Novel capacity-enlarging induction furnace body and process

An induction furnace, a new type of technology, is applied in the field of smelting and processing of metal materials, which can solve the problems of insufficient use of magnetic field energy, waste of electromagnetic energy, unsafe inclined crucible, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

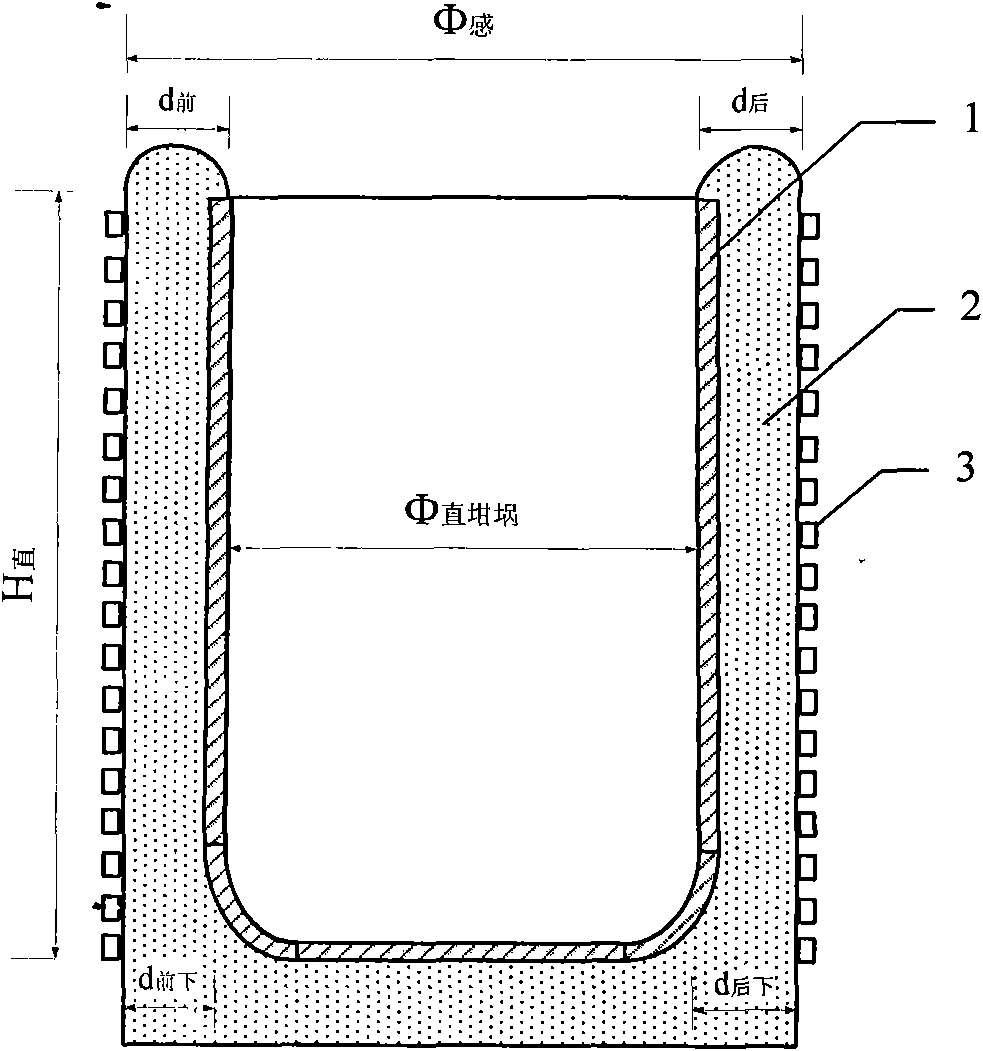

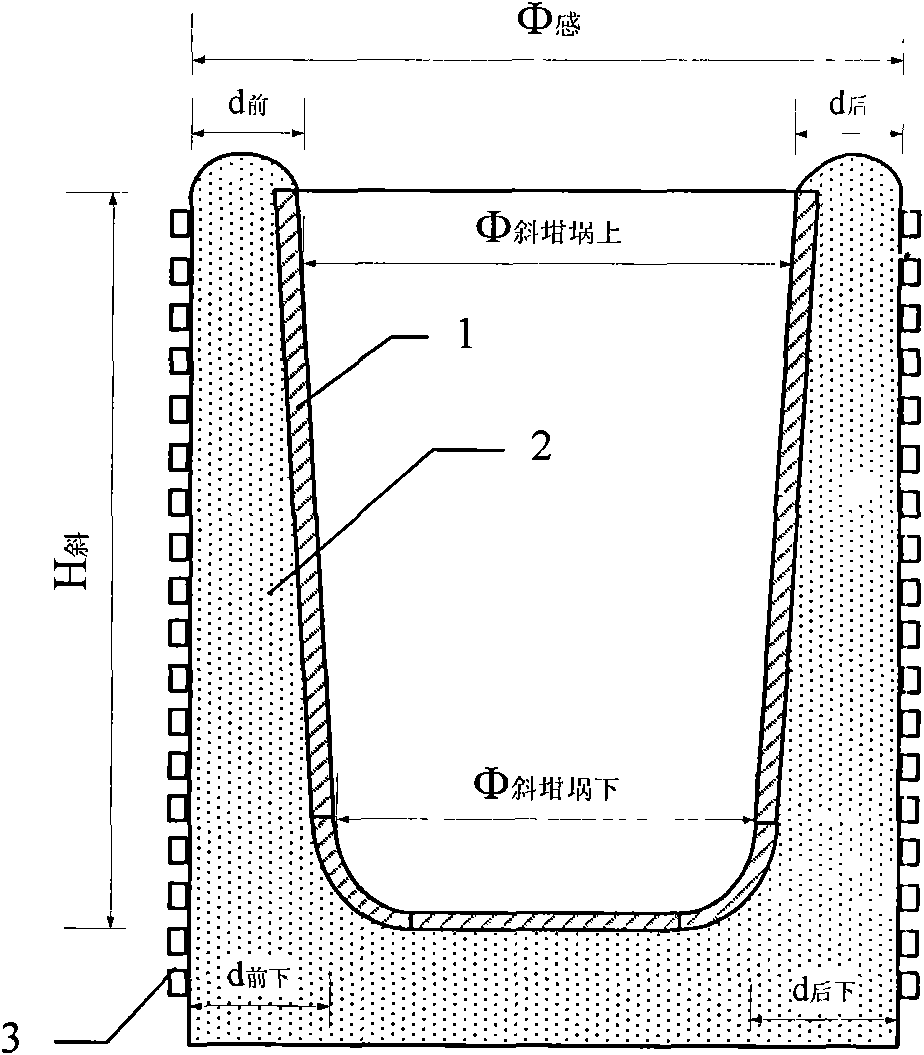

[0014] Example: 1t medium frequency induction furnace, Φ 感 =1200mm, Φ 直坩埚 The crucible 1 of =800mm is placed on the bottom of the furnace that has been built and aligned with the lower edge of the first induction coil under the induction coil 3 on the same horizontal plane, and then the crucible 1 is moved to the front to make the furnace wall of the crucible 2 The front half is 80mm thinner than the back half. Build the crucible furnace wall 2. Smelting the high-speed tool steel M42 of American ASTM standard, producing 80 furnaces, under the same number of furnaces, compared with the same power consumption, the average output of each furnace increased by 11%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com