Low level, heating power deaerator

A thermal deaeration and deaerator technology, applied in chemical instruments and methods, steam separation devices, liquid degassing, etc., can solve the problems of water pump cavitation, small pressure head, waste of energy and water resources, etc., to avoid steam Corrosion, improve utilization, promote the effect of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

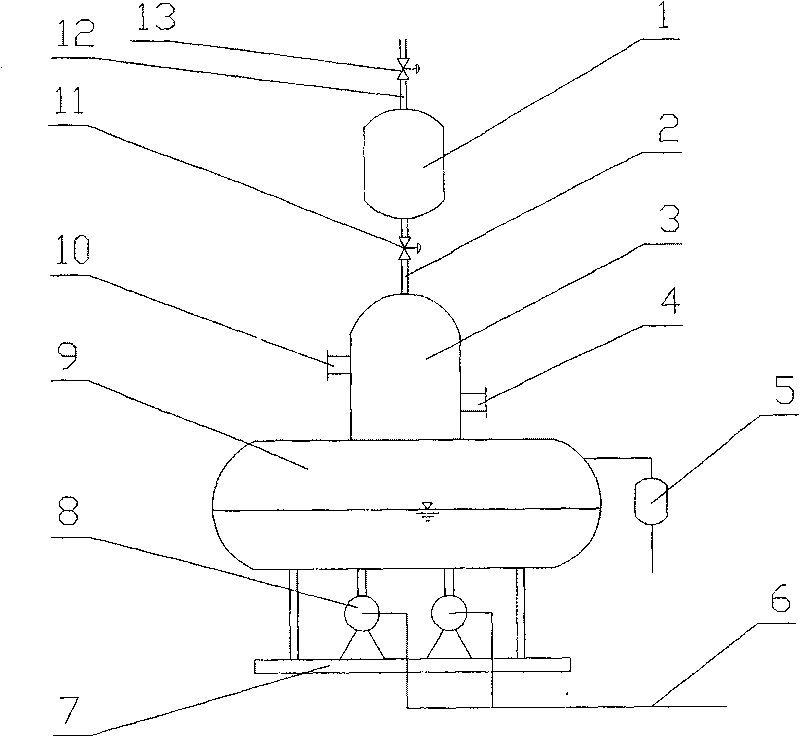

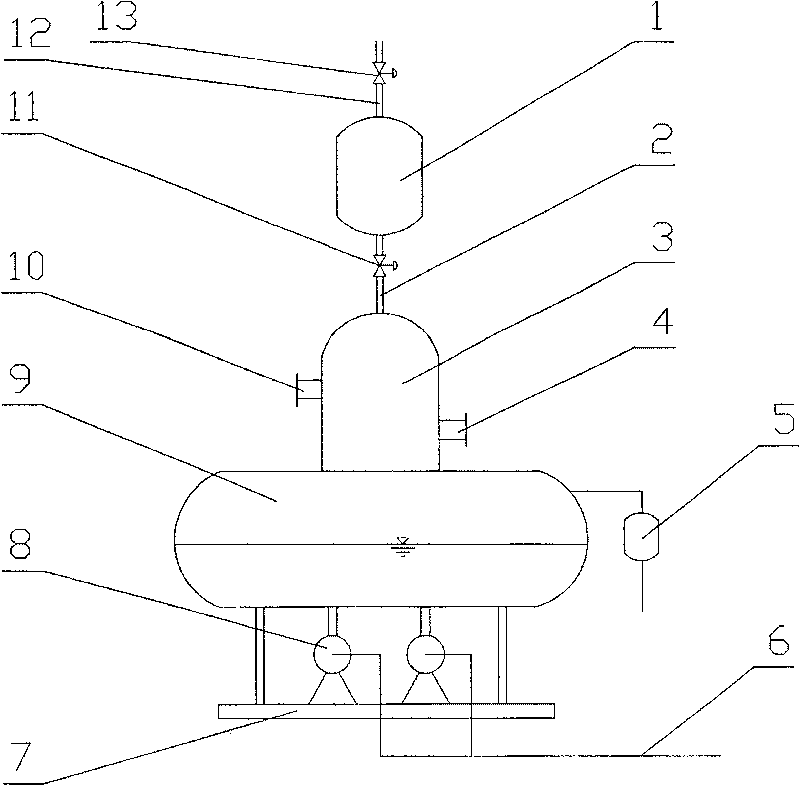

[0007] Referring to the accompanying drawings, a low-level thermal deaerator includes a deaerator body composed of a degassing tower 3 and a water tank 9. The degassing tower is provided with a steam inlet pipe 10, a water inlet pipe 4 and an exhaust pipe 2. The exhaust pipe is connected to the buffer tank 1.

[0008] The exhaust pipe is provided with a valve 11, which can be a normally open electric control valve. Under normal conditions, the steam in the degassing tower directly enters the buffer tank through its exhaust pipe, the exhaust valve of the buffer tank is closed, and the steam is not discharged outside, thus creating pressure in the buffer tank and the degassing tower. When the pressure reaches a certain value, close the exhaust pipe valve of the degassing tower, open the exhaust valve of the buffer tank to discharge the oxygen and non-condensable gas in the buffer tank, then close the exhaust valve of the buffer tank, and open the exhaust valve of the degassing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com