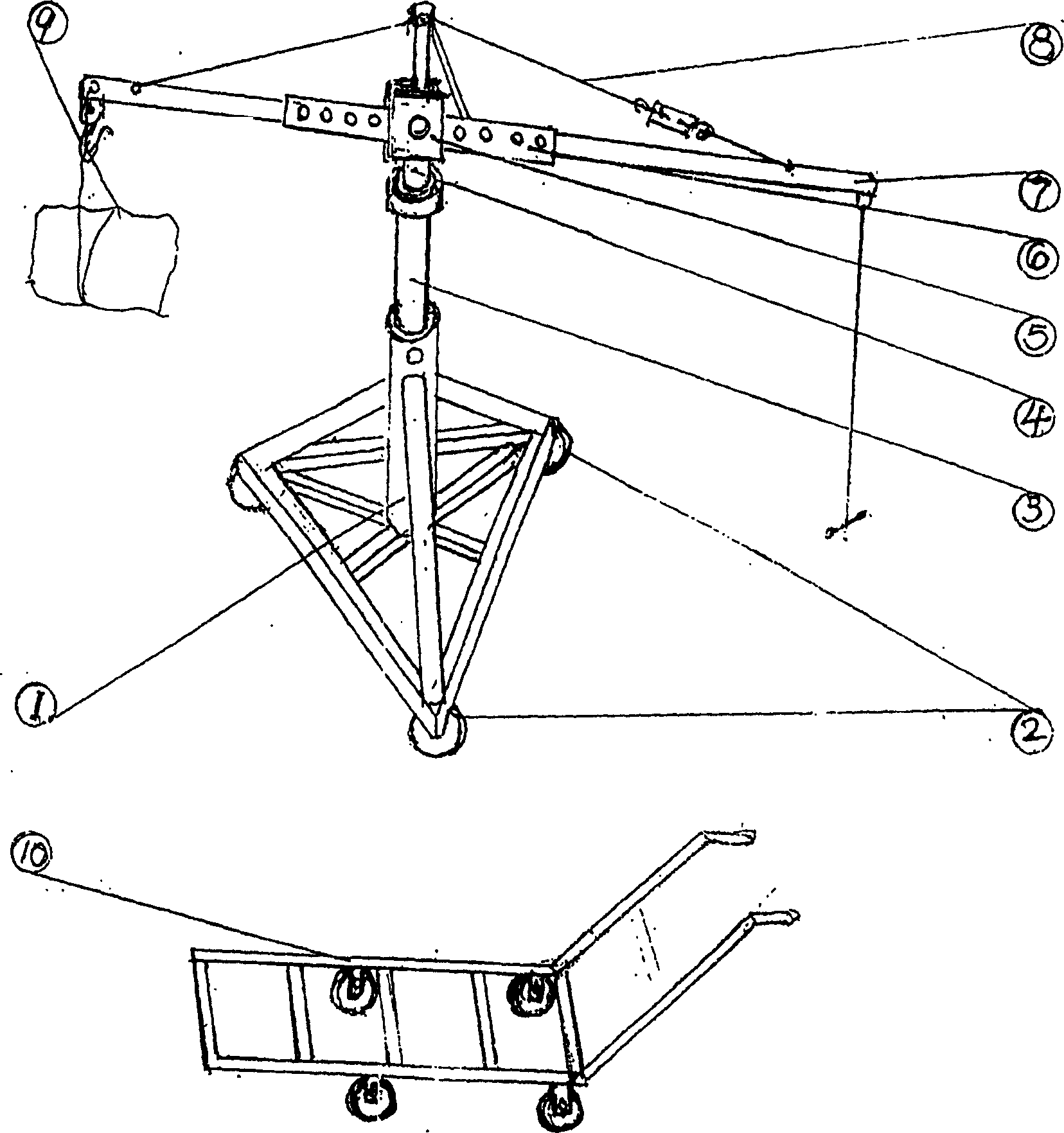

Manual type foodstuff loader

A set and auxiliary machinery technology, applied in cranes and other directions, can solve the problems of inconvenient movement, high cost, large volume, etc., and achieve the effects of convenient movement, simple operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing. The base ① is a cone-shaped seat frame composed of a vertical shaft sleeve and a tripod. There is a universal wheel ② under it, and holes at equal distances are drilled on the vertical shaft sleeve ③, which are set in the sleeve of the base ①. The rotating shaft ④ is set on the vertical shaft sleeve by the bearing, and the seat clip ⑤ is fixed on it, which can rotate horizontally. The T-shaped head is welded on the lever sleeve ⑥, which is combined with the rotating shaft and the seat clip ⑤. , can move up and down. The lever arm ⑦ is composed of two pieces, which are respectively inserted into the two ends of the lever sleeve and fixed by pins. Since the lever sleeve is drilled with equidistant holes, the length of the lever arm can be adjusted. The two ends of the lever arm are combined by wire drawing ⑧ through the top of the T-shaped head. The top of the lever is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com