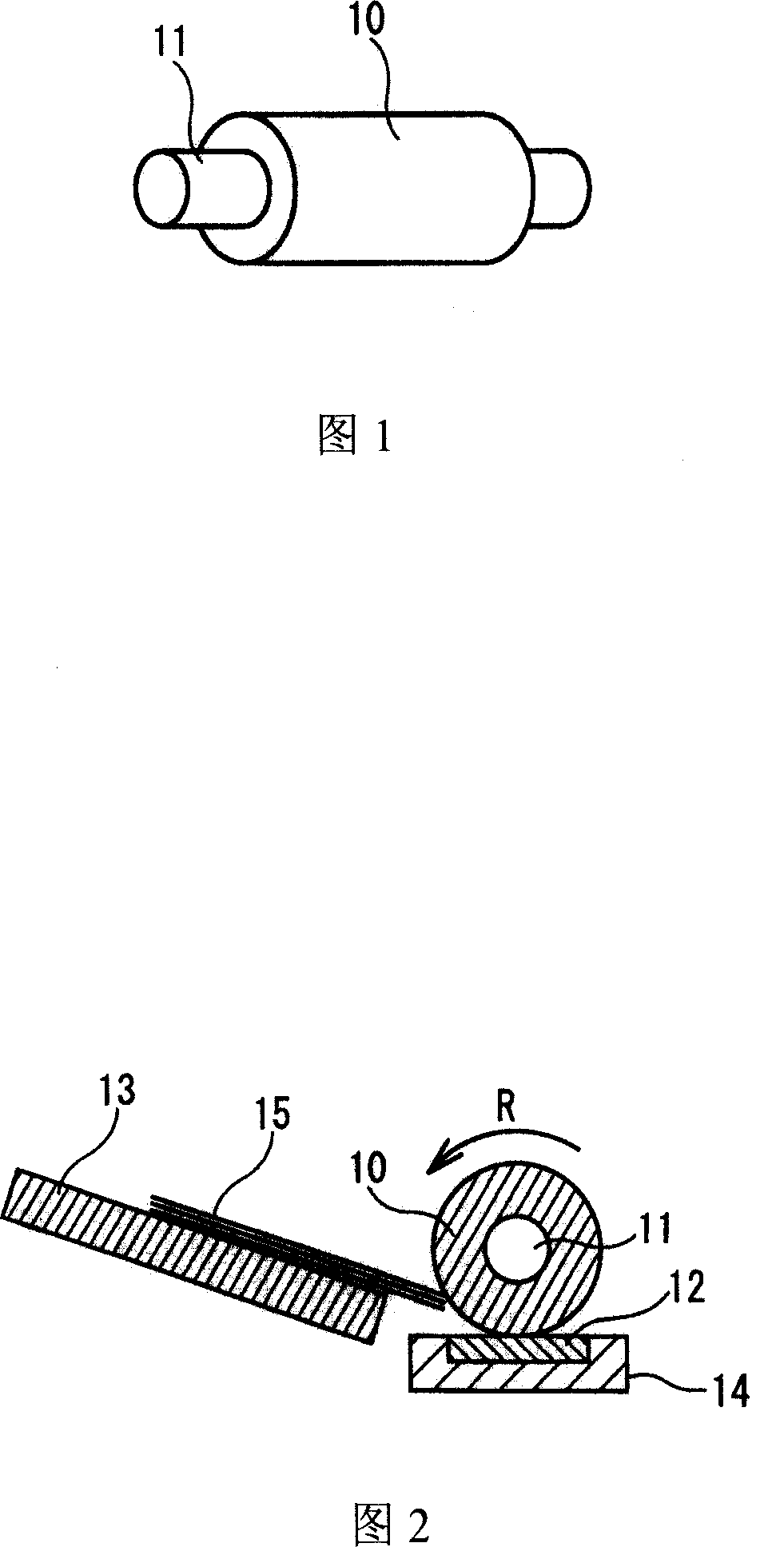

Paper feed roller

一种给纸辊、外层的技术,应用在给纸辊领域,能够解决渗出、没有考虑阻止橡胶组合物物质迁移等问题,达到长使用寿命、减少抖动现象、高耐磨性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

