Rolling mill for copper wire

A rolling mill and copper wire technology, which is applied in the direction of rolling mill control device, metal rolling stand, metal rolling stand, etc., can solve the problems of reducing usability and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

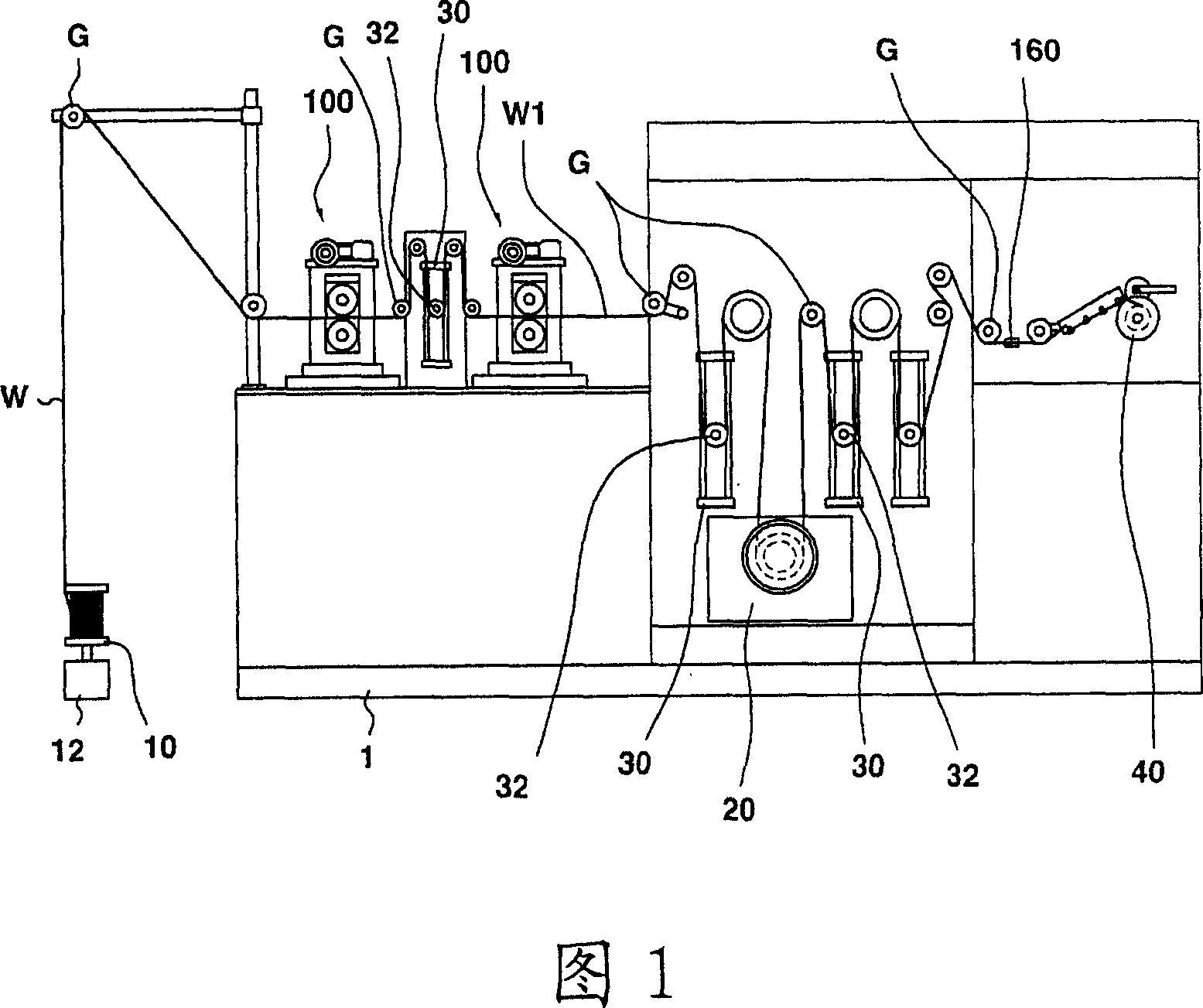

[0015] Referring to FIGS. 1 to 4 , a rolling machine for copper wire according to the present invention is configured to perform rolling, heat treatment, and coiling for collecting copper wire (W) through automatic processing.

