Electric heat exchanger and ventilation system using same

A technology of an exchanger and a heat exchange element, which is applied in the field of ventilation systems, can solve the problems such as the reduction of the electric heat efficiency of the electric heat exchanger, the lower efficiency of the electric heat exchanger, and the inability to effectively perform heat exchange operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

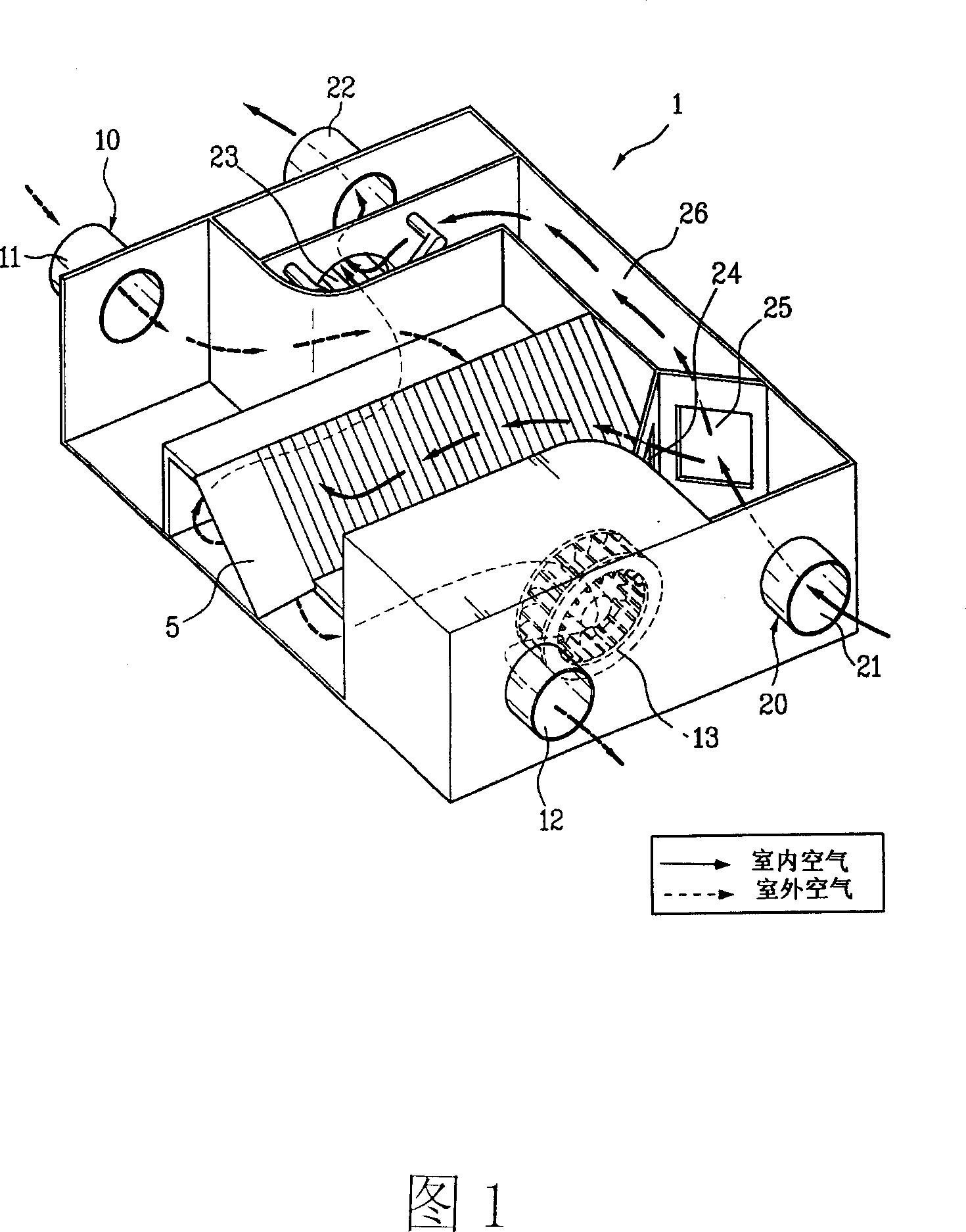

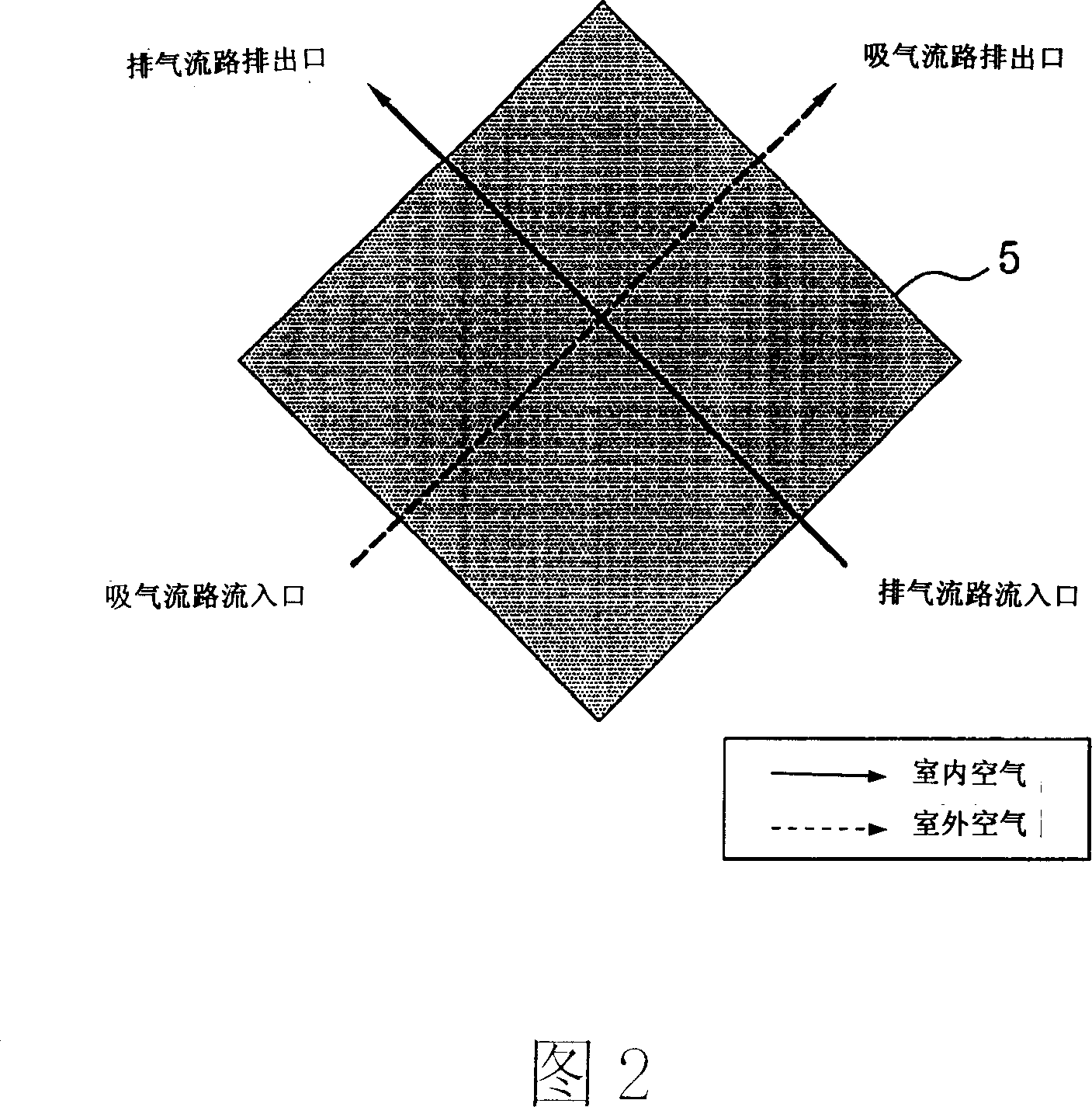

