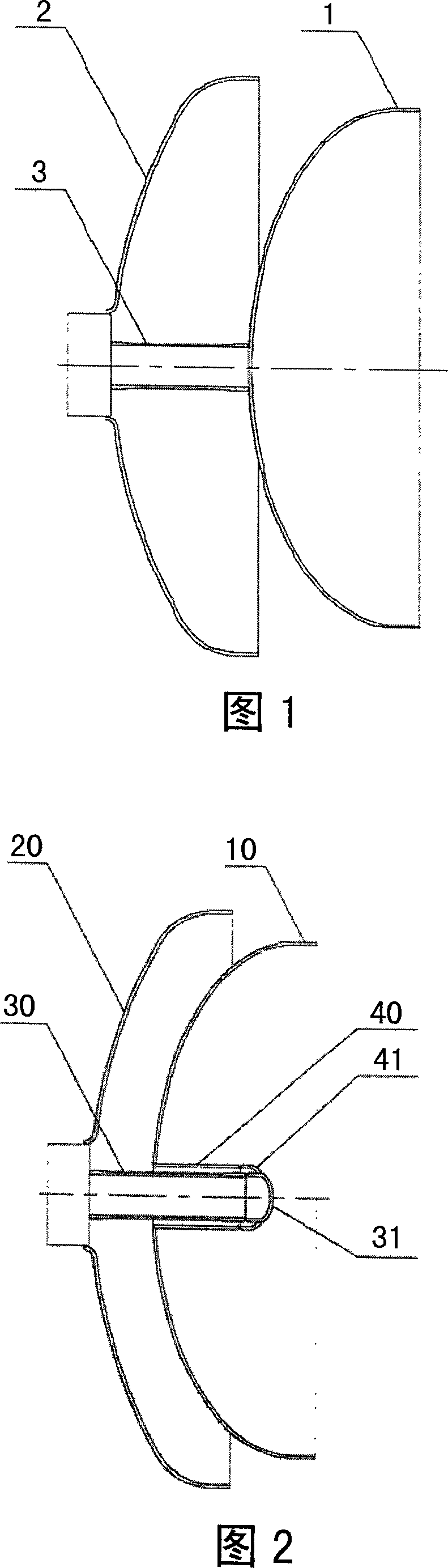

Internal bladder supporting structure for low temperature thermal-insulating gas cylinder

A support structure and low-temperature insulation technology, applied in the field of support structures, can solve the problems of low support strength, unfavorable liquid transportation efficiency, large spacing, etc., and achieve the effects of reducing heat transfer, improving transportation efficiency, and increasing support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] The front end of the 450-liter liquefied natural gas (LNG) vehicle gas cylinder adopts this support structure, which can reduce heat transfer, increase strength, and ensure the excellent performance and service life of the product.

example 2

[0028] The upper neck tube of the 200-liter vertical low-temperature insulated gas cylinder adopts this support structure, which can greatly optimize the daily evaporation rate index of the gas cylinder under the premise of ensuring strength. Of course, in order to install a liquid level gauge, etc., holes need to be opened on the cap of the small tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com