Testing method for sensor with dustproof, dedusting and explosion protection frunction, product and application of the same

A detection method and sensor technology, applied in the direction of instruments, analysis materials, etc., to achieve the effect of convenient and rapid replacement, guarantee of life safety, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

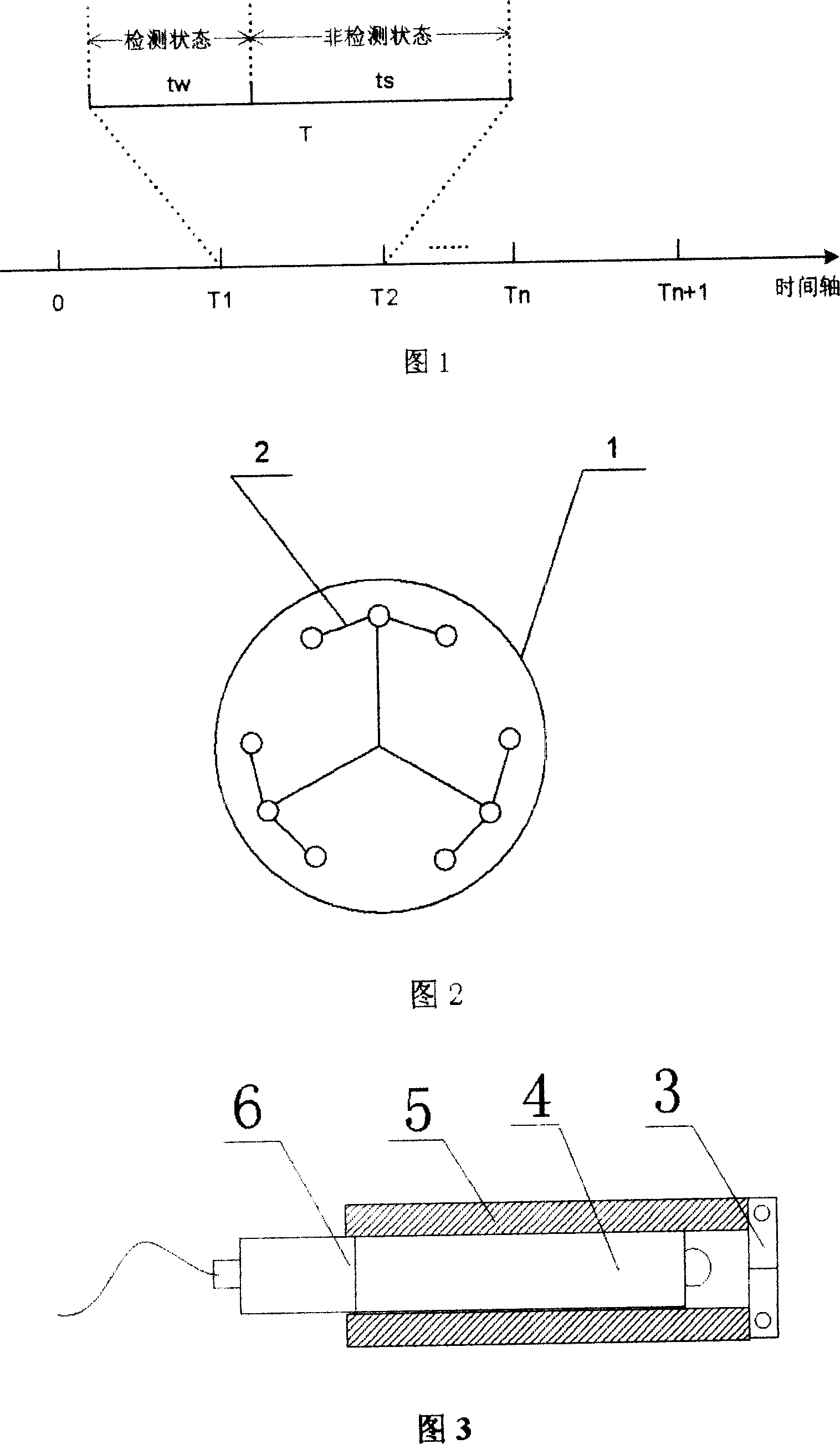

[0017] The dynamic and time-discrete monitoring form shown in Figure 1 is adopted: 0 o'clock on the time axis is the moment when the sensor is installed and starts to work. The time length of the detection cycle of the sensor is T, and each detection cycle can be divided into a detection state and a non-detection state, and their time lengths are tw and ts respectively. The sensors work in this cyclical fashion. The sensor itself and the sensor probe are two relatively independent parts, and the connection between the base inside the sensor and the sensor probe is a plug-in connection. The base to connect the sensor is a male plug and the sensor probe is a female jack. The inside of the female socket of the new sensor probe is filled with carbon dioxide or other inert gas, and the socket is sealed by a breakable film to prevent the inert gas from leaking. The inert gas can ensure that the new sensor probe is inserted into the sensor base, isolating sparks or electric sparks ...

