Vibration transfer rate reducing device and method

A technology of vibration transmission rate and transmission device, which is applied in the direction of vibration suppression adjustment, shaft, mechanical equipment, etc., which can solve the problems of reduced noise and vibration performance in the car, increased noise in the car, and poor noise and vibration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

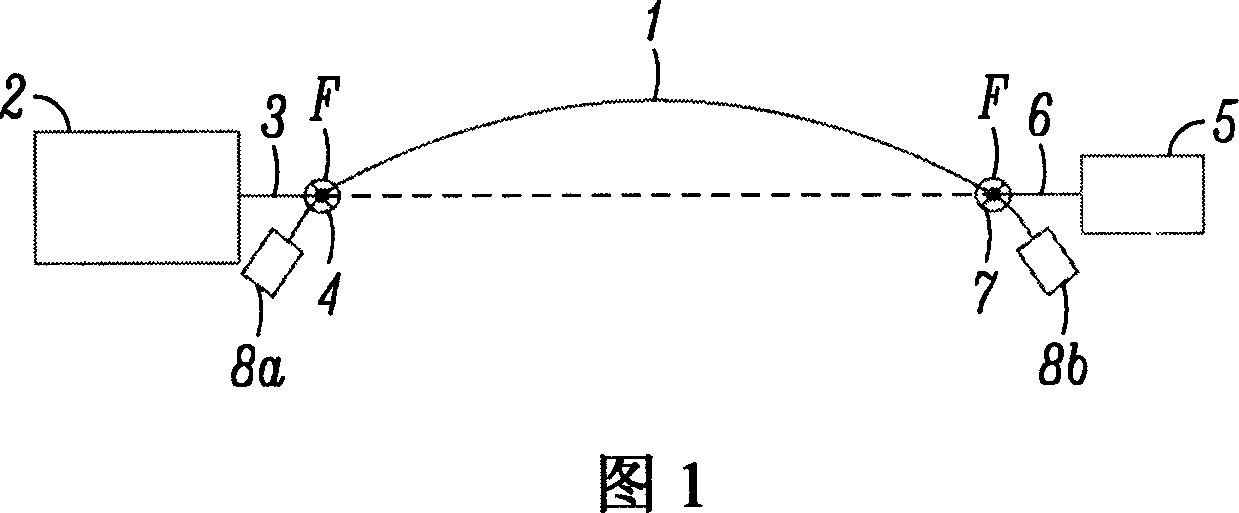

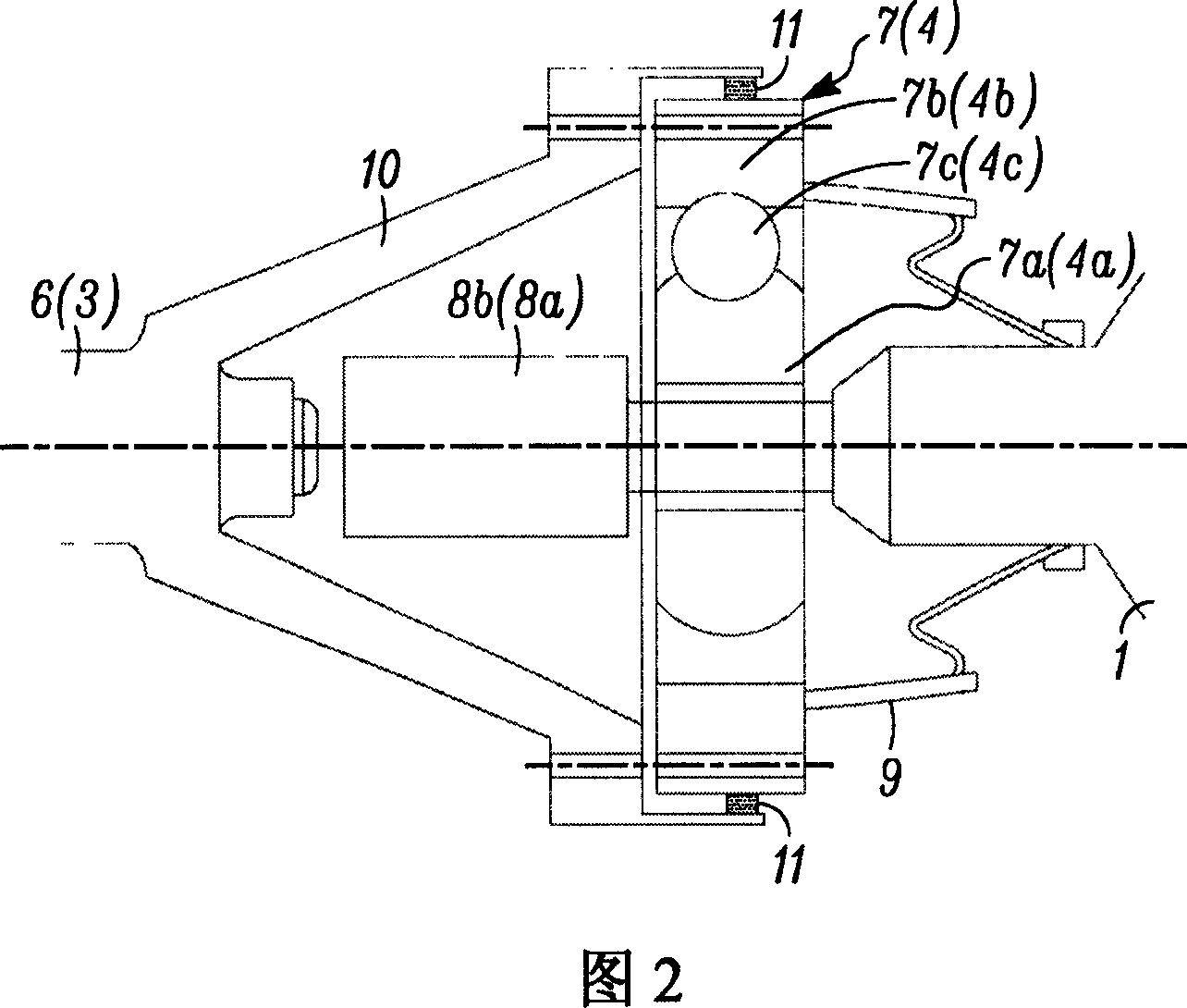

[0018] The damper disclosed in the aforementioned Japanese Kokai Patent Application No. 2003-247596 cannot suppress the vibration of the joint because the node of the primary bending vibration of the propeller shaft is axially closer to the center than the joint. Therefore, the damper cannot suppress the vibration of the differential or transmission connected to the drive shaft. The vibration of the input shaft end of the differential and the output shaft end of the transmission is transmitted to the panel of the vehicle body, causing the panel to vibrate. Therefore, the noise in the vehicle body is increased, and the noise and vibration performance is deteriorated.

[0019] According to an example of the vibration transmissibility reducing device disclosed herein, the vibration transmissibility reducing device can reduce the vibration transmissibility of a shaft that transmits a rotational driving force of a propeller shaft or the like, thereby improving noise and vibration p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com