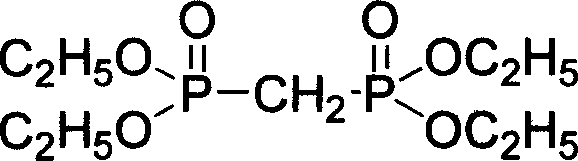

Method for preparing methodlene tetraethyl diphosphate

A technology of tetraethyl methylene diphosphonate and triethyl phosphite, which is applied in the field of preparing tetraethyl methylene diphosphonate, can solve the problems of low reaction yield and achieve high reaction yield and reaction stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Measure 4ml (9.92g) of dibromomethane and mix with 30ml (29.05g) of triethyl phosphite. The mixture was heated to 100°C under reflux for 30 minutes, and then heated to 175°C for 22 hours. During the reaction, the by-product bromoethane is steamed out, and the unnecessary reactants and by-products are steamed by distillation under reduced pressure, and finally, distillation under reduced pressure obtains 13.6 g of product tetraethyl methylene diphosphonate (content reaches 95.4%), and the yield was 79.0%.

Embodiment 2

[0015] Measure 8 ml (19.8 g) of dibromomethane and mix with 60 ml (58.1 g) of triethyl phosphite. The mixture was heated to 90°C under reflux for 35 minutes, and then heated to 185°C for 18 hours. During the reaction, the by-product bromoethane was steamed out, and the unnecessary reactants and by-products were steamed by distillation under reduced pressure, and finally the product was distilled under reduced pressure to obtain 27.8 g (content of 95.2%) of tetraethyl methylene diphosphonate. was 80.8%.

Embodiment 3

[0017] Measure 16 ml (39.6 g) of dibromomethane and mix with 100 ml (97.4 g) of triethyl phosphite. The mixture was heated to 85° C. for reflux reaction for 40 minutes, and then heated to 190° C. for 20 hours. During the reaction, the by-product bromoethane was steamed out, and the unnecessary reactants and by-products were steamed by distillation under reduced pressure, and finally the product was distilled under reduced pressure to obtain 53.8 g of tetraethyl methylene diphosphonate (the content reached 95.8%), and the yield was 78.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com