Decompression gas stripping process

A technology of stripping and oxidation, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as affecting product yield, achieve the effect of inhibiting oxidative decomposition or coking, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

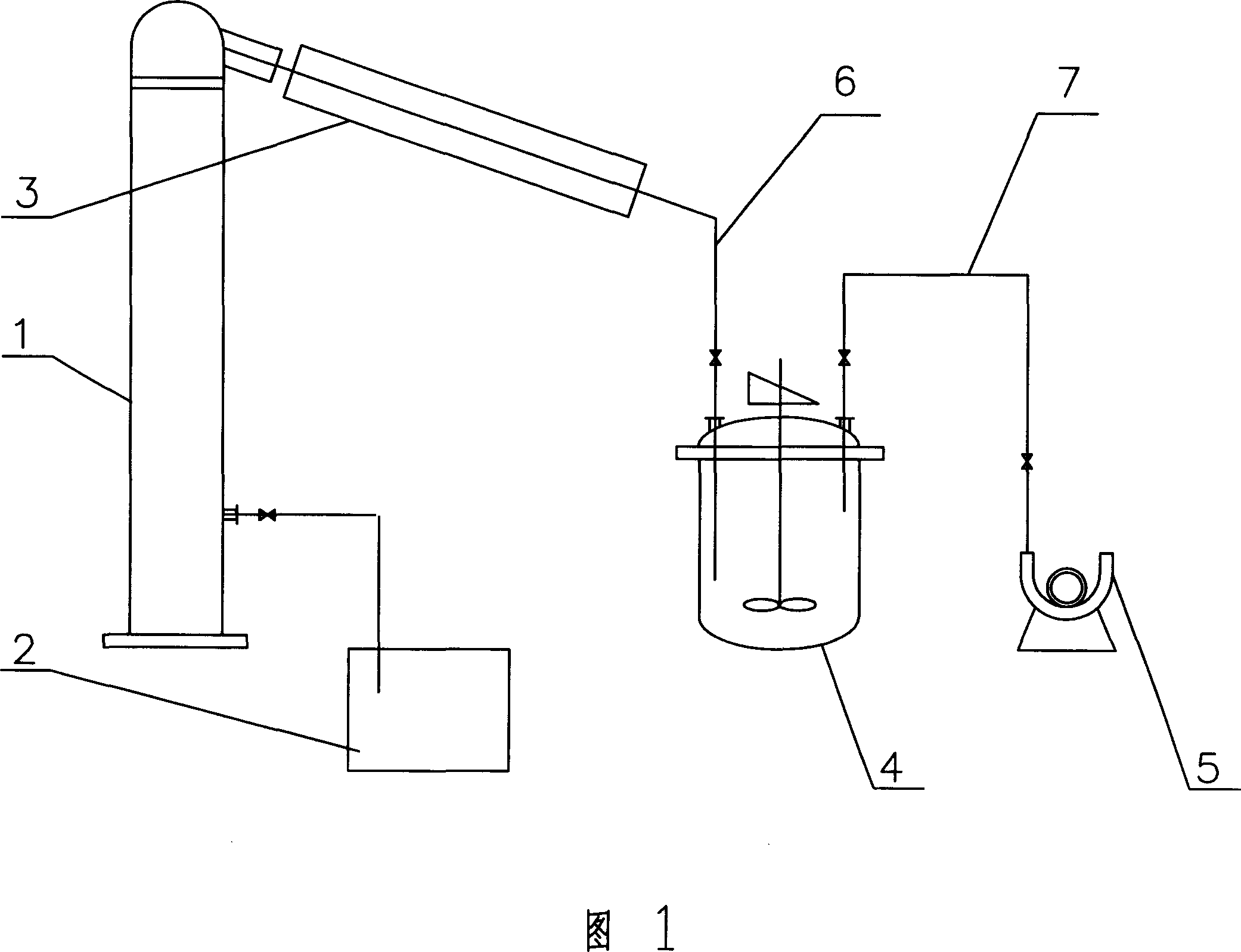

Embodiment 1

[0013] Take oxidized material 890g, measure p-benzoquinone content to be 32.2g. Turn on the vacuum pump 5, adjust the system pressure to be 50mmHg, the temperature at the top of the stripping tower 1 is 40°C, the temperature of the straight tube condenser 3 is 20°C, and the temperature of the crystallization tank 4 is 15°C, and the oxidizing material is evenly added dropwise for stripping. After finishing measuring and stripping, the p-benzoquinone content is 32.1g, and the extraction rate is 99.6%.

[0014] Take 890g of the oxidized material, strip it according to the traditional atmospheric pressure stripping method, and measure the amount of p-benzoquinone to be 28.5g, and the extraction rate is 89%.

Embodiment 2

[0016] Take oxidized material 890g, measure p-benzoquinone content to be 32.2g. Turn on the vacuum pump 5, adjust the system pressure to be 100mmHg, the temperature at the top of the stripping tower 1 is 52°C, the temperature of the straight tube condenser 3 is 22°C, and the temperature of the crystallization tank 4 is 17°C, evenly drop the oxidizing material for stripping, stripping After finishing measuring and stripping, the p-benzoquinone content is 32g, and the extraction rate is 99.3%.

[0017] Take 890g of the oxidized material, strip it according to the traditional atmospheric pressure stripping method, and measure the amount of p-benzoquinone to be 28.5g, and the extraction rate is 89%.

Embodiment 3

[0019] Take oxidized material 890g, measure p-benzoquinone content to be 32.2g. Turn on the vacuum pump 5, adjust the system pressure to 200mmHg, the temperature at the top of the stripping tower 1 is 69°C, the temperature of the straight tube condenser 3 is 52°C, and the temperature of the crystallization tank 4 is 22°C, and evenly add the oxidizing material dropwise for stripping. After finishing measuring and stripping, the p-benzoquinone content is 31.8g, and the extraction rate is 98.7%.

[0020] Take 890g of the oxidized material, strip it according to the traditional atmospheric pressure stripping method, and measure the amount of p-benzoquinone to be 28.5g, and the extraction rate is 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com