Reciprocating guide mechanism for needle loom

A guiding mechanism and acupuncture machine technology, applied in the direction of acupuncture machine, engine lubrication, mechanical equipment, etc., can solve the problems of difficult assembly, complicated but not simple, acupuncture machine loses its price advantage, etc., and reduce lubricating oil. The probability of leakage, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

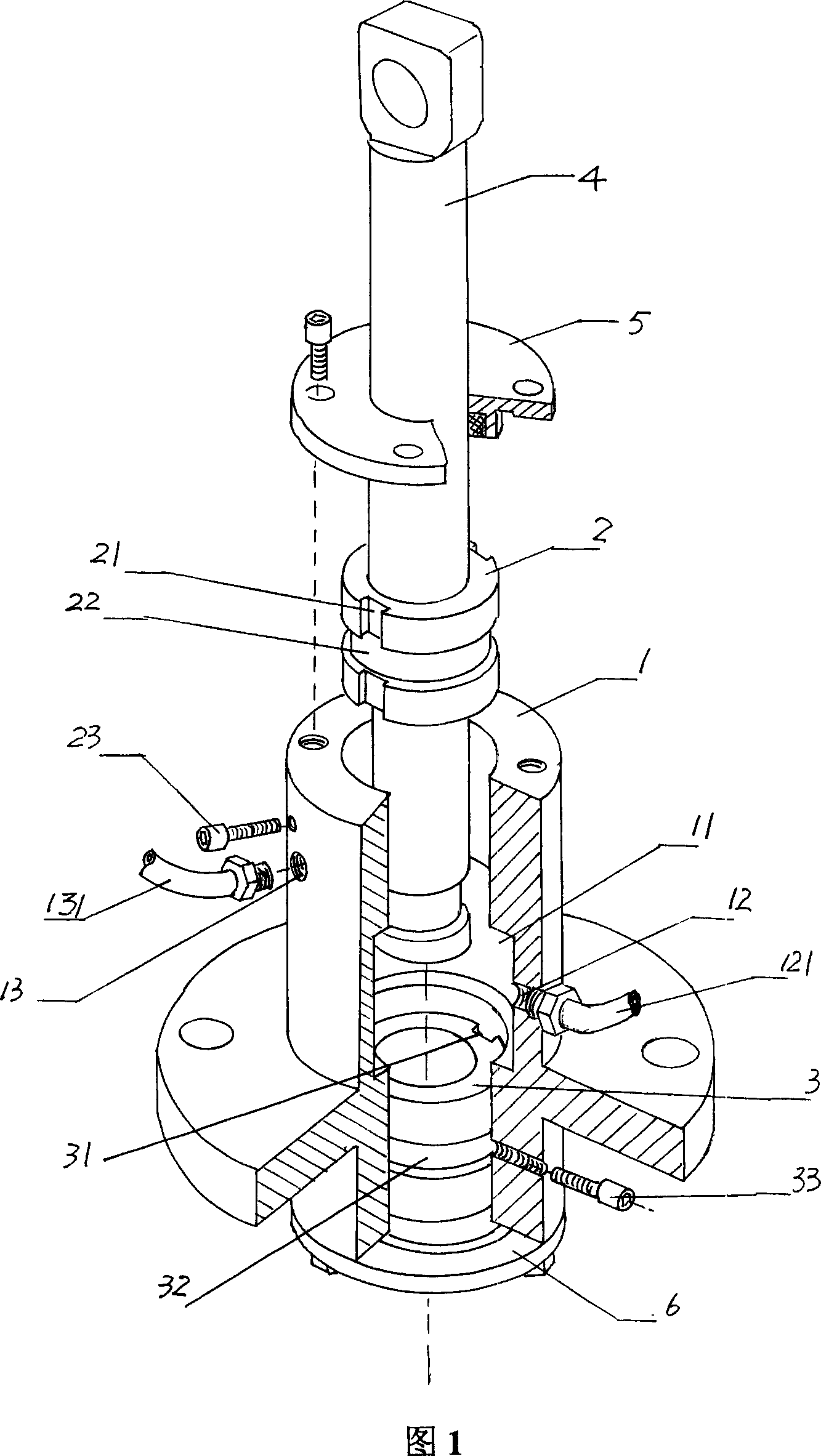

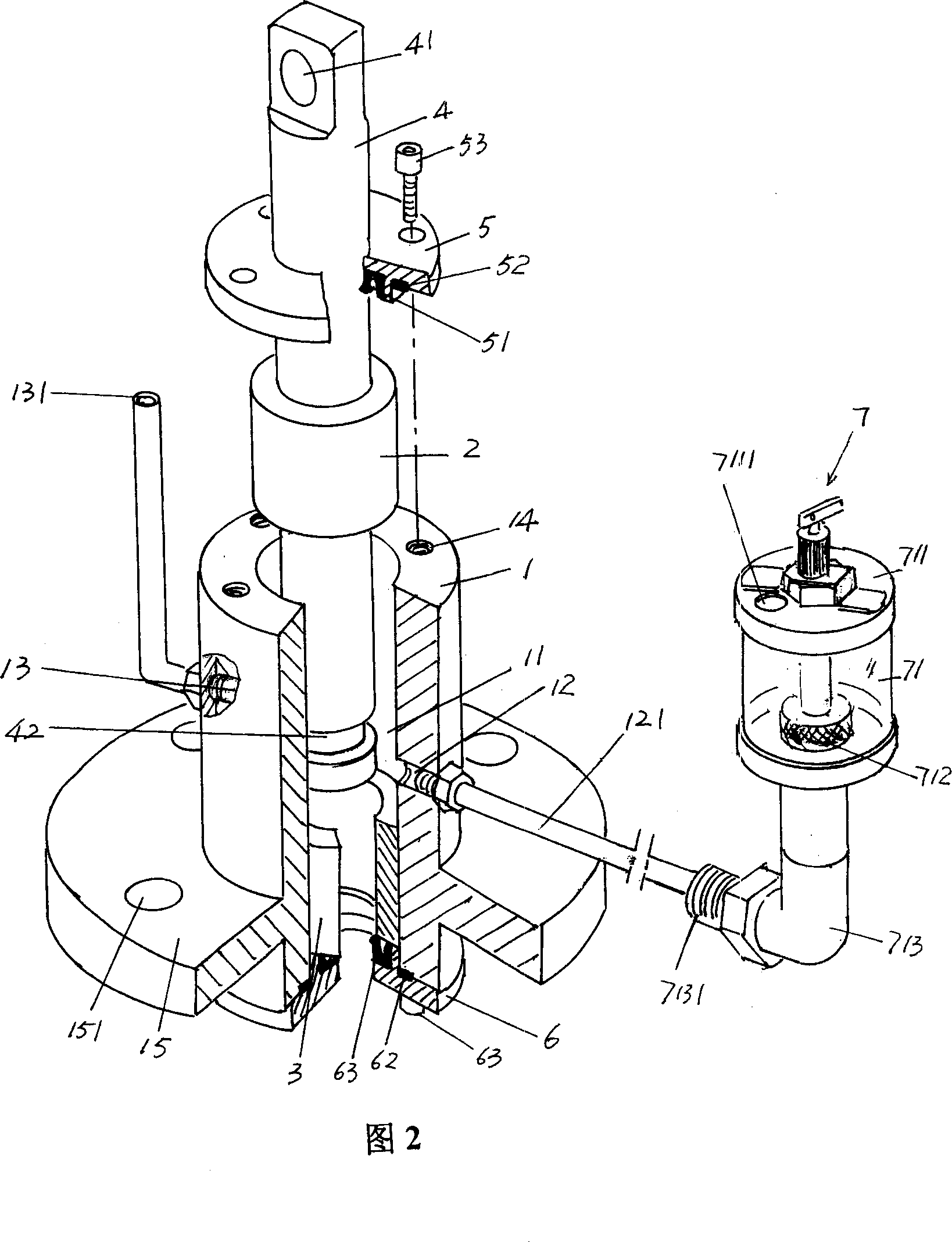