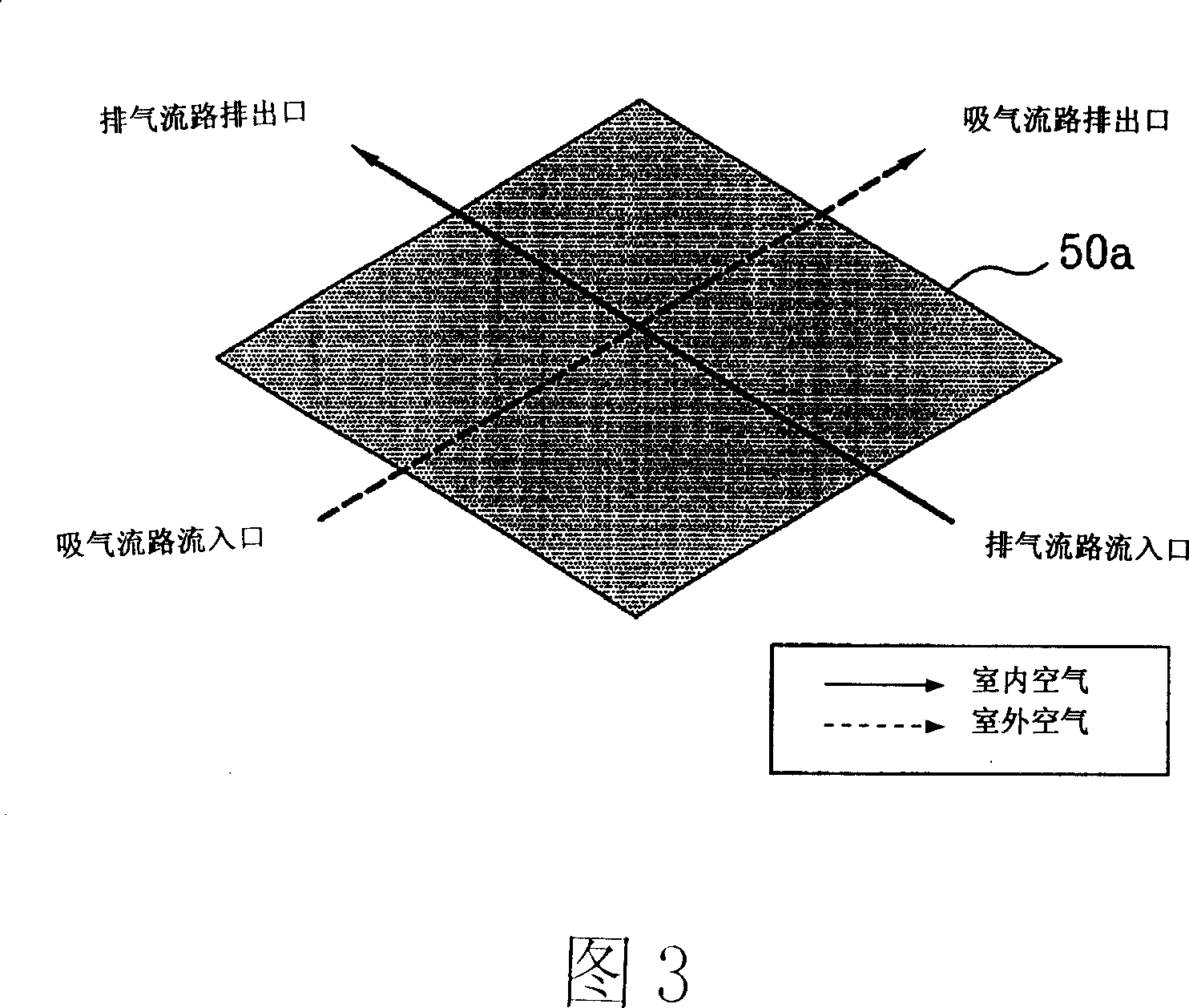

[0058] Next, the first embodiment of the electric heat exchanger in the present invention will be described with reference to accompanying drawings 2 to 4b.

[0059] As shown in Fig. 2 and Fig. 3, the basic structure of the first embodiment of the electric heat exchanger in the present invention is the same as that of the conventional electric heat exchanger shown in Fig. 1 . That is, it includes: a heat exchange element 50a, which makes outdoor air and indoor air perform heat exchange; a suction fan 13, which is connected to the above-mentioned suction flow path 10, sucks the above-mentioned outdoor air, and discharges it into the room; The air fan 23 is connected to the above-mentioned exhaust flow path 20, sucks the above-mentioned indoor air, and discharges it to the outside. However, the cross-sectional shape of the heat exchange element 50a is different from that of the prior art, and is formed in a polygonal shape whose length in the horizontal or vertical direction is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com