All-tailings concentrating adglutinate new process

A concentrated gel and new process technology, which is applied in the new process of tailings concentration and cementation, can solve the problems of surface discharge of mine tailings, hazards to the living environment, life and property safety, and increase in underground gobs, achieving efficient concentration and convenient Effects of organization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

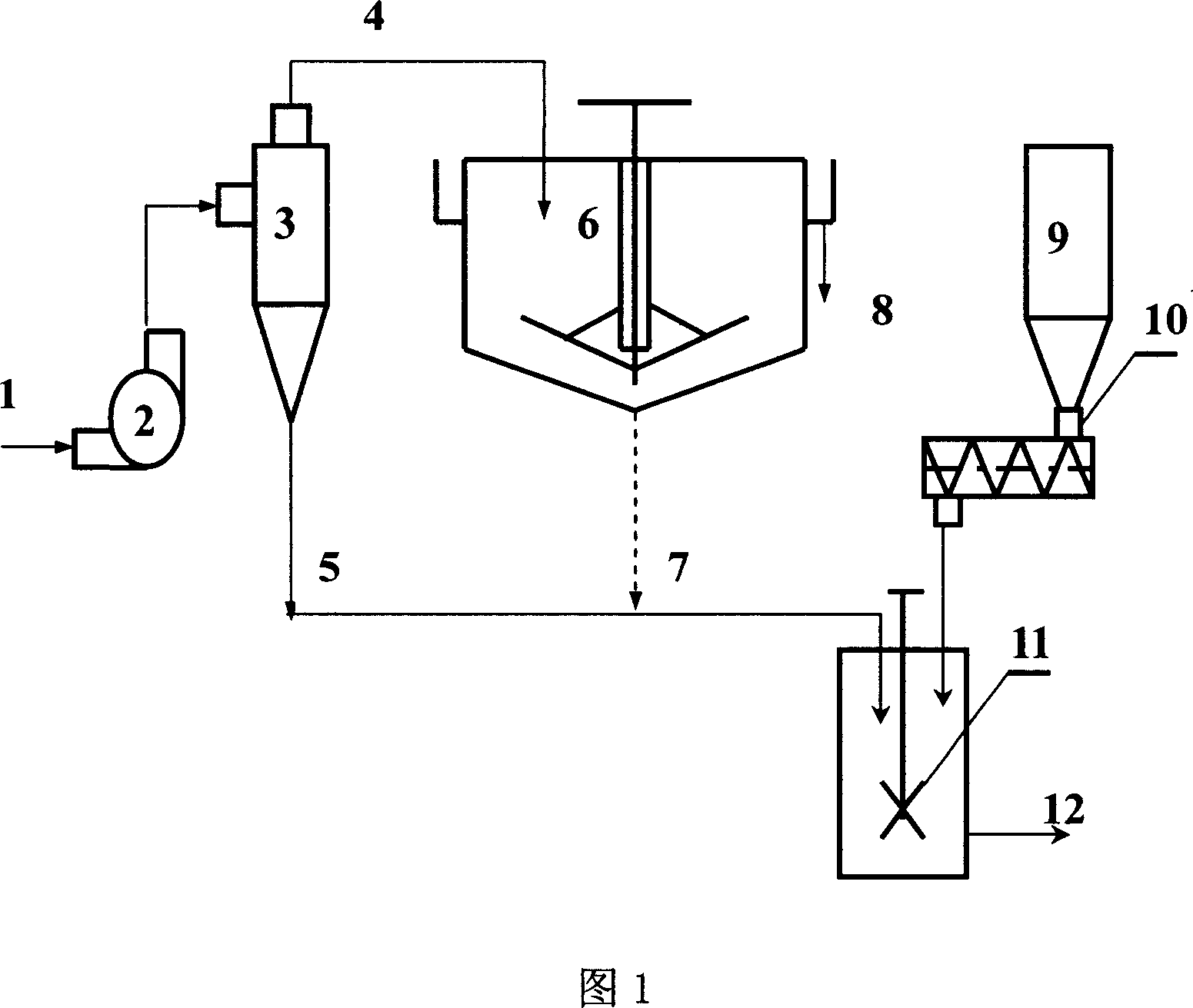

Embodiment 1

[0011] Example 1, a graded concentration cementation test was carried out using the magnetic separation tailings of a certain mine in Hebei as raw materials. The concentration of the tailings is about 10%, and the content of less than 200 mesh accounts for 84%. The test uses a Φ100mm concentrated hydrocyclone. When the ore feeding pressure is 0.15MPa and the sand outlet is 8mm, the yield rate can be 75.14%, and the concentration of the hydrocyclone is 69.15%. The yield rate is 24.86%. The overflow of the cyclone with a concentration of 2.79% enters the thickener. When the amount of polyacrylamide (6 million molecular weight) flocculant is 20g / t (according to the amount of dry mineral), the return water of the thickener can be clear water, and when the underflow When the discharge concentration is 34.82%, the cyclone sand settling and thickener bottom flow are combined to obtain a final tailings concentration of 55.54%. When the amount of high-water single slurry cement is 10-12...

Embodiment 2

[0012] In Example 2, a concentration test was carried out using flotation tailings from a certain mine in Shandong as raw materials. The concentration of the tailings was about 35%, and the content of less than 200 mesh accounted for 50%. The test uses a Φ250mm concentrated hydrocyclone. When the ore feeding pressure is 0.12MPa and the sand outlet is 35mm, the yield rate can be 65%, the concentration is 70%, and the yield rate is 35%. The overflow of the cyclone with a concentration of 18% enters the thickener. When the amount of polyacrylamide (6 million molecular weight) flocculant is 10g / t (according to the amount of dry mineral), the overflow of the thickener can be realized as clean water. When the underflow When the discharge concentration is 45%, the cyclone grit and thickener underflow are combined to obtain a final tailings concentration of 58%. When the amount of high-water single slurry cement is 8-10% of the tailings, The strength of the cemented sample can reach m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com