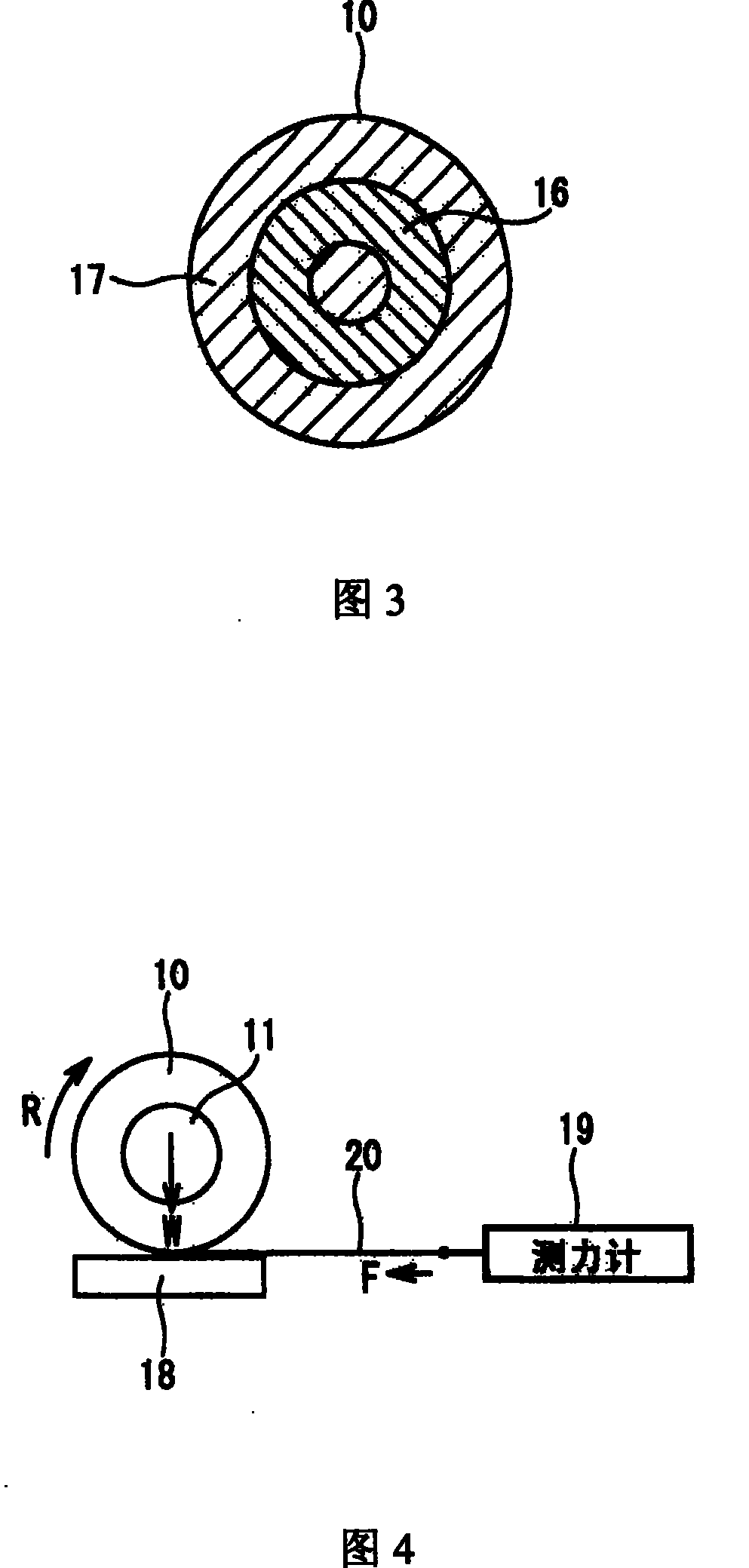

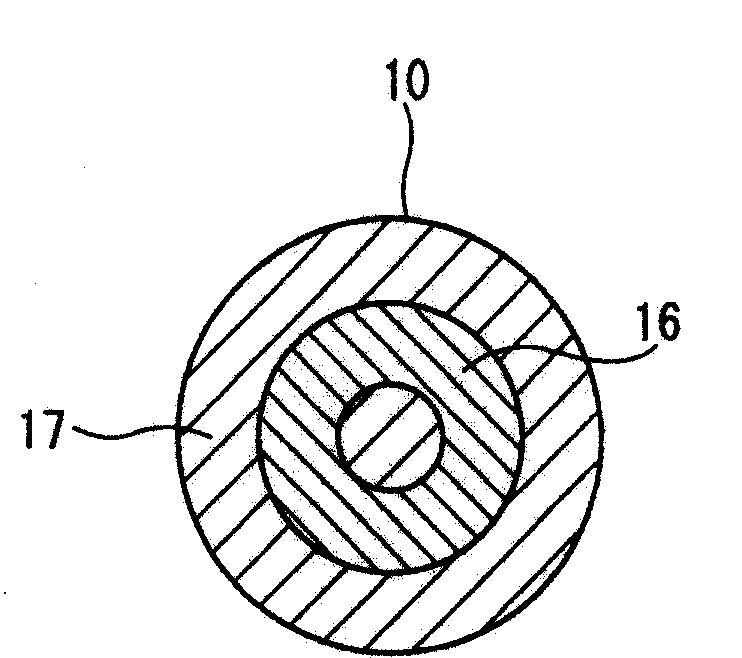

[0088] Embodiment 1~5 and comparative example 2~3

[0089] (i) Forming the inner layer

[0090] Put the rubber composition specified in Table 2 into a prefabricated mold, and vulcanize under pressure at 160° C. for 30 minutes. Thus, a cylinder with an inner diameter of φ9mm, an outer diameter of φ15mm and a length of 60mm is obtained. Finally, the cylinder is cut into rubber rollers with a length of 10mm.

[0091] (ii) forming the outer layer

[0092] Put the rubber composition specified in Table 2 into a prefabricated mold, and vulcanize under pressure at 160° C. for 20 minutes. Thus, a cylinder with an inner diameter of φ14mm, an outer diameter of φ21mm and a length of 60mm is obtained. Next, the prepared cylinder was ground with a cylindrical grinder until the outer diameter became φ20 mm. Finally, the cylinder is cut into rubber rollers with a length of 10 mm.

[0093] (iii) Forming a paper feed roller with a double-layer structure

[0094] Insert the shaft into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com