Quality detector of punched-card and its detecting method

A detector and cardboard technology, which is applied in the field of punched cardboard, can solve problems such as inability to adapt to cardboard specifications, changes, and high relative position accuracy requirements, and achieve low production costs, improve accuracy, and eliminate external factors. interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

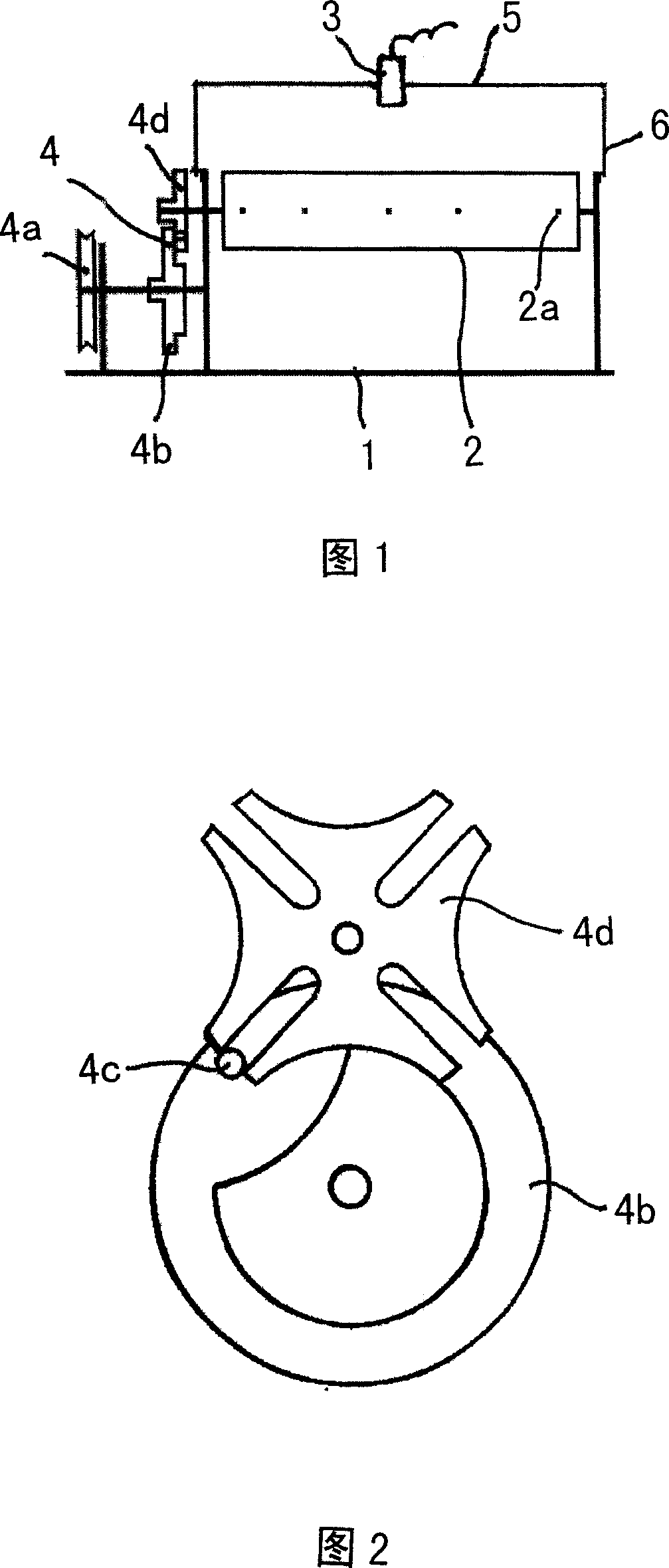

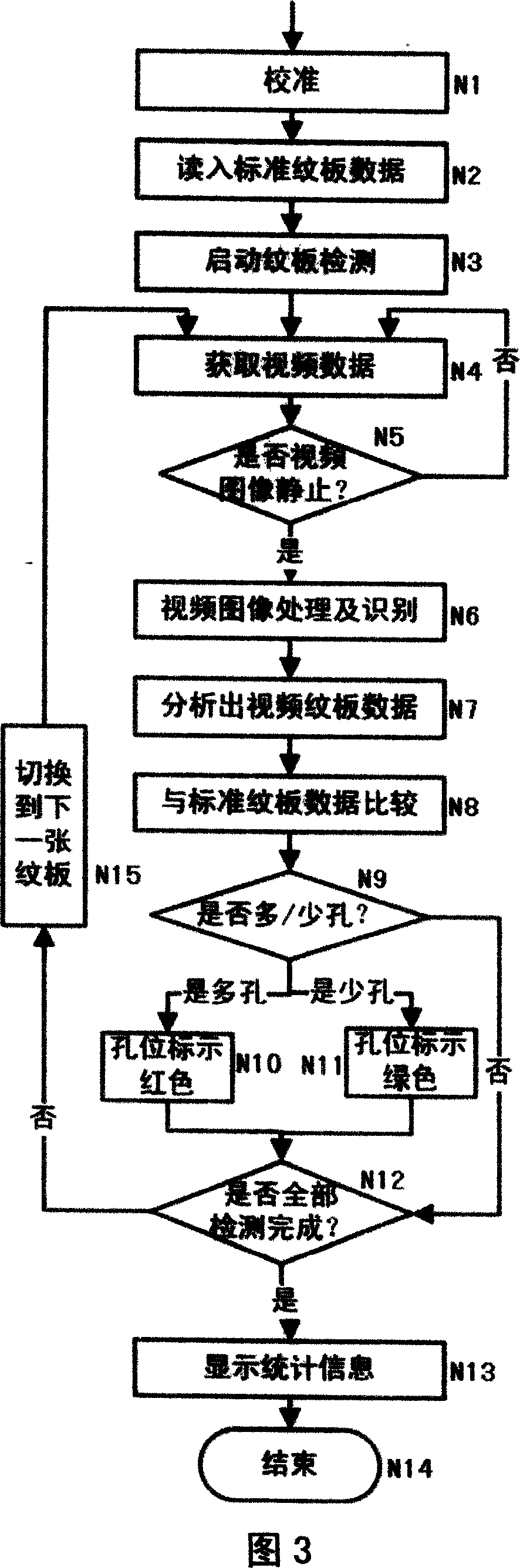

[0015] A kind of perforated corrugated plate quality detector, its structure is shown in Fig. 1 and Fig. 2, comprises support 1, arranges the cylinder 2 that perforated corrugated plate is used, and this cylinder 2 is arranged horizontally, is installed on the support 1, is equipped with A plurality of positioning pins 2a matched with the positioning holes of the perforated cardboard are characterized in that: a camera 3 and a transmission mechanism 4 are provided, the camera 3 is installed on the cross bar 5, and the two ends of the cross bar 5 are fixed on the bracket through the column 6 1; the transmission mechanism 4 is composed of a pulley 4a driven by a motor through a belt, a thumb wheel 4b, a pull pin 4c, and a sheave 4d. The sheave 4d is provided with 4 grooves that match the pull pin 4c, and the pulley 4a and the dial 4b are coaxially arranged, the shaft is installed on the bracket 1, the sheave 4d and the drum 2 are coaxially arranged, the positioning pin 2a is enga...

Embodiment 2

[0019] If it is replaced with another punched cardboard with different specifications for quality inspection, it is only necessary to adjust the position of the positioning pin on the drum. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com