Step down product accumulation system

A product, accumulator technology used in conveyor objects, transportation and packaging, conveyors, etc., to solve problems such as product misalignment, interruption of system operation, and overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

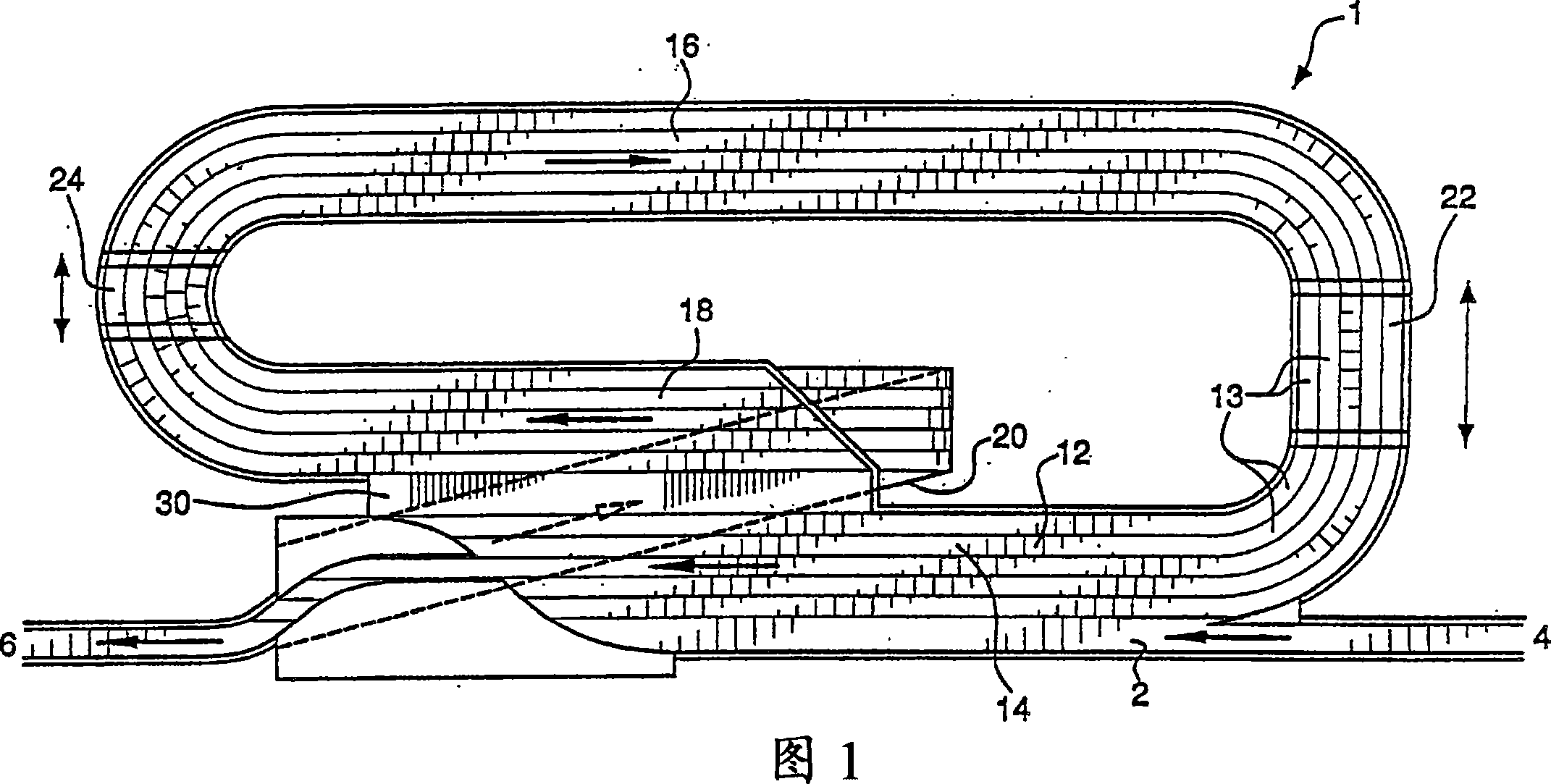

[0024] As shown in FIG. 1 , the product conveying system and accumulation system 1 of the present invention includes a conveyor belt 2 configured to move products from an upstream position or location indicated at 4 to a downstream location or location indicated at 6 .

