Circuit breaker

A circuit breaker and circuit technology, applied in the direction of circuit breaker components, etc., can solve the problems of prolonging the breaking time, unable to break the circuit, and unable to break the arc with all the arc suppression plates 11, and achieve the effect of improving the current limiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

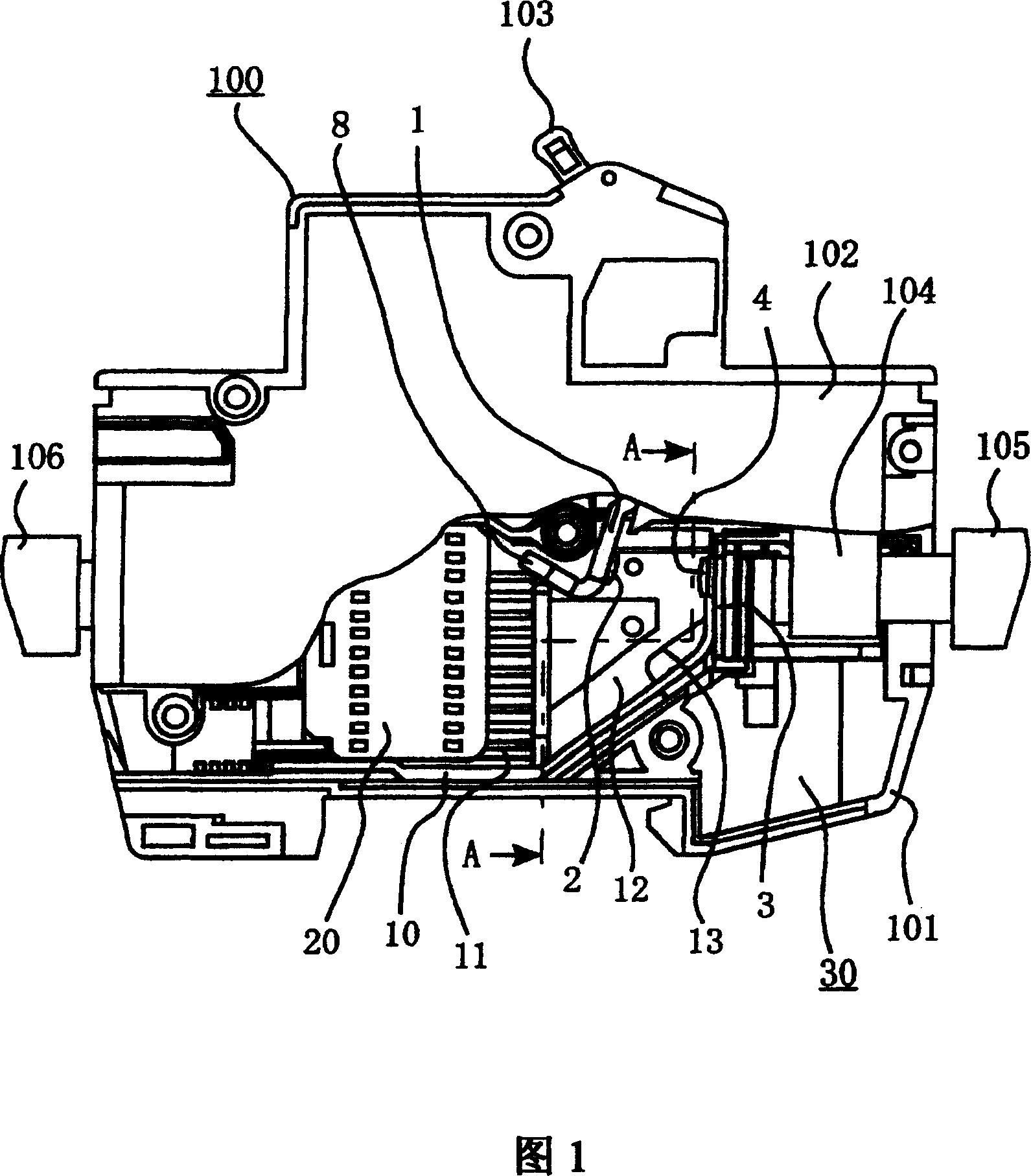

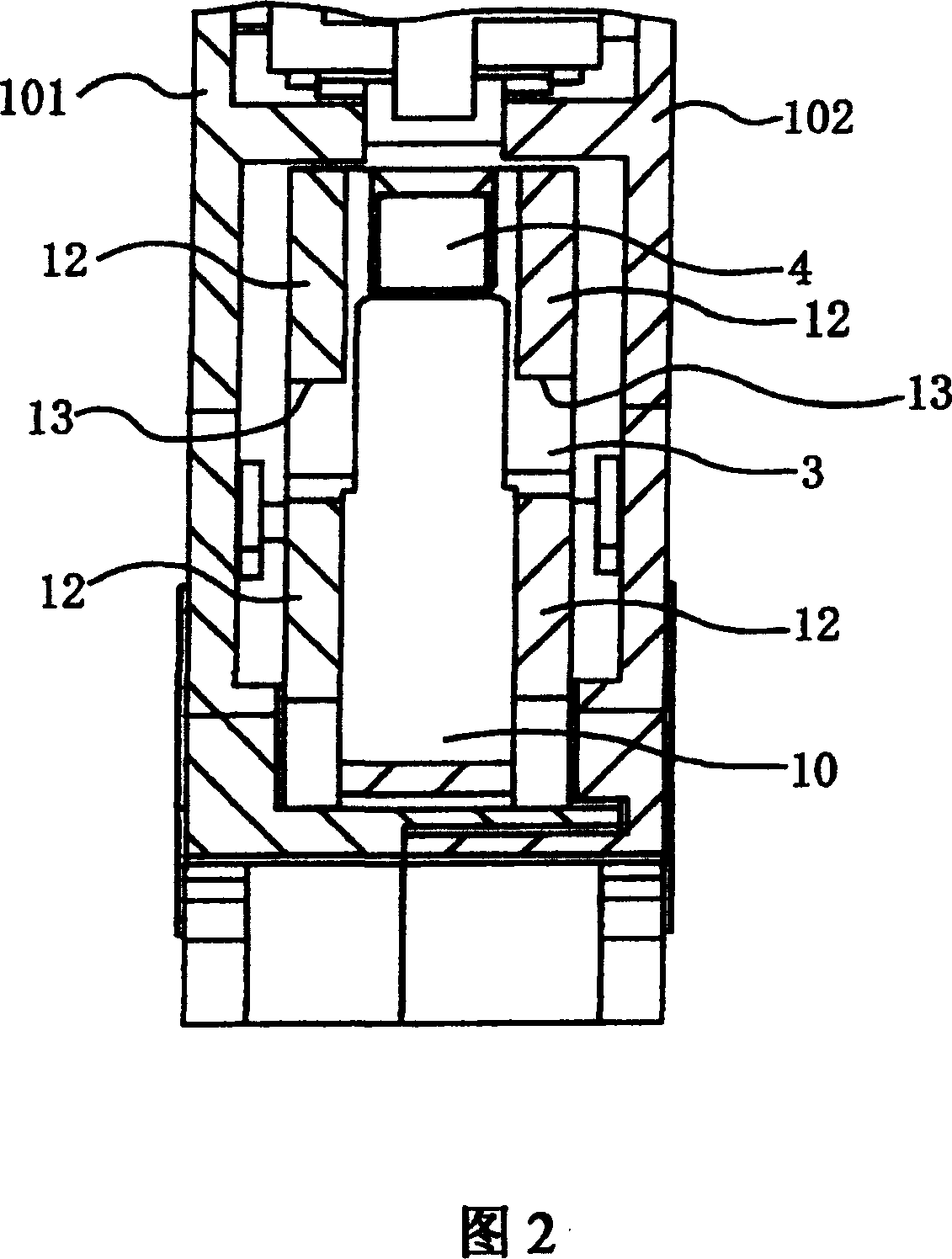

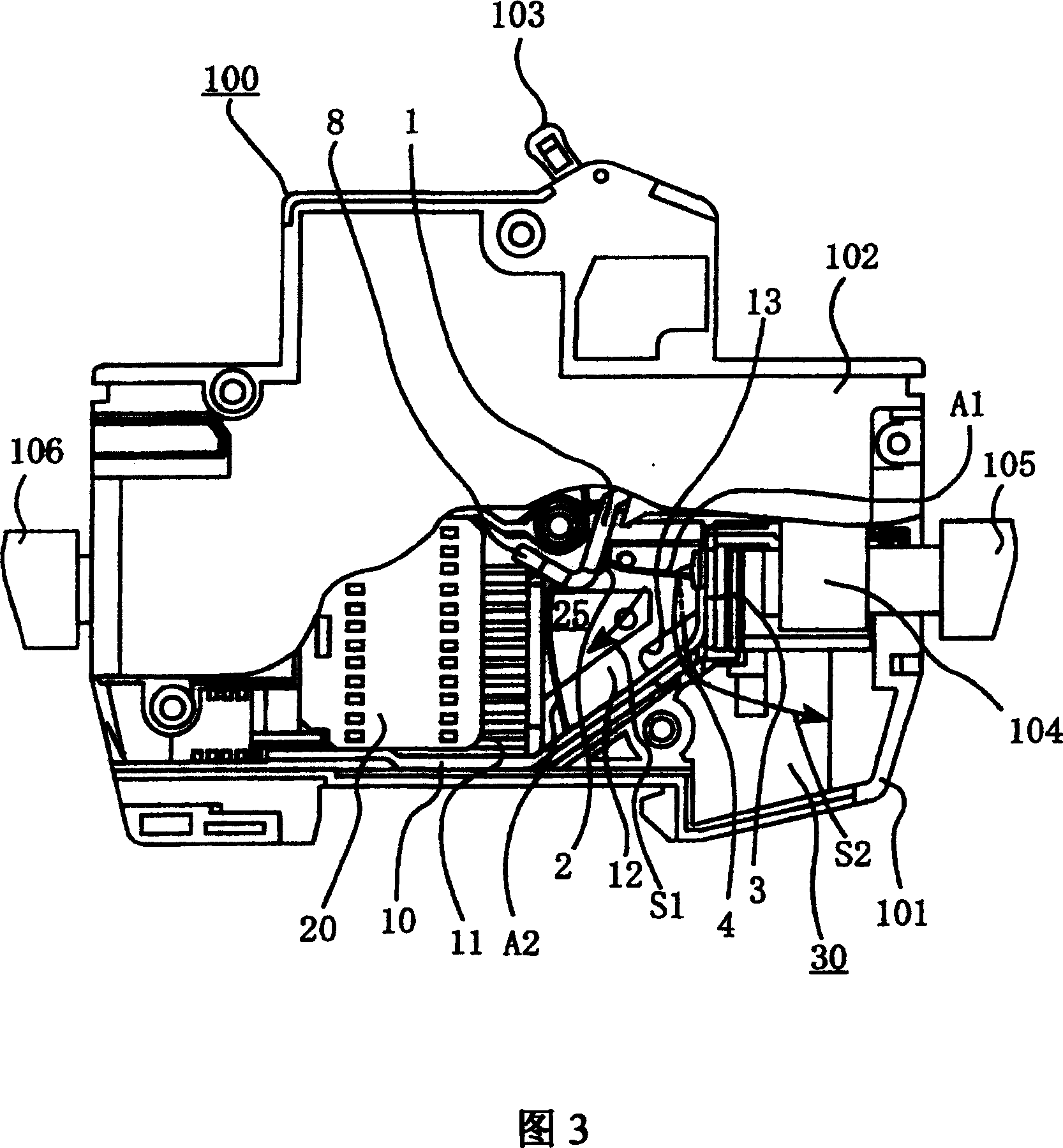

[0023] Fig. 1 is a front view of a circuit breaker in an off state according to Embodiment 1 of the present invention, showing the inside thereof with a part cut away. Fig. 2 is a cross-sectional view along the line A-A in Fig. 1, and the cut-away part in Fig. 1 is also shown for convenience. In addition, FIG. 3 is a front view schematically adding the arc operation and arc flow during the breaking operation to FIG. 1 , and FIG. 4 is an enlarged perspective view of the arc protector used in Embodiment 1 of the present invention.

