Gas aspiration and compression system, especially for gas compressors

A gas compressor and compression system technology, applied in the field of gas compressors, can solve problems such as insufficient pistons, and achieve the effects of avoiding the reduction of the surface area, improving efficiency, and avoiding the reduction of volumetric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

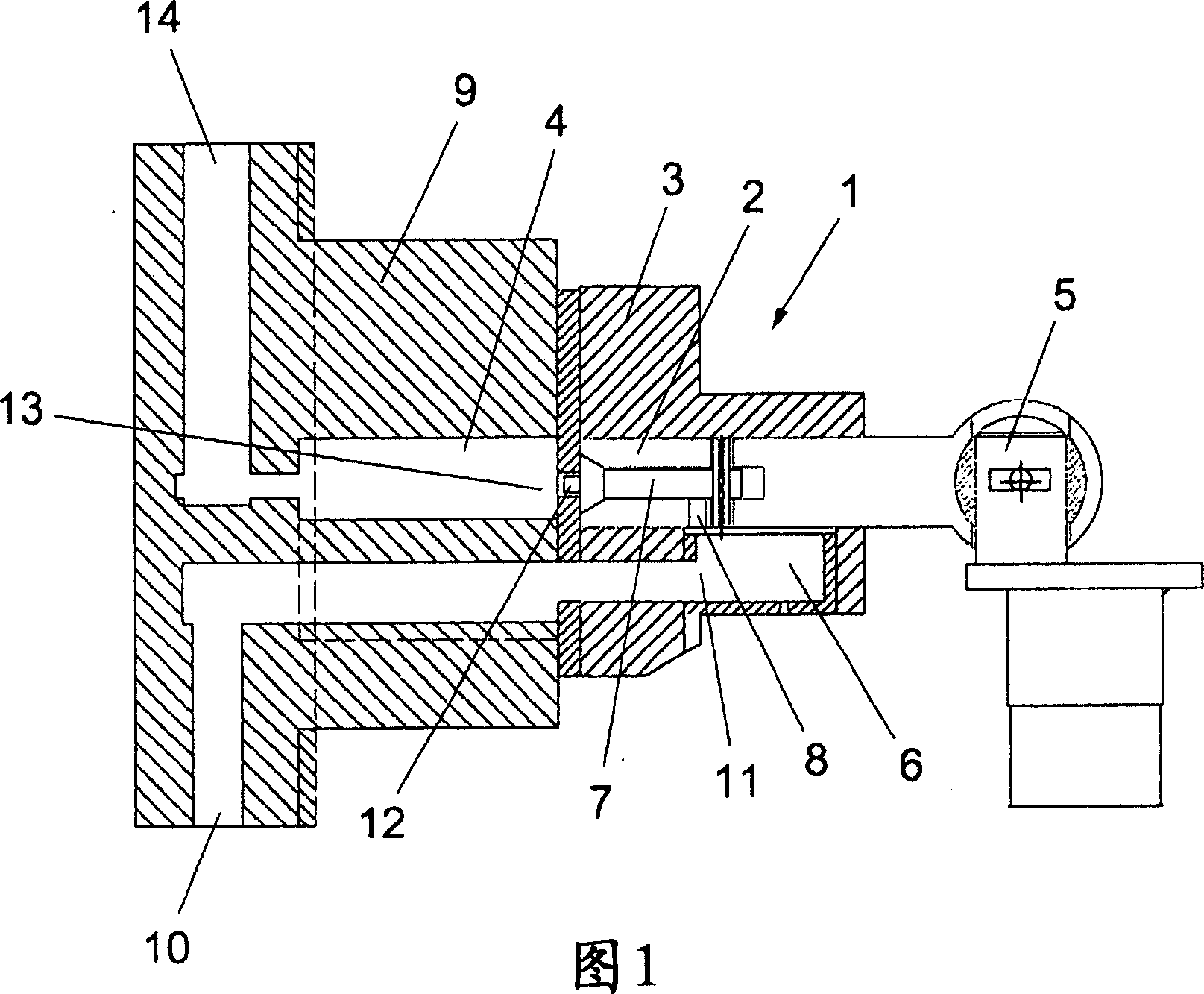

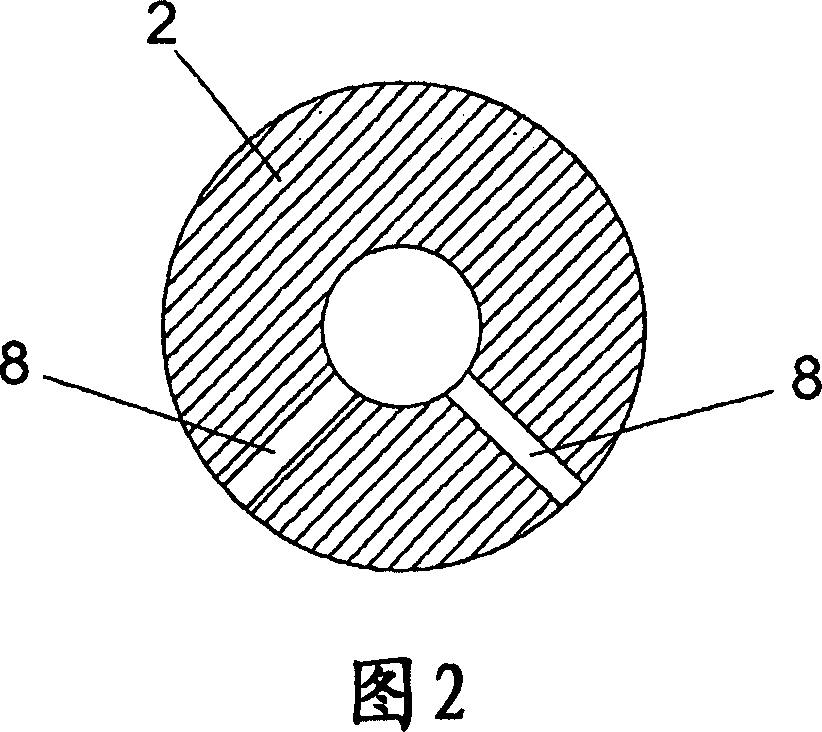

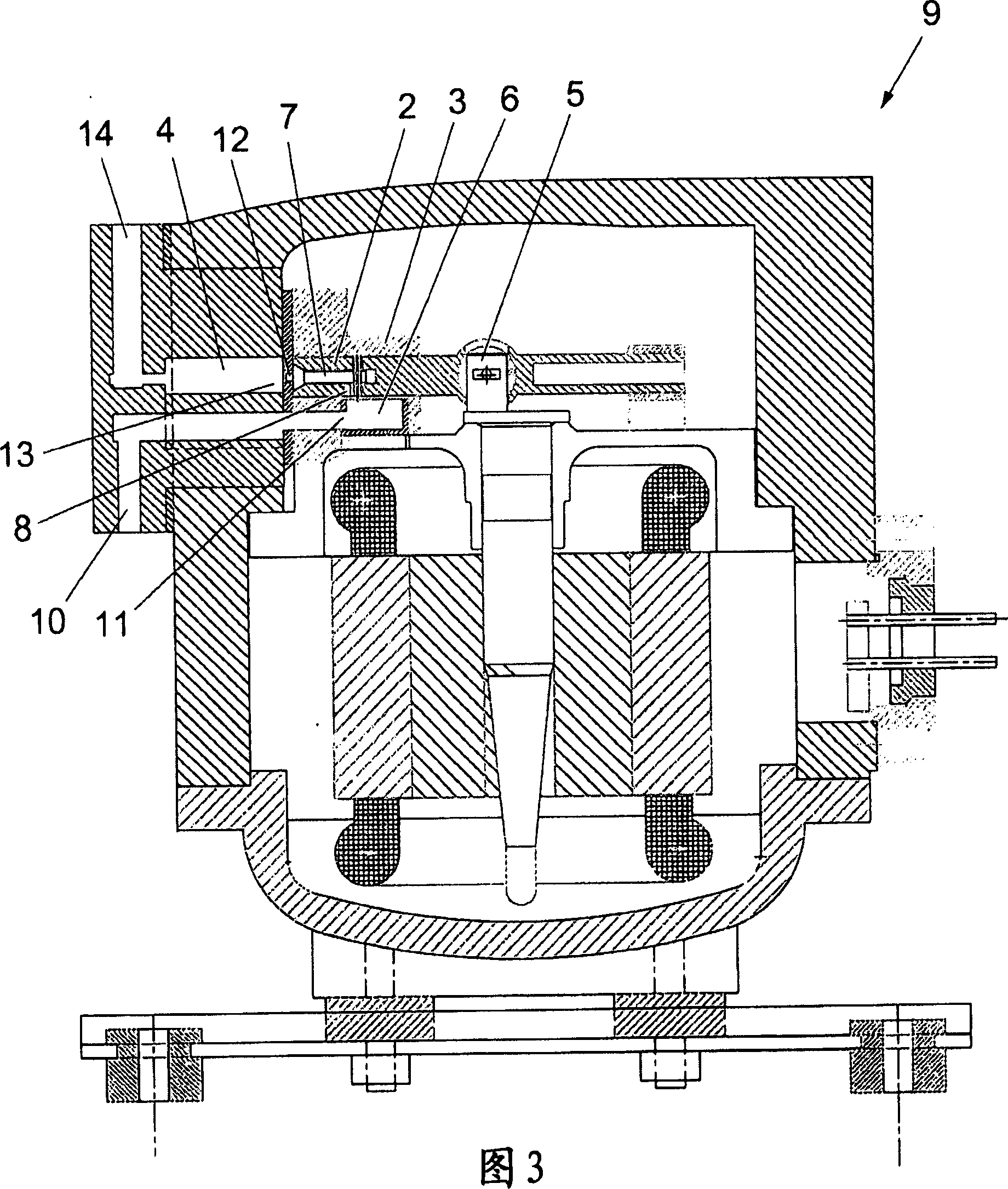

[0023] As shown in Figure 1, the gas suction and compression system 1 of the present invention comprises a piston 2 of very small diameter, preferably less than 11 mm, which cooperates with a cylinder 3 of a compression chamber 4, said piston 2 being in such a Connect to the scotch yoke mechanism 5 in the way. The system 1 of the present invention also includes a gas suction port 6 arranged on the side area of the cylinder 3 near the bottom dead center of the piston 2, and a P-V optimization valve 7 (P-V is pressure-volume) arranged in the center of the piston 2 , are radially formed in the piston 2 and connect the suction port 6 and the two orifices 8 of the P-V optimization valve 7 . The orifice 8 of the piston 2 can thus move along the suction opening 6 so that gas enters the compression chamber 4 during the suction stroke of the piston 2 and prevents the gas from passing through during the compression stroke of the piston 2 . With this design, there is no need to use a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com