Bearing support structure for turbomolecular pump

A technology of turbomolecular pump and bearing support, applied in the direction of rotating bearing, bearing, rigid support of bearing parts, etc., can solve the problem of bearing overheating, bearing outer ring inclination to limit bearing damage, and difficulty in transferring heat from rotating shaft bearings, etc. problems, to improve bearing durability, reduce operating noise and vibration, and achieve the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

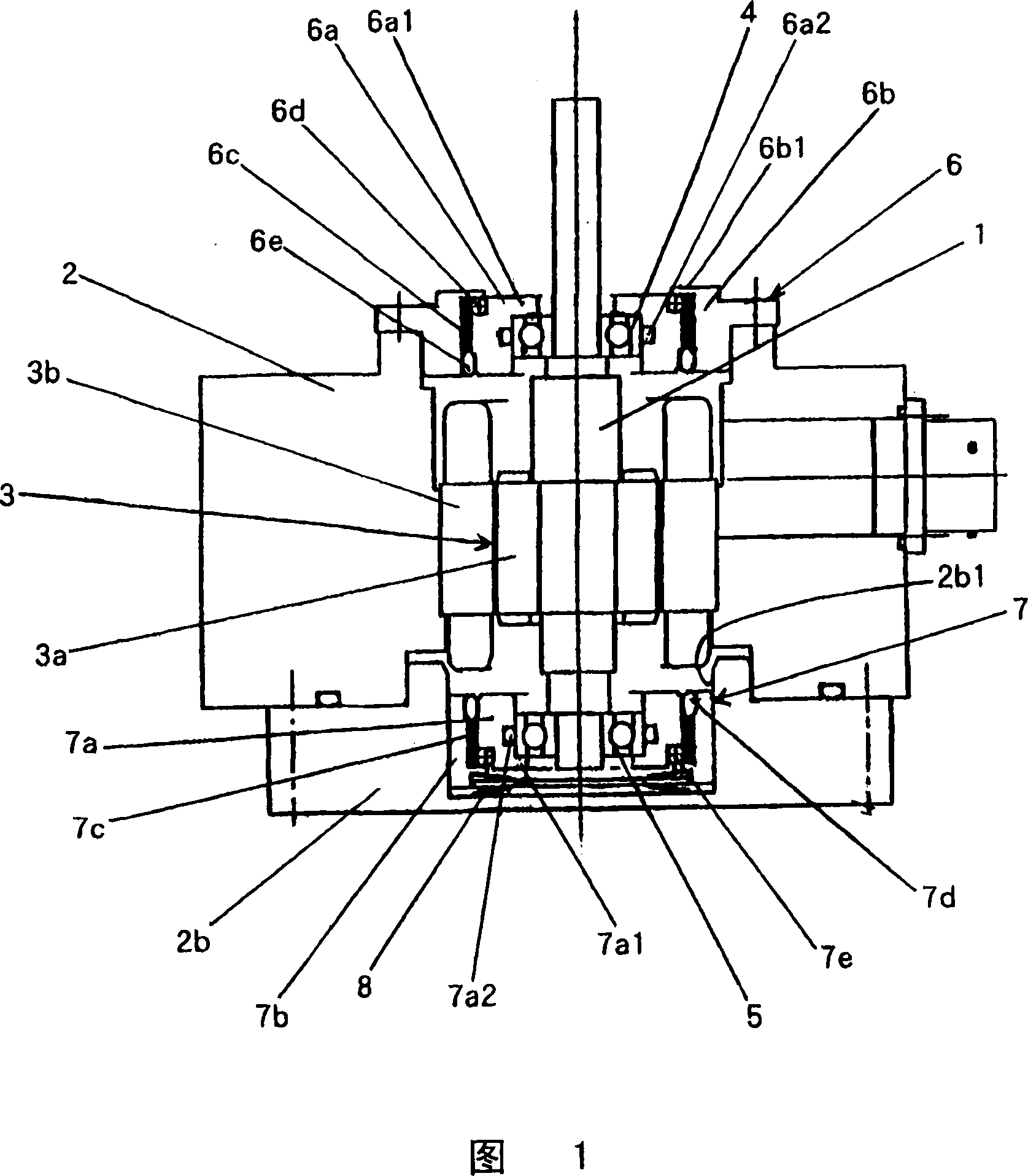

[0031] Fig. 1 is a longitudinal sectional view of a part of a turbomolecular pump having a bearing support structure of the present invention, a bearing support part, in which the rotor clamped on the upper part of the rotating shaft 1 and the rotor continuously arranged on the upper part of the intermediate housing 2 are omitted in this Fig. 1 the upper shell.

[0032] 3 denotes a motor, and the motor 3 includes a rotor 3 a fixed to the outer peripheral portion of the rotating shaft and a stator 3 b fixed to the inner peripheral portion of the intermediate case 2 .

[0033] Reference numerals 4 and 5 denote ball bearings, and the ball bearings 4 and 5 are provided above and below the motor 3 with the motor 3 interposed therebetween. These ball bearings 4 and 5 are self-lubricating types filled with grease.

[0034] 6 denotes a first bush, and the first bush 6 has an inner and outer double structure including an inner first bush 6 a on the inner peripheral side and an outer fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com