[0024] In FIG. 1 , a circuit breaker 100 is constituted by an insulating case composed of a base 101 and a case 102 each formed of synthetic resin. An opening and closing mechanism (not shown) is accommodated in the base 101 , and a handle 103 associated with the opening and closing mechanism protrudes from the insulating case and can be operated by hand from the outside, as is well known. In addition, 105 is a power-side conductor connected to the ...

Embodiment approach 2

[0033] Fig. 5 is a partial sectional front view of a circuit breaker according to Embodiment 2 of the present invention, and corresponds to Fig. 1 . In the figure, the parts identical or corresponding to those in FIG. 1 are denoted by the same reference numerals. In FIG. 5 , the discharge hole 14 is provided in a part of the base 101 , and the cooling plate 15 is more preferably provided in the interior thereof, and it is completely the same as that of FIG. 1 . The gas introduced into the arc gas introduction chamber 30 is preferably discharged to the outside through the discharge hole 14 (see FIG. 6 ) provided in the susceptor 101 . The size of the discharge hole 14 can be arbitrarily set within a range in which the exhaust gas discharged from the discharge hole 14 to the outside does not short-circuit to ground due to contact with a metal object existing therearound. In addition, the cooling plate 15 provided inside the discharge hole 14 is used to cool the gas, for example...

Embodiment approach 3

[0035] Fig. 7 shows the circuit breaker in Embodiment 3 of the present invention, (a) is a cross-sectional view along the A-A line in Fig. 1, corresponding to Fig. 2, (b) is a partially enlarged oblique view near its arc flow path, Comparable to Figure 4. In the figure, the same or corresponding parts as those in Fig. 4 are denoted by the same reference numerals. In Embodiment 1 above, when connecting the two chambers of the arc gas introduction chamber 30 and the arc generating chamber 25, the notch 13 for cutting the arc protector 12 is provided. A cutout portion 16 is provided. Therefore, even if a part of the arc runner 10 is cut off, there is no problem as long as the welding characteristics of the arc runner 10 are satisfied.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com