Automatic punching bagging and tying machine for mixed edible fungus material

A mixed material and stamping technology, which is applied in the field of machinery for producing edible fungi, can solve problems such as machinery for edible fungi that have not yet been seen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

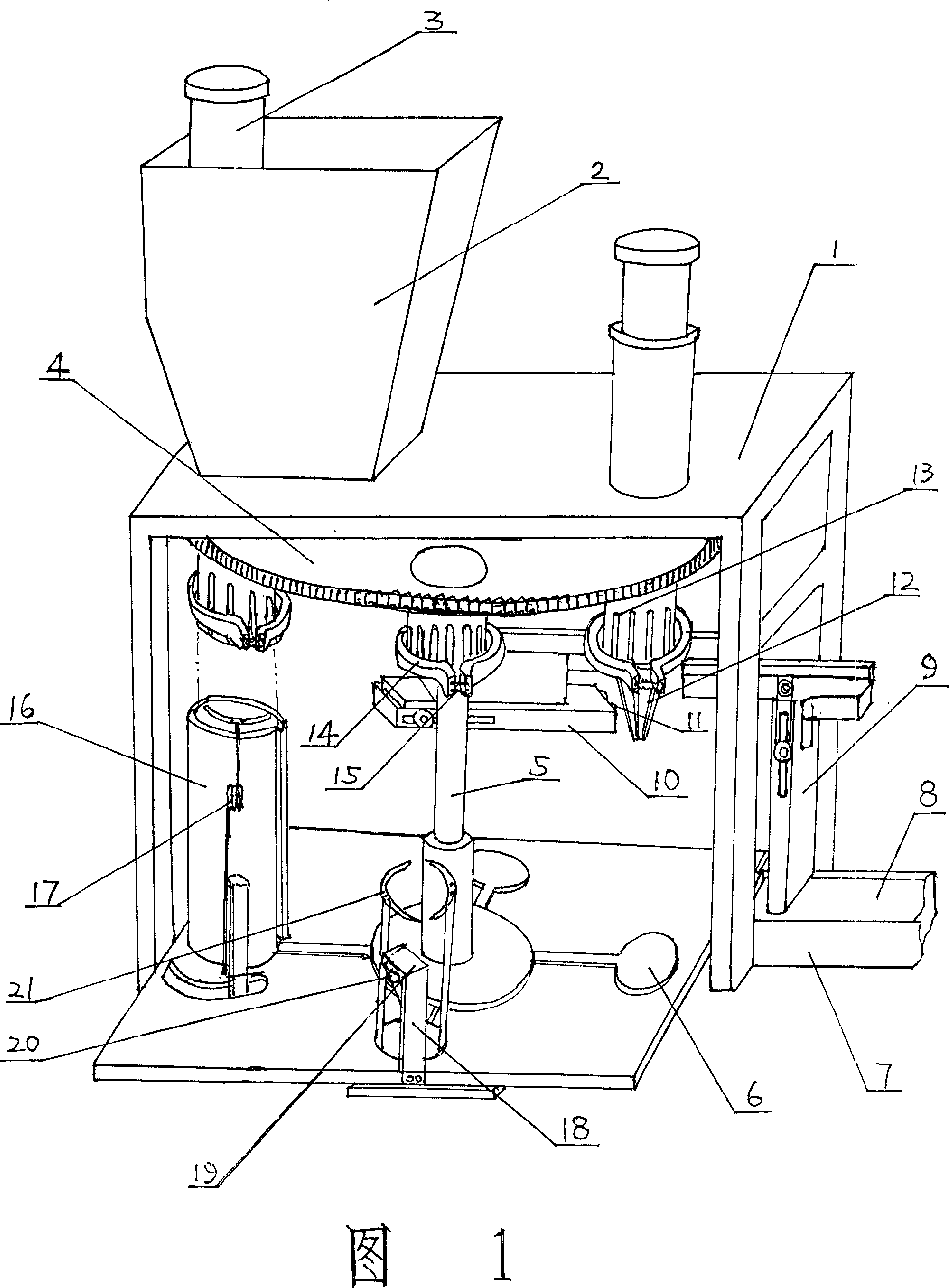

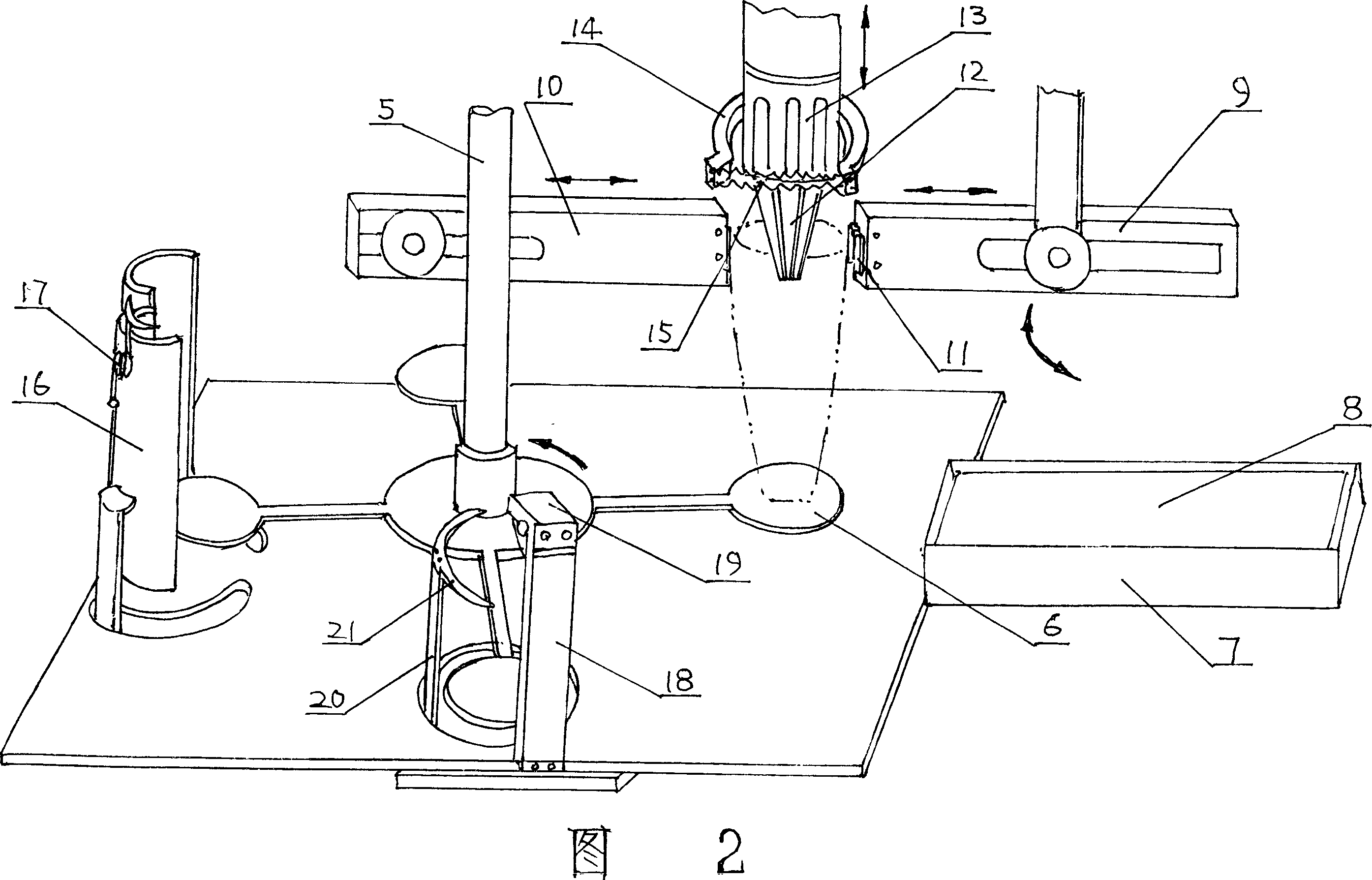

[0013] Please refer to Fig. 1 ~ Fig. 3, there is a frame 1, the upper end of the frame 1 is equipped with a bucket-type charging mechanism hopper 2 and pressing material, charging cylinder 3; Together, the station rotating disk 4 with 4 stations, the central shaft 5 and the bag supporting station rotating disk 6 are arranged; the side end of the frame 1 is provided with a bagging box 7, and the bagging box 7 is equipped with materials to be loaded. The plastic bag 8; The 4 stations of the station rotating disk and the 4 stations of the bag holding station rotating disk 6 on the bag holding station rotating mechanism are one-to-one correspondence; the station rotating disk 4 The station is respectively equipped with bag taking, bag opening, bagging, bag clamping mechanism, material pressing mechanism and cable tie mechanism; the station rotation mechanism is realized by the stepper motor installed on the frame 1 to drive the teeth around the turntable. The station is replaced a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com