Cylinder set for use in retraction mechanism

A telescopic mechanism and oil cylinder group technology, applied in concrete transportation, fluid pressure actuating devices, etc., can solve the problems of insufficient support strength, inconsistent telescopic strokes, and short telescopic length of the telescopic mechanism, so as to simplify the overall structure and hydraulic pipelines, Improve safety and service life, reduce the effect of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

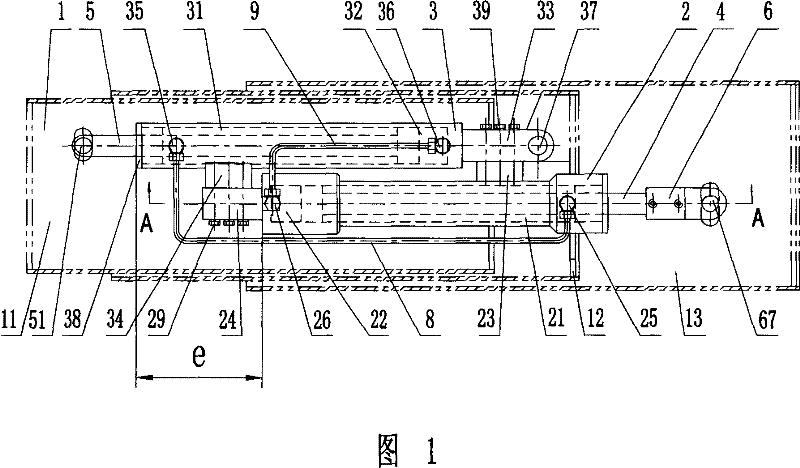

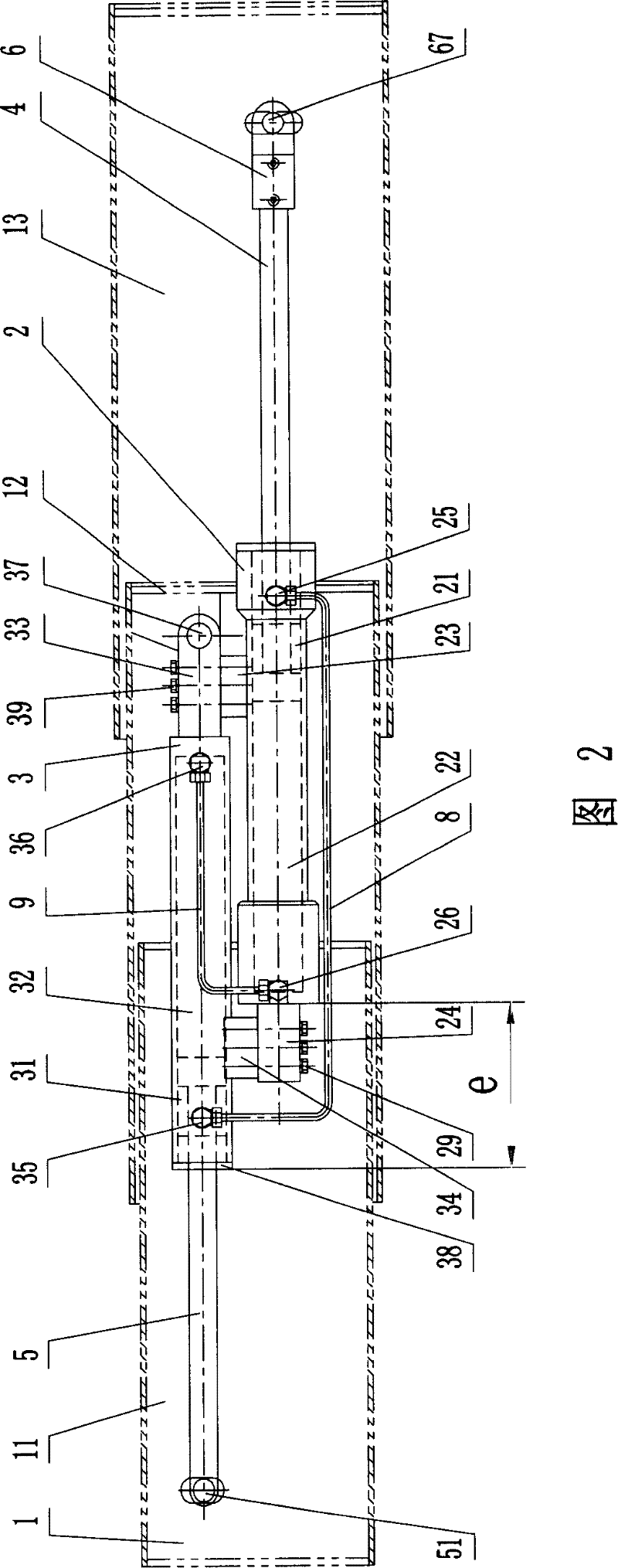

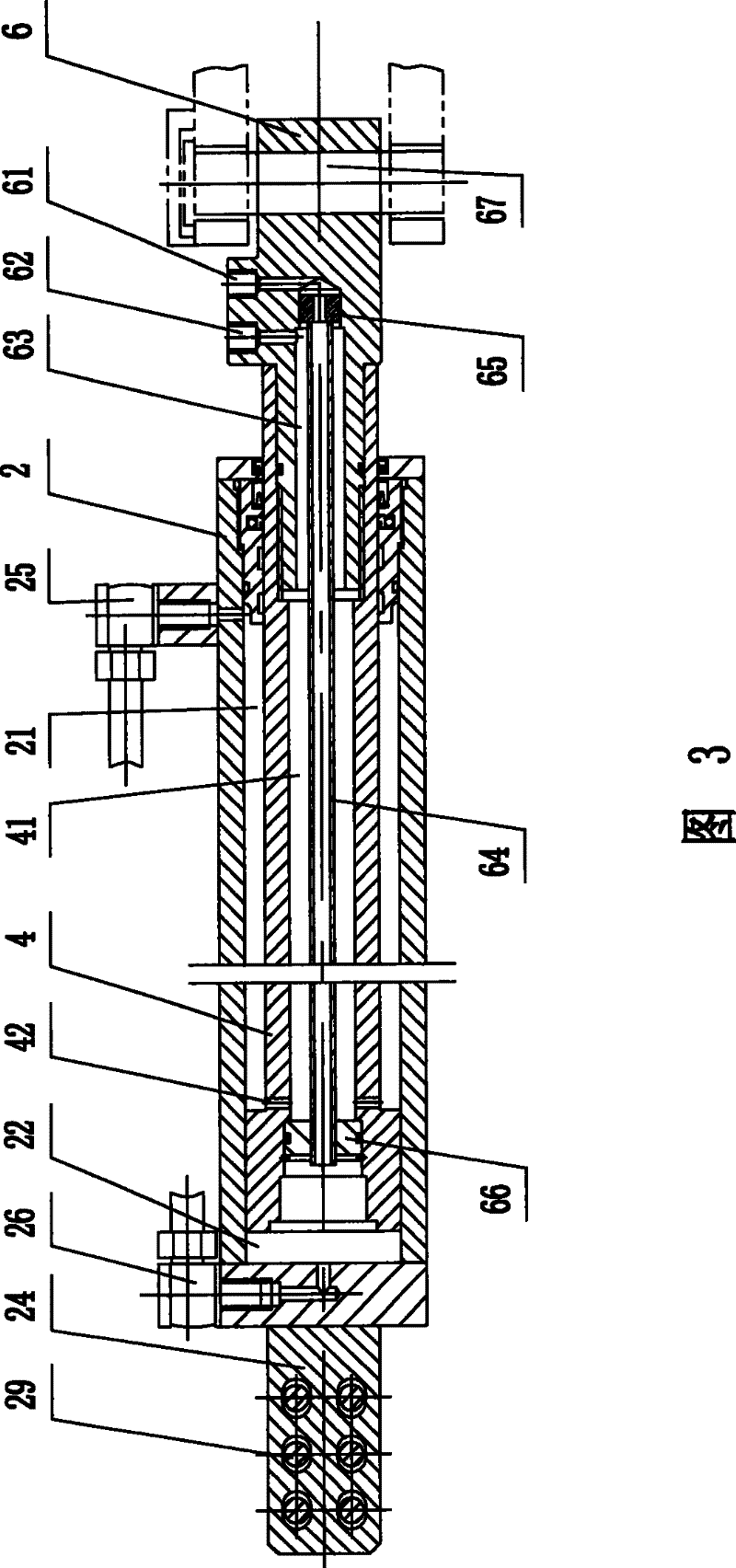

[0031] Such as figure 1 , figure 2 , image 3 As shown, the telescopic mechanism has a movable telescopic arm 11, an intermediate arm 12, and a fixed body 13. The oil cylinder group for the telescopic mechanism includes a first oil cylinder body 2 and a second oil cylinder body 3 installed on the telescopic mechanism 1, and the first oil cylinder The body 2 is provided with a first piston rod 4, the second cylinder body 3 is provided with a second piston rod 5, one end of the first piston rod 4 is located in the first cylinder body 2, and the other end is equipped with a piston rod head 6 , the rod chamber 21 and the rodless chamber 22 of the first oil cylinder body 2 communicate with the rod chamber 31 and the rodless chamber 32 of the second oil cylinder body 3 respectively, and the cylinder bodies are rigidly connected by connecting seats, and the two oil cylinder bodies are reversed Arrangement; the first cylinder block 2 is provided with a first cylinder block connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com