Vehicular pushing and paving in-phase device for desert vegetation

A technology for vegetation and vehicles, applied in the field of dynamic synchronous push paving devices for desert vegetation vehicles, can solve the problems of uneven layer thickness, high manufacturing cost, high power consumption, etc., and achieve good synchronous running speed and speed , easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

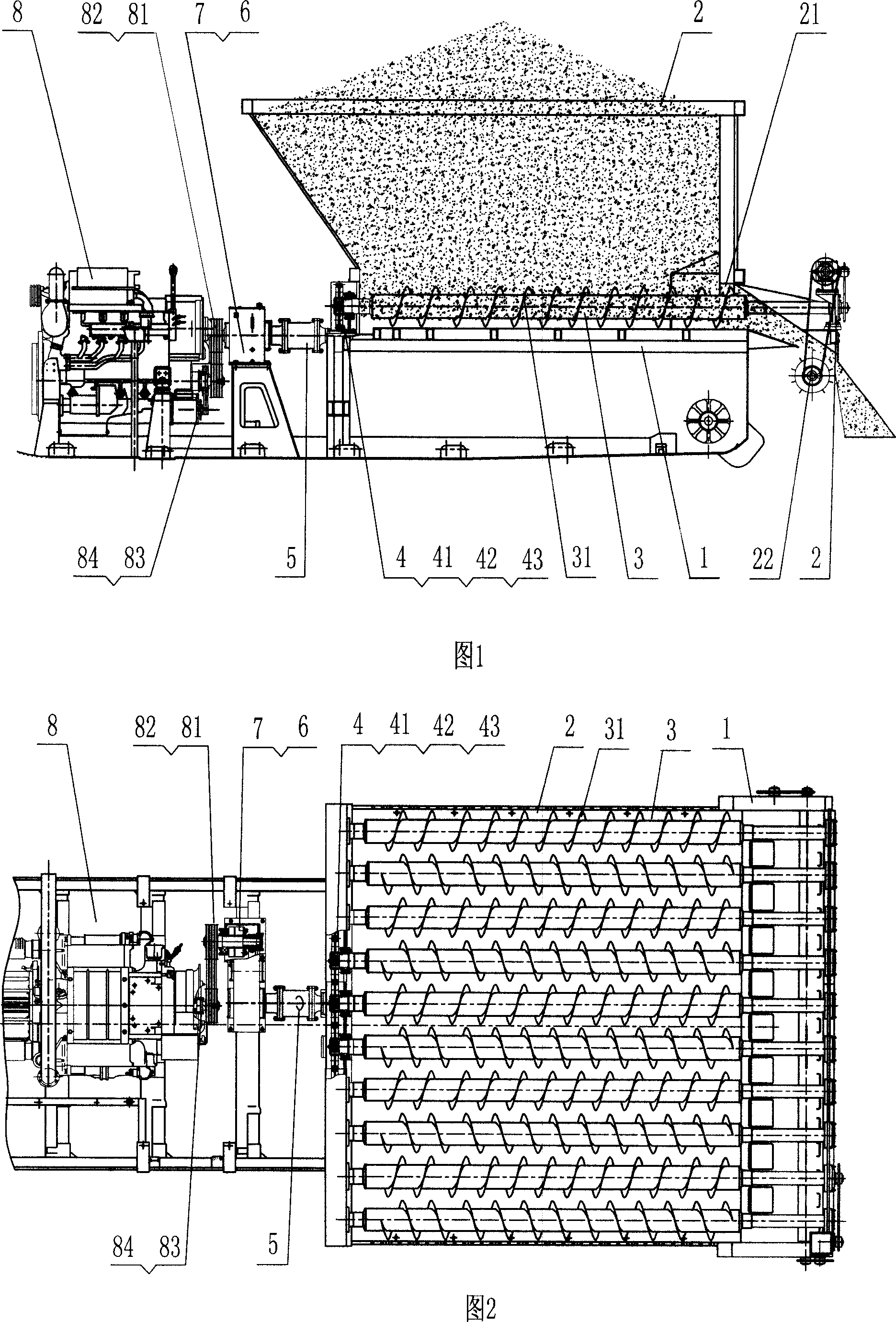

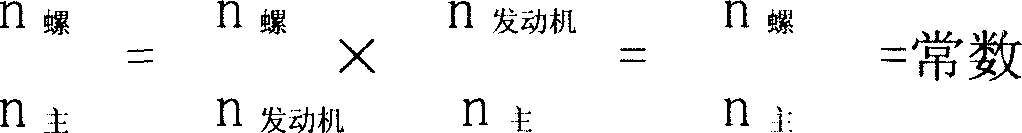

[0021] Referring to the accompanying drawings, a dynamic synchronous pushing and paving device for desert vegetation vehicles is provided with n screw shafts 3 and their screw blades 31 at the bottom of the hopper box 2. For example, the pushing width of each screw shaft 3 is b, and n screw shafts 3. The propulsion width is b×n, which is the realized paving width. In this embodiment, 5 pairs of 10 longitudinal screw shafts 3 and their helical blades 31 are arranged at the bottom of the hopper box 2, and the propulsion width b×10 can be realized. The screw shaft 3 is horizontally arranged and fixed on the car body bracket 1 through the front and rear bearing seats 32, and the screw blades 31 on the screw shaft 3 are designed to be left-handed and right-handed, and the left-handed and right-handed screw blades 31 are arranged alternately, The helical blades 31 of each adjacent two helical shafts 3 rotate in opposite directions and are arranged in pairs. A helical gear box 4 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com