[0016] One side of the rolling mill main body 1 is provided with a supply spool 10 on which a copper wire W is wound, and the supply spool 10 is connected to the shaft of a motor 12 and installed so as to unwind the copper wire W at a given speed. turn. This bobbin is used to prevent the copper wire W from being tangled.

[0017] The supplied copper wire W is guided to the mill roll 100 by a plurality of guide rolls G. As shown in FIG. The rolling mill roll 100 is installed on a part of the rolling mill on the top side of the rolling mill main body 1 so as to roll the supplied copper wire W with a predetermined thickness.

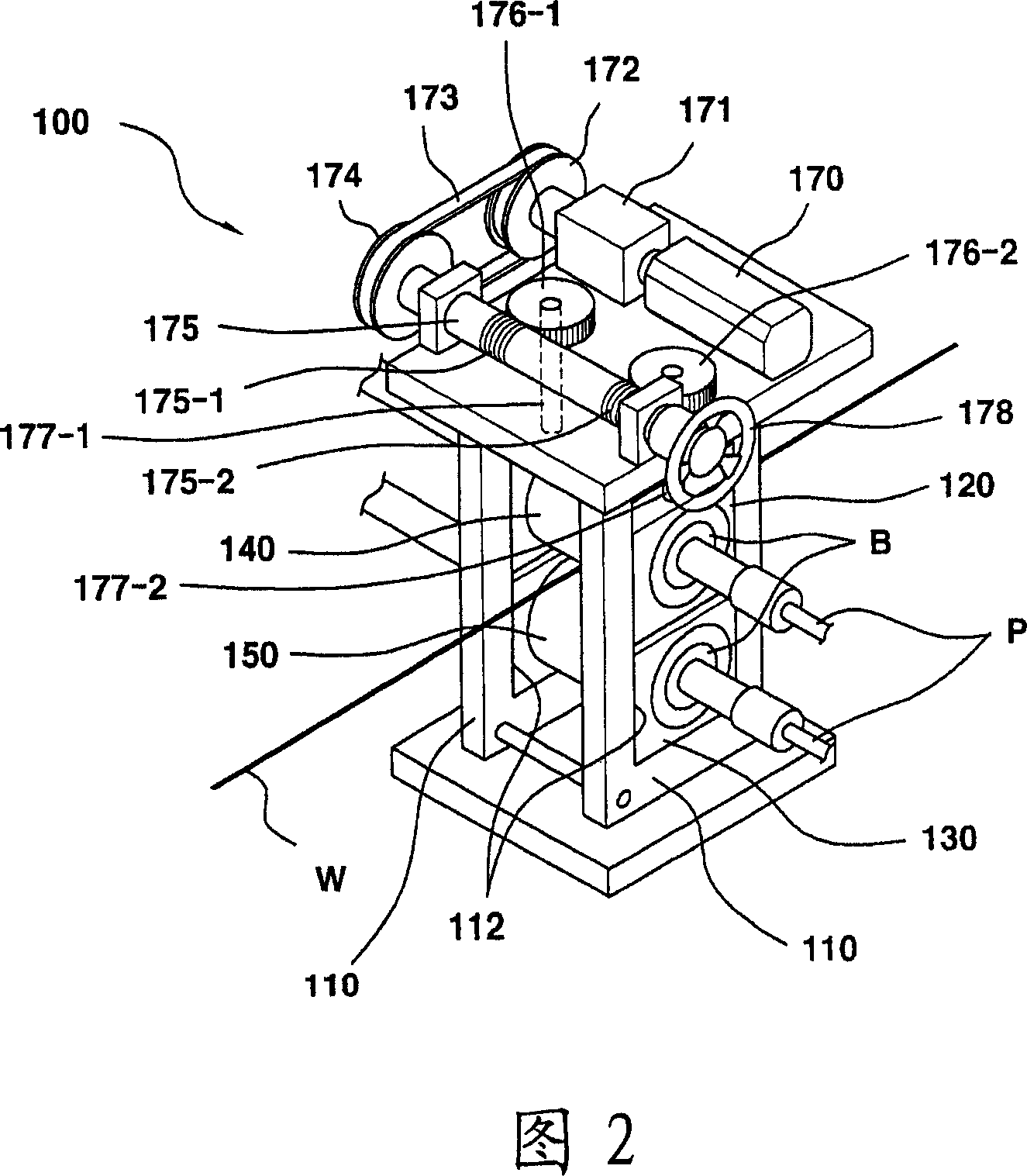

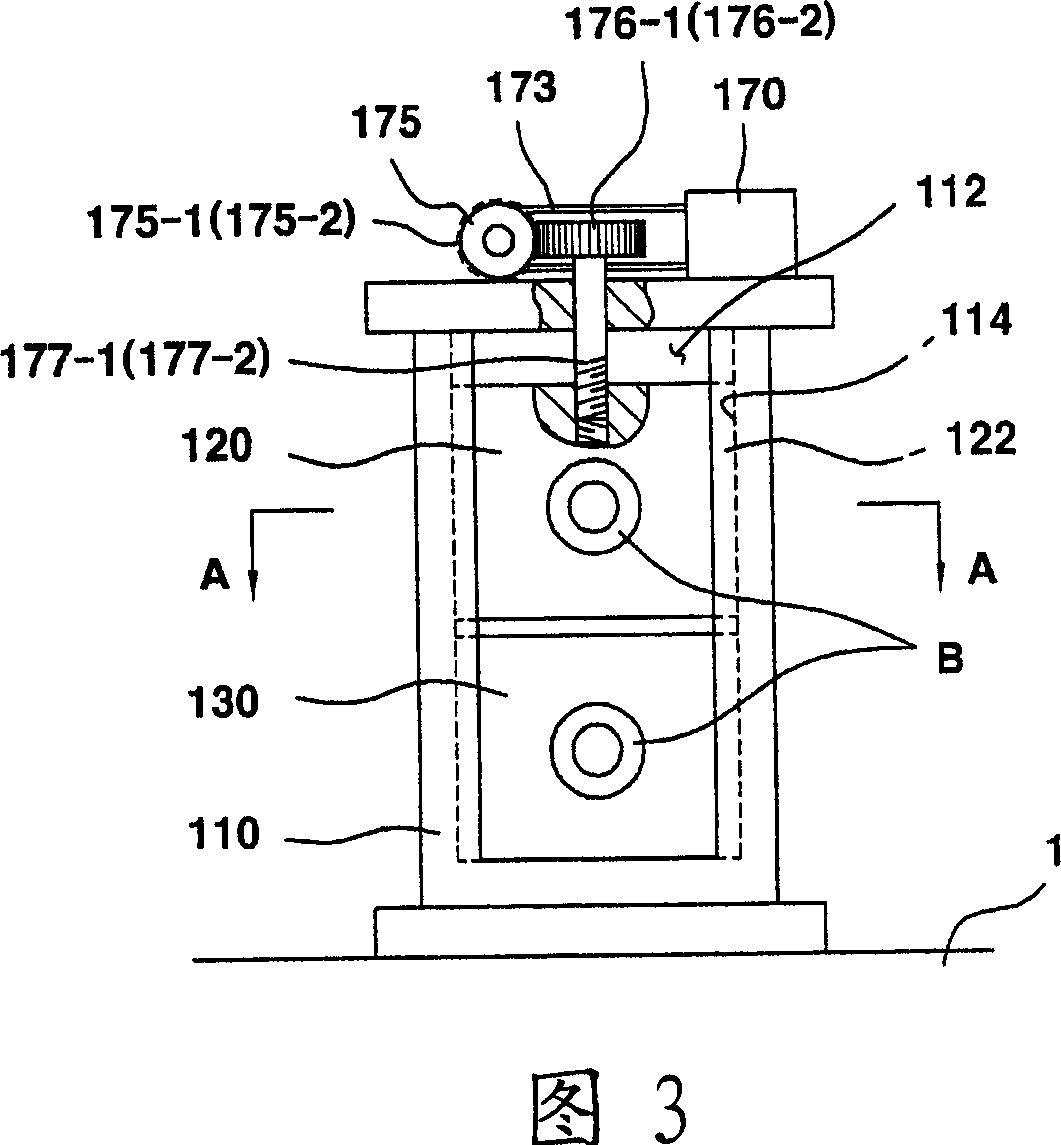

[0018] Describing the configuration of the mill roll 100 in more detail, left and right main frames 110 are mounted on the mill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com