Abnormality detecting apparatus for mold clamping device

A technology for abnormality detection and clamping equipment, which is applied in the field of abnormality detection devices, and can solve the problems of inability to ensure proper movement of the crosshead and movable mold, increased cost of injection molding machines, and inability to detect the crosshead or movable mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

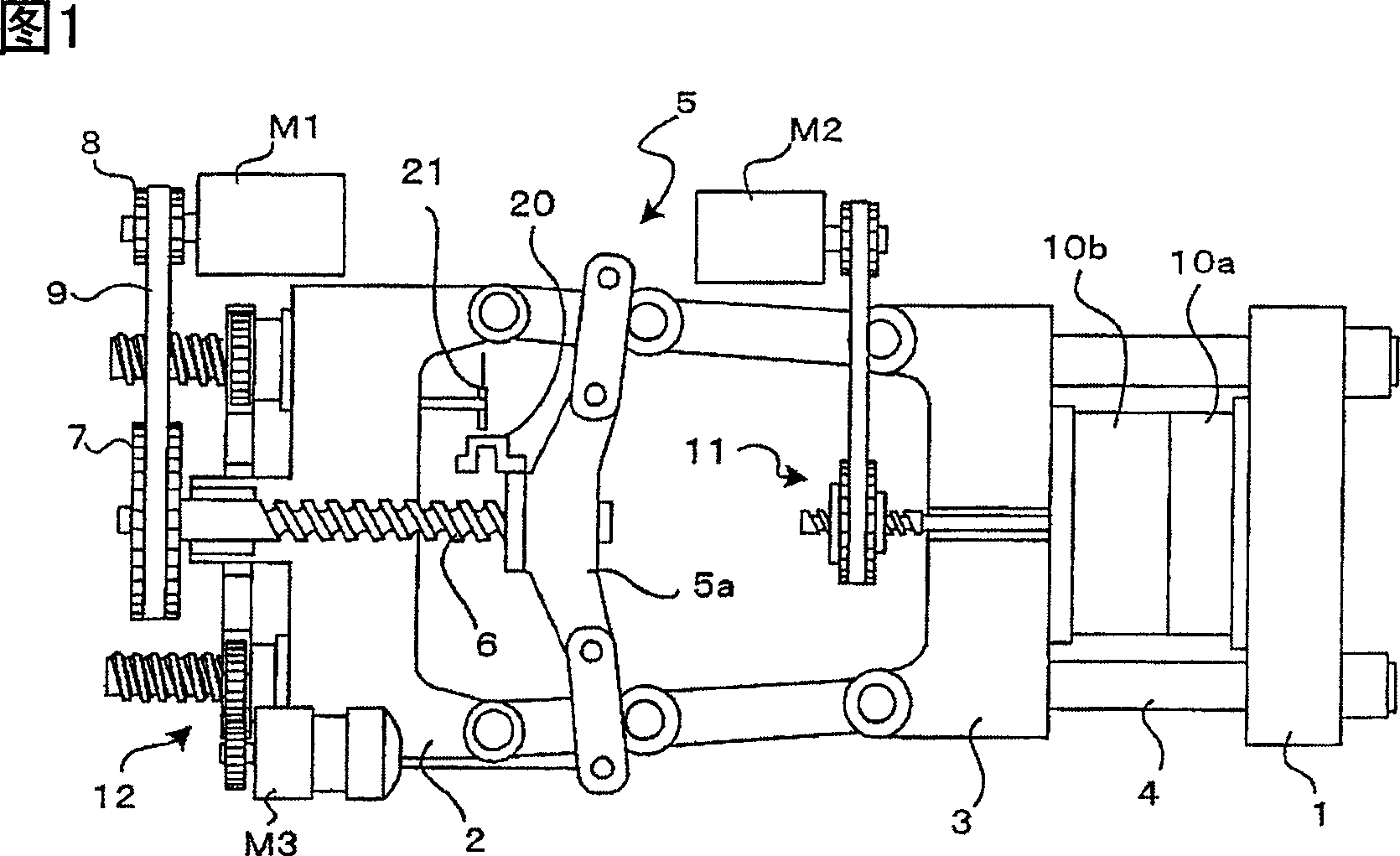

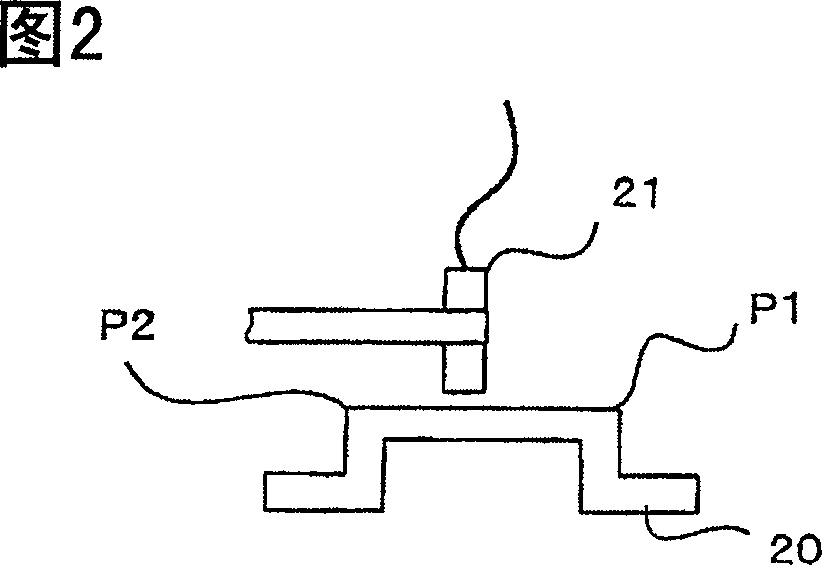

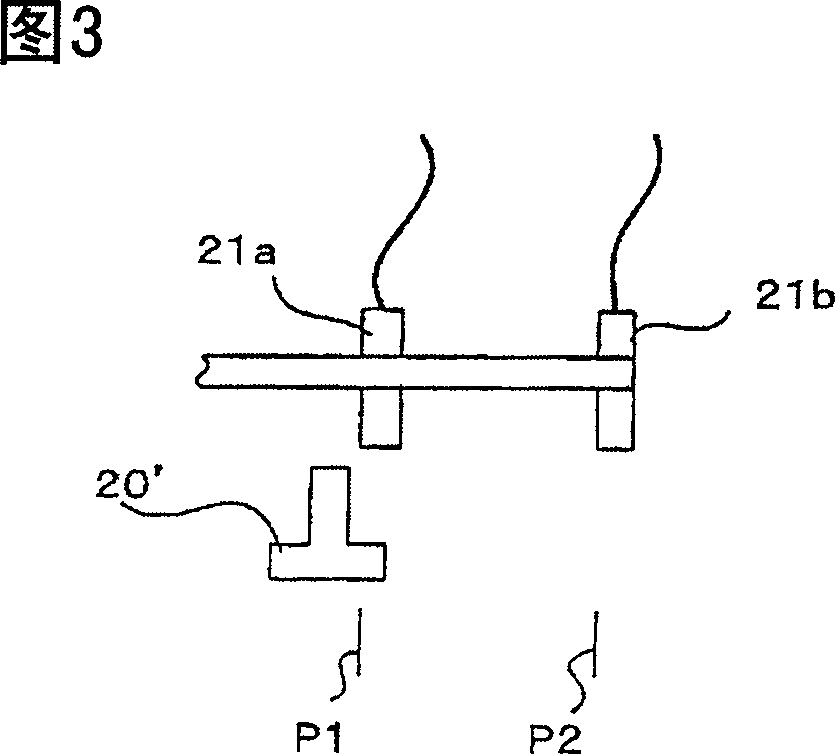

[0021] Fig. 1 is a schematic diagram showing one embodiment of a mold clamping device of an injection molding machine employing the mold clamping device abnormality detecting device of the present invention. The abnormality detecting device of the mold clamping device of the present invention is different from the prior art in that it includes a stopper 20 and a proximity switch 21 added to the abnormality detecting device of the conventional crank lever type mold clamping device.

[0022] The rear platen 2 is connected to a fixed platen 1 fixedly mounted on the base of the injection molding machine by a plurality of connecting rods 4 . The movable platen 3 is guided by the connecting rod 4 and can move freely. The crank lever mechanism 5 is located between the rear press plate 2 and the movable press plate 3, and the crosshead 5a of the crank lever mechanism 5 is installed on the ball nut engaged with the ball screw 6, so that the rotation of the ball screw 6 makes the ball n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com