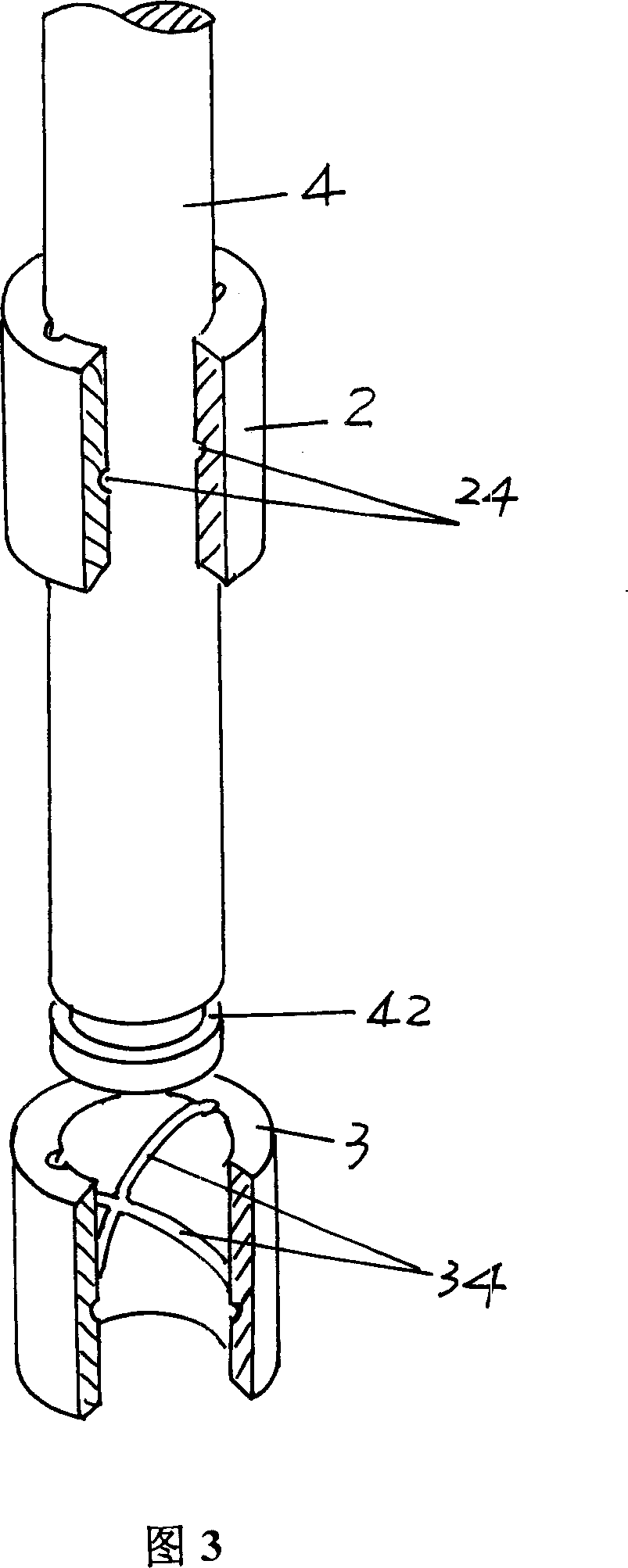

[0021] Please refer to Figure 2 and Figure 3, the longitudinal section of the guide sleeve 1 is in a convex shape, the upper end surface is provided with a screw hole 13, and the lower part is expanded into a mounting flange 15, and the upper part of the mounting flange 15 is provided with a mounting and fixing Hole 151. The cavity of the guide sleeve seat 1 is constituted as an oil chamber 11 , and the first and second through holes 12 and 13 are respectively opened on the side of the guide sleeve seat 1 and communicate with the oil chamber 11 respectively. As an embodiment, the oil storage container 7 shown in this figure as a lubricating oil source device is indirectly connected with the first through hole 12 through the oil inlet pipe 121 . Further, one end of the oil inlet pipe 121 (the left end shown in the figure) is threaded or welded with the first through hole 12, and the other end of the oil inlet pipe 121 (the right end shown in the picture) is threaded or welded w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com