Embodiment 2

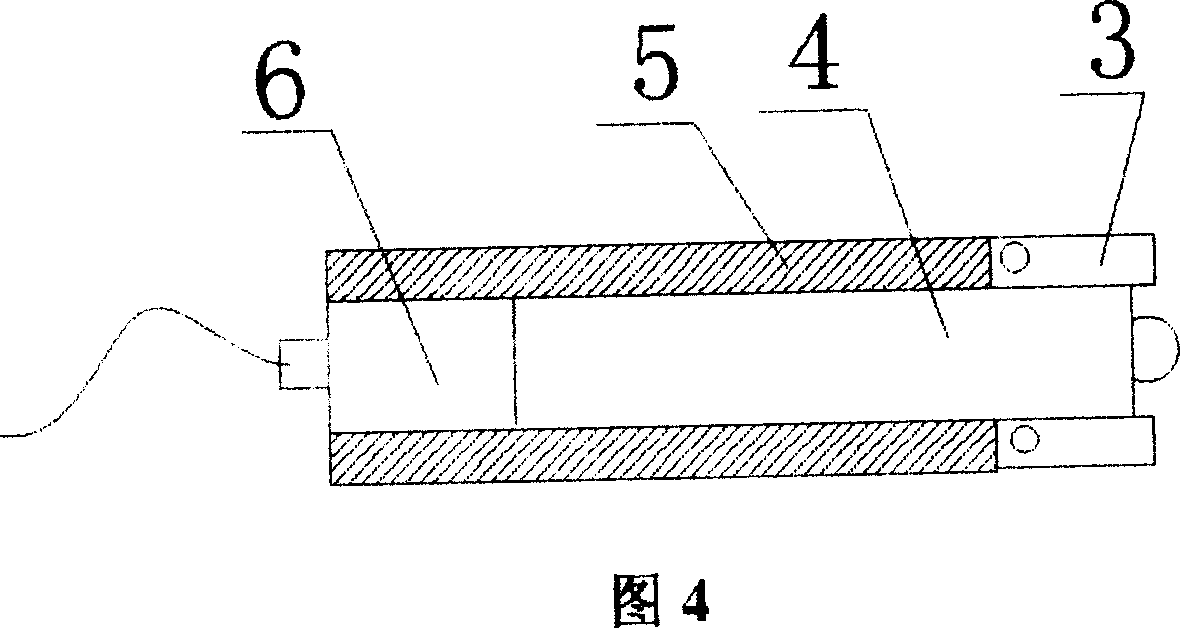

[0019] In high-dust and high-risk industrial and mining sites, such as tunnels in coal mines, if ordinary gas monitoring sensors are used, the detection holes of the sensors will be quickly blocked by falling dust, thus losing the monitoring function. Therefore, where a gas monitoring system needs to be installed, multiple new dust-proof, dust-removing and explosion-proof gas monitoring sensors will be installed. These new gas monitoring sensors can establish a data communication network through a wired or wireless transmission system, and transmit the collected information to the monitoring center server through the data communication network. The new sensor will sample and detect the environment in accordance with a predetermined cycle. After the sampling and detection is completed, the sensor probe will retract into the sensor and wait for the start of the next detection cycle. The specific process is as follows: when the sensor enters the detection cycle, the sliding cover...

Embodiment 3

[0021] In some high-dust environments, this dust-proof and dust-removing sensor is installed independently. The sensor will work according to the pre-established detection cycle. When the detection cycle of the sensor starts, the sliding cover is automatically opened to expose the small hole through which the sensor probe protrudes out of the sensor to detect the medium. After the detection is completed, the sensor probe retracts into the sensor, the slide cover is closed, and the sensor waits for the next detection cycle. During a detection cycle, the extension and retraction of the sensor probe will pass through the brush installed around the small hole. The dust accumulated on the surface of the sensor probe in the process of sampling and detection will be brushed away by the relative mechanical movement between the sensor probe and the brush, which can ensure the cleanliness of the sensor surface, thus ensuring the long-term normal operation of the sensor. When the senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com