Dynamic test device for composite perforator

A technology of dynamic testing and compound perforation, applied in the directions of measurement, production of fluids, wellbore/well components, etc., can solve the problems of complex testing process, small physical memory, few sampling points, etc., and achieve accurate test results and test costs. Low, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

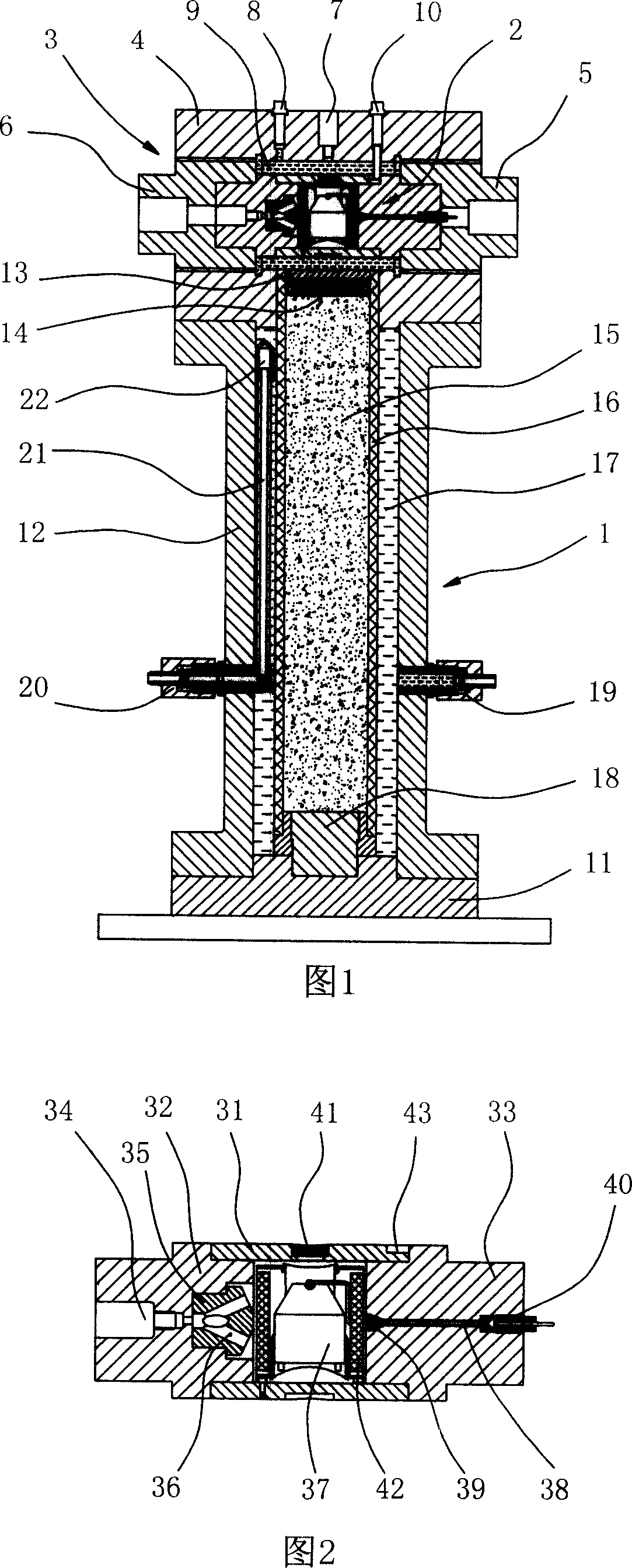

[0014] The content of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] As shown in Figure 1: the test device is mainly composed of three parts: the simulated target body 1, the composite perforating gun unit 2, and the high-pressure container 3 placed on the top of the simulated target body. The data processing adopts the existing mature technology. The pressure sensor on the device obtains signals, and the p-t dynamic curves in the composite perforator gun and the annular space are obtained through acquisition, signal amplification and computer.

[0016] The high pressure container 3 is composed of a shell 4 , a right end cover 5 and a left end cover 6 . The left and right end caps are provided with through holes, and the two end caps are connected with the inner hole of the shell 3 by threads, and the joint surfaces are provided with seals. The outer shell 4 can be cylindrical or prismatic, and this example is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com