Circuit board supplying device, circuit board rolling device, circuit board processing system, circuit board supplying method and circuit board rolling method

A supply device, circuit board technology, applied in the direction of circuit, printed circuit, printed circuit manufacturing, etc., to achieve the effect of suppressing poor installation and suppressing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, best embodiments of the present invention will be described with reference to the drawings.

[0043] (implementation form 1)

[0044] (Composition of PCB handling system)

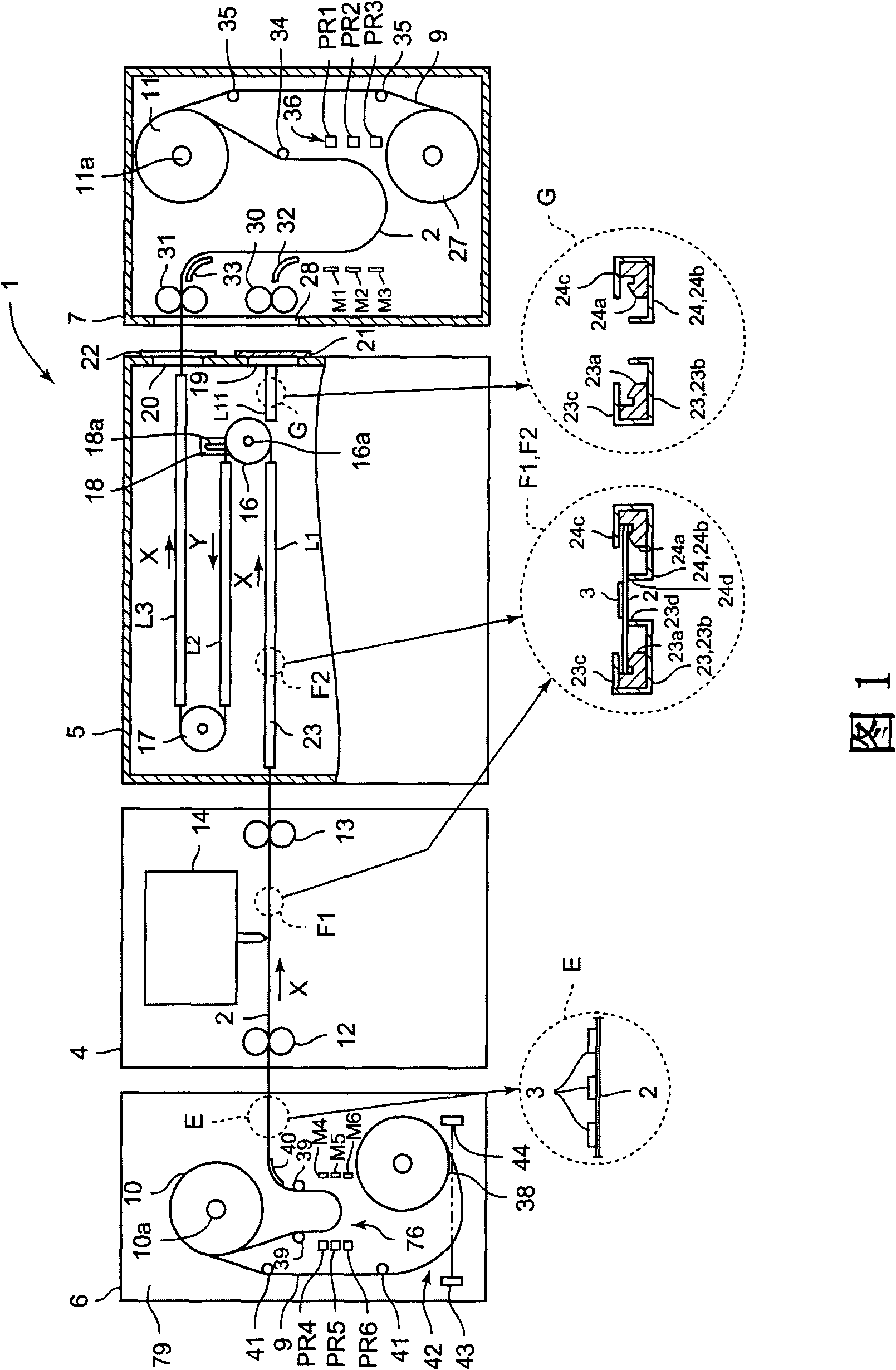

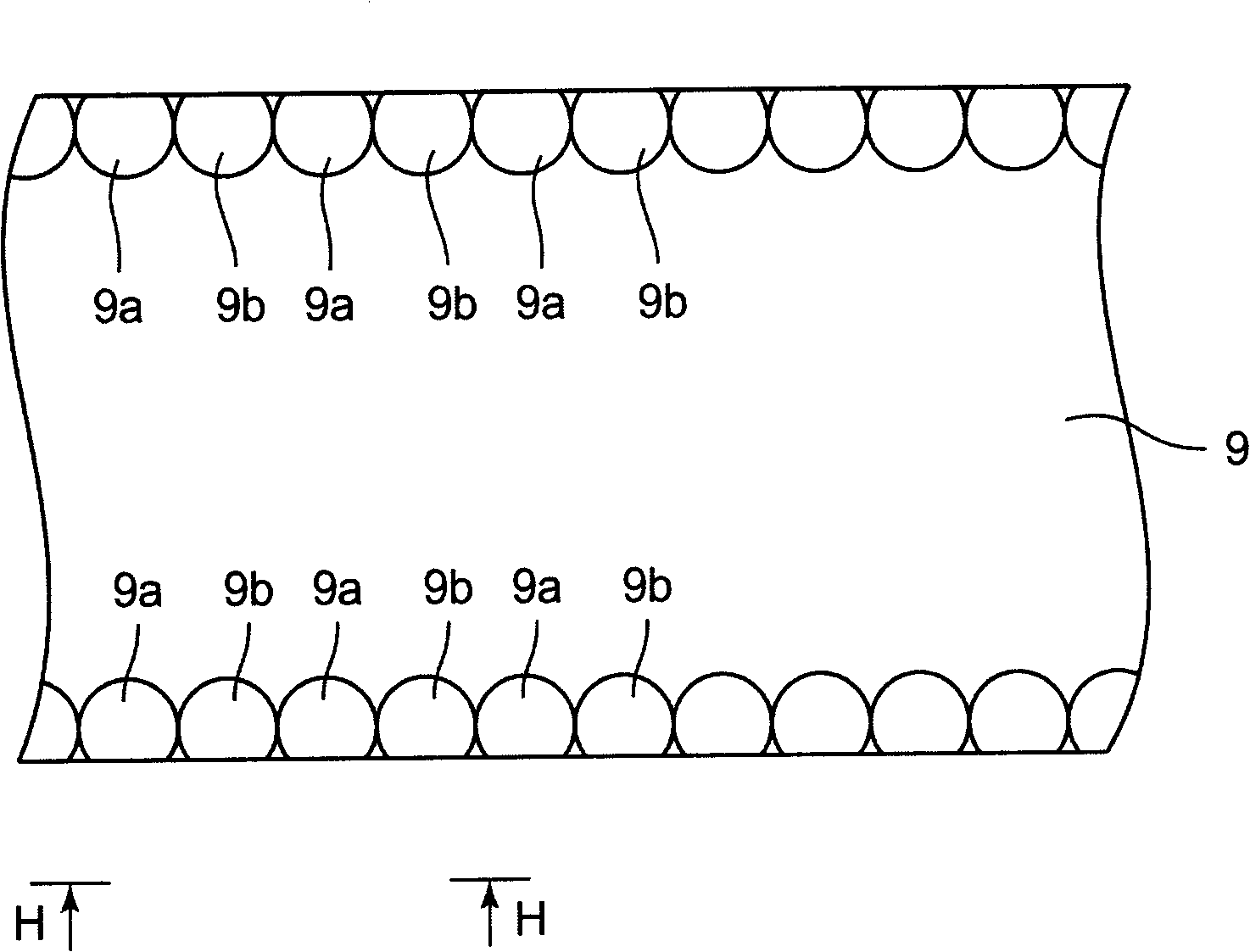

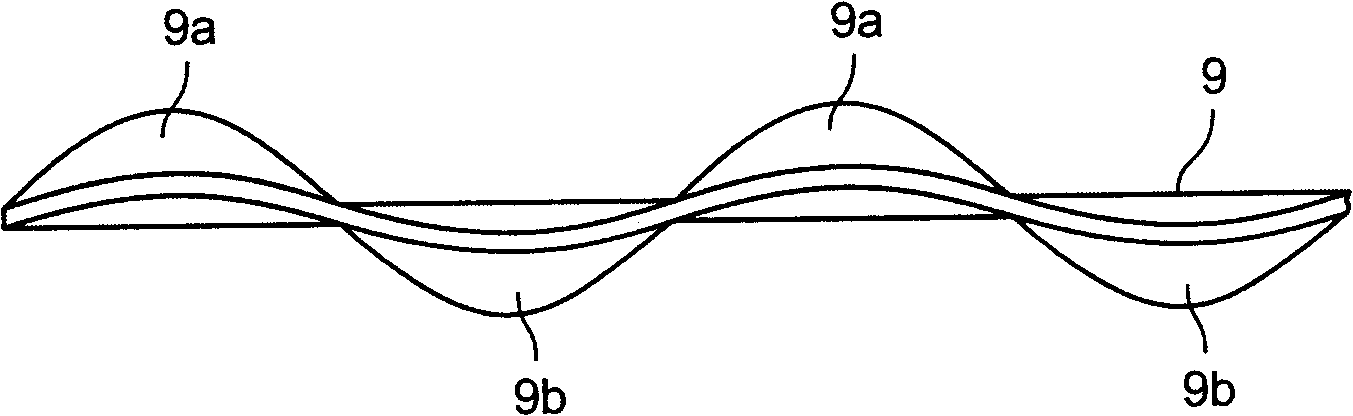

[0045] figure 1 It is a diagram showing the schematic configuration of the circuit board processing system 1 according to the first embodiment of the present invention. figure 2 yes means figure 1 A top view of liner 9 is shown. image 3 From figure 2 An enlarged side view showing the side of the spacer 9 enlarged in the H-H direction of FIG. Figure 4 yes figure 1 An explanatory diagram of controlling the winding of the circuit board 2 according to the sagging amount of the circuit board 2 in the circuit board winding device 7 shown. Figure 5 yes figure 1 The diagram showing the schematic configuration of the circuit board supply device 6 is shown. Figure 6 yes means figure 1 A side view showing the schematic configuration of the drive portion of the pad take-up reel 38 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com