[0025] The system 1 also includes a conveyor belt 12, which may consist of interlocking segments 13 as known in the art. The conveyor belt 12 includes product path sections 14 and 16 and an accumulator section 18 . All these sections form a single continuous loop conveyor belt completed by section 20 of conveyor belt 12 . Section 20 underlies accumulator section 18 and wraps accumulator section 18 from top to bottom. The direction of travel of the conveyor belts 2 and 12 is depicted by the belt direction arrows shown in FIG. 1 .

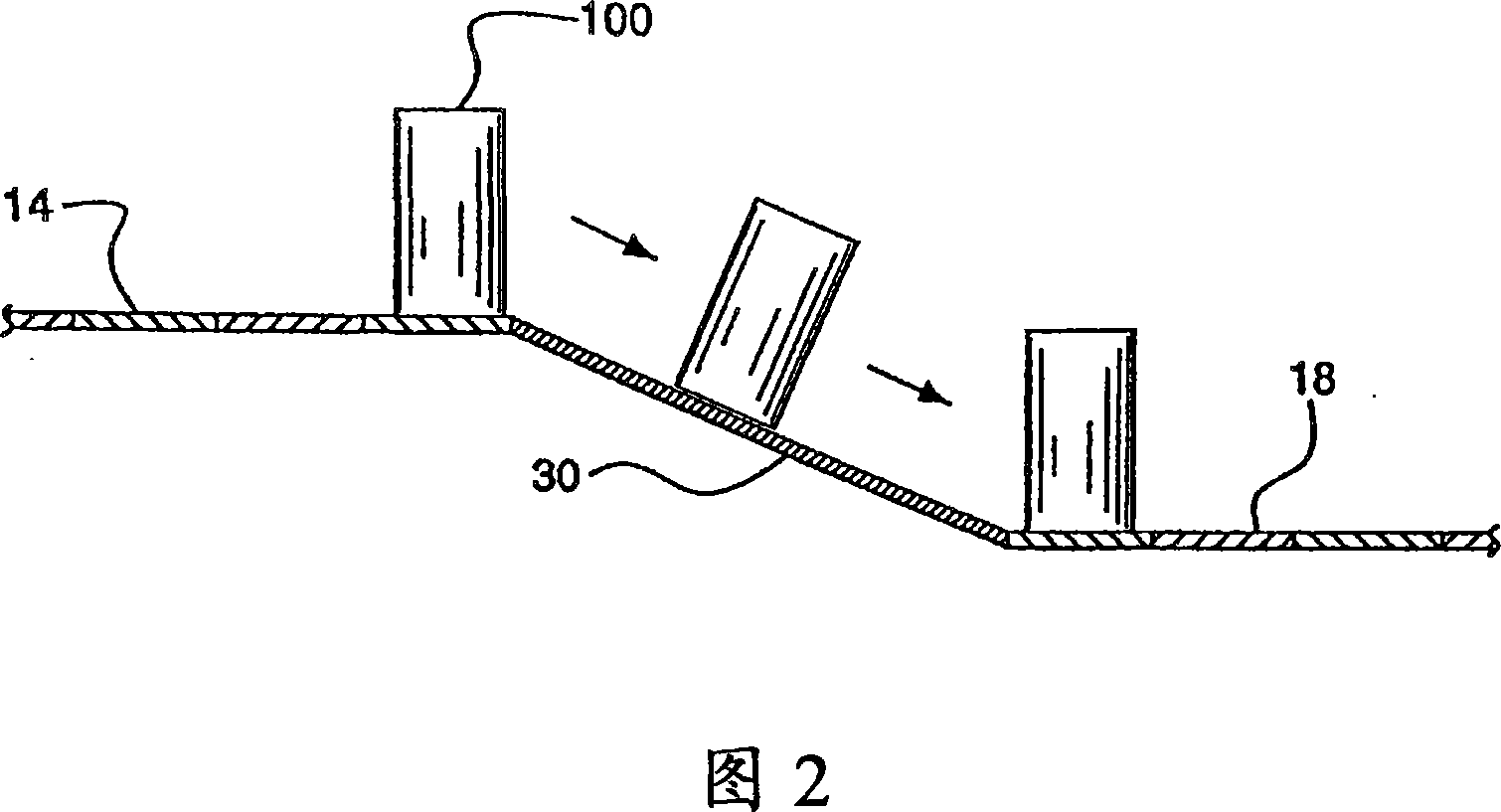

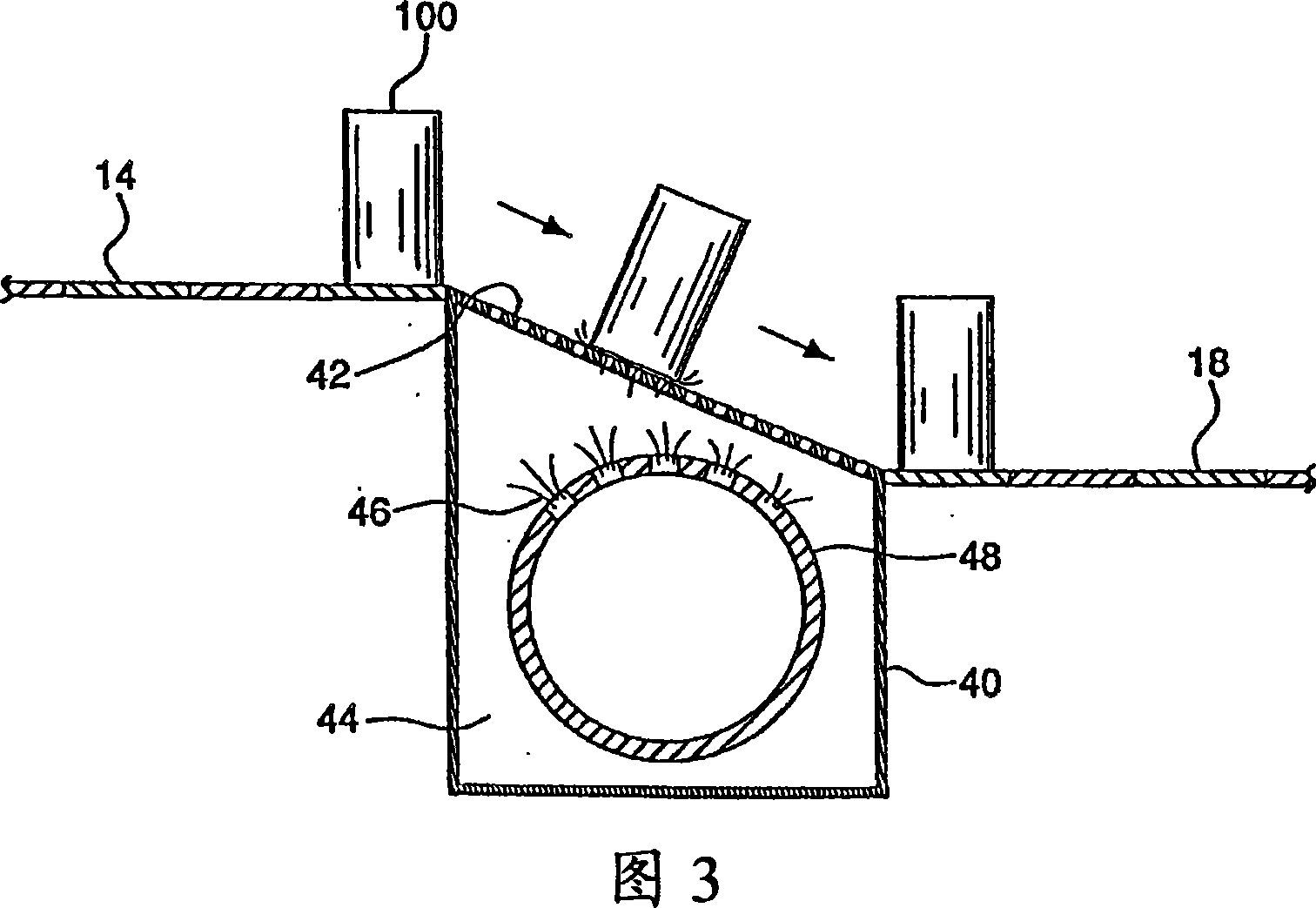

[0026] As shown in Figures 1 and 2, the product path section 14 lies in a higher, but still parallel, transverse plane than the transverse plane in which the accumulator section 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com