Gas pipeline assembly for gas type drying machine

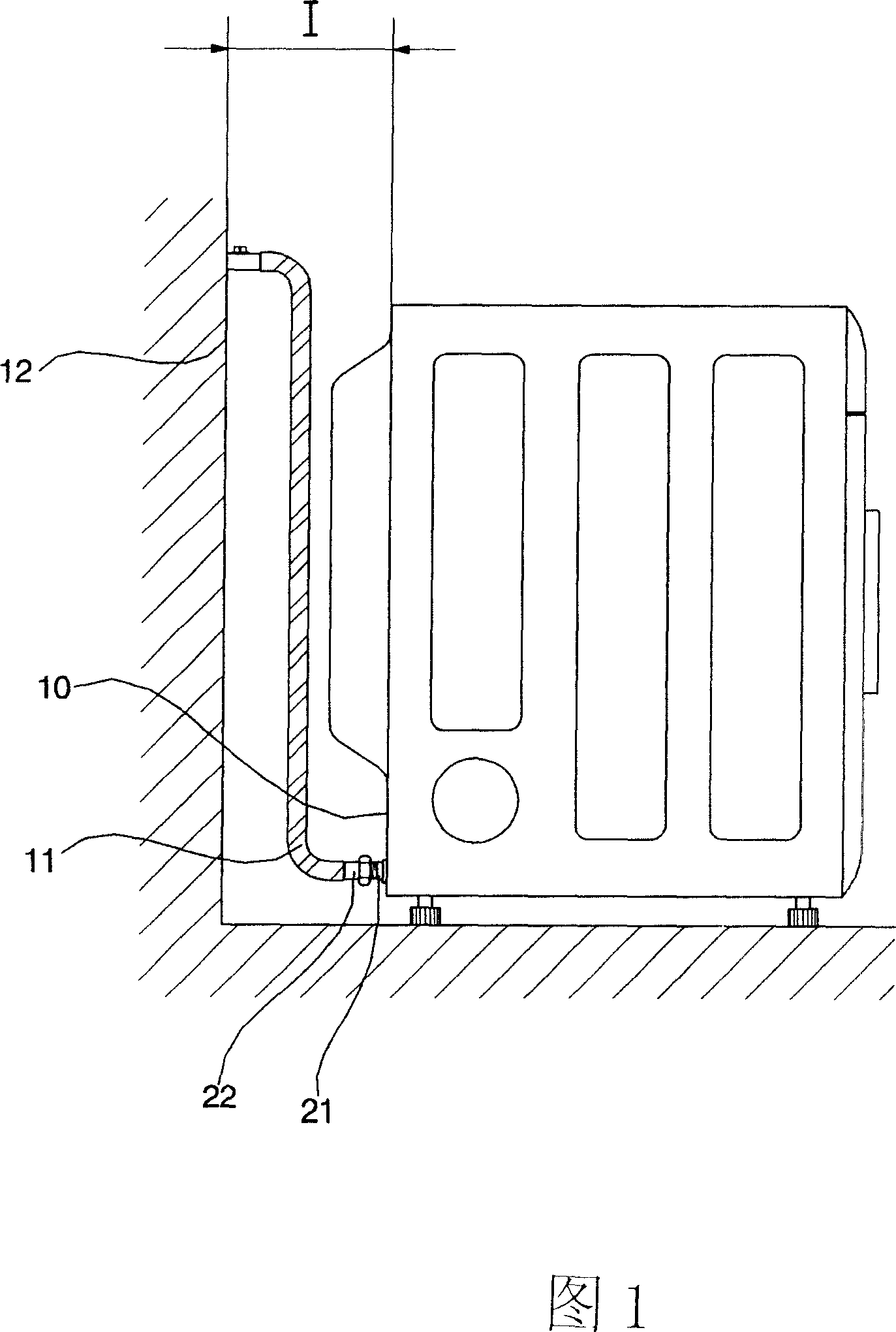

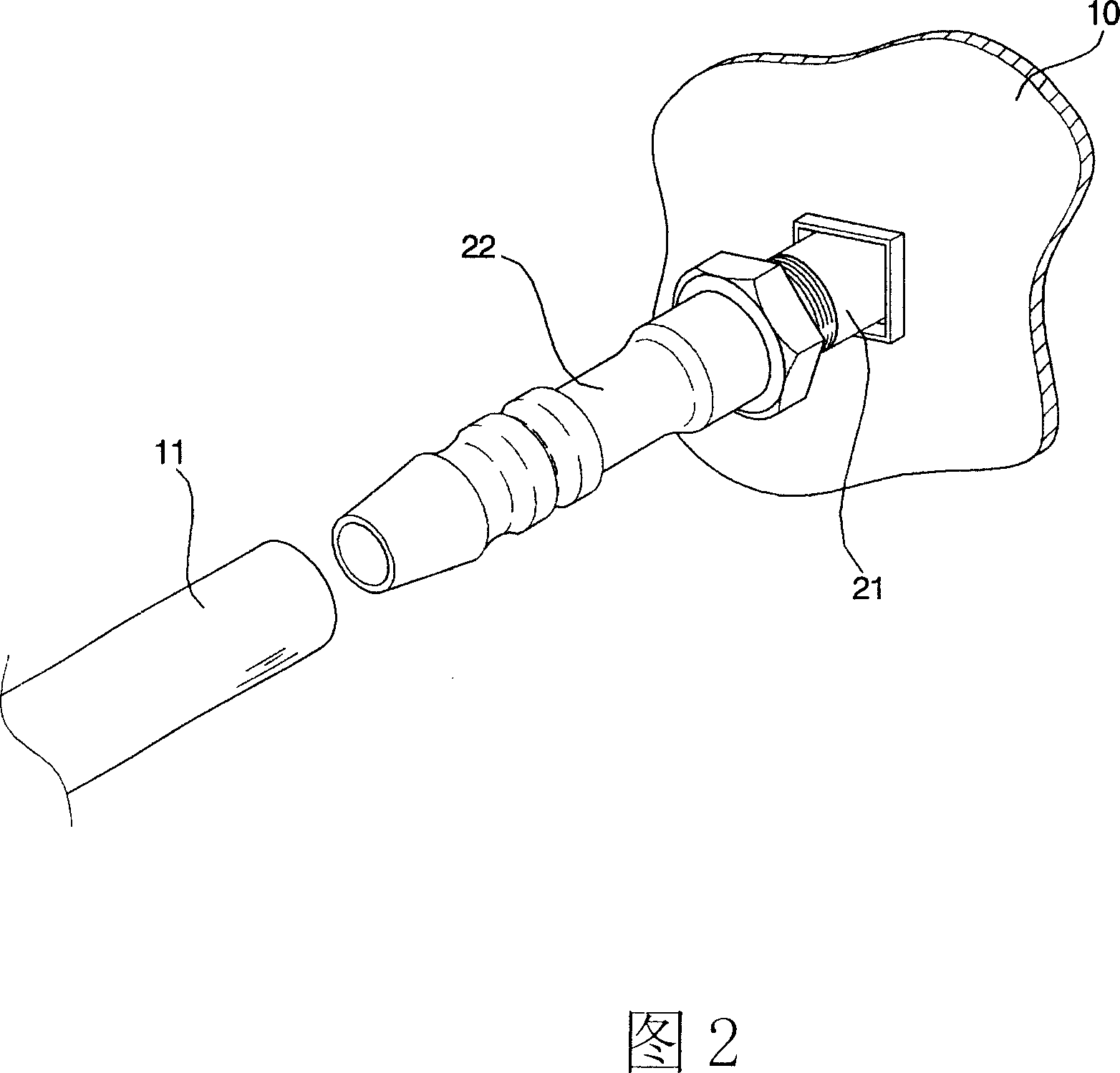

A technology for gas pipelines and dryers, which is applied to household clothes dryers, pipes/pipe joints/pipes, pass-through components, etc., can solve problems such as falling off, protruding gas pipeline components, and waste of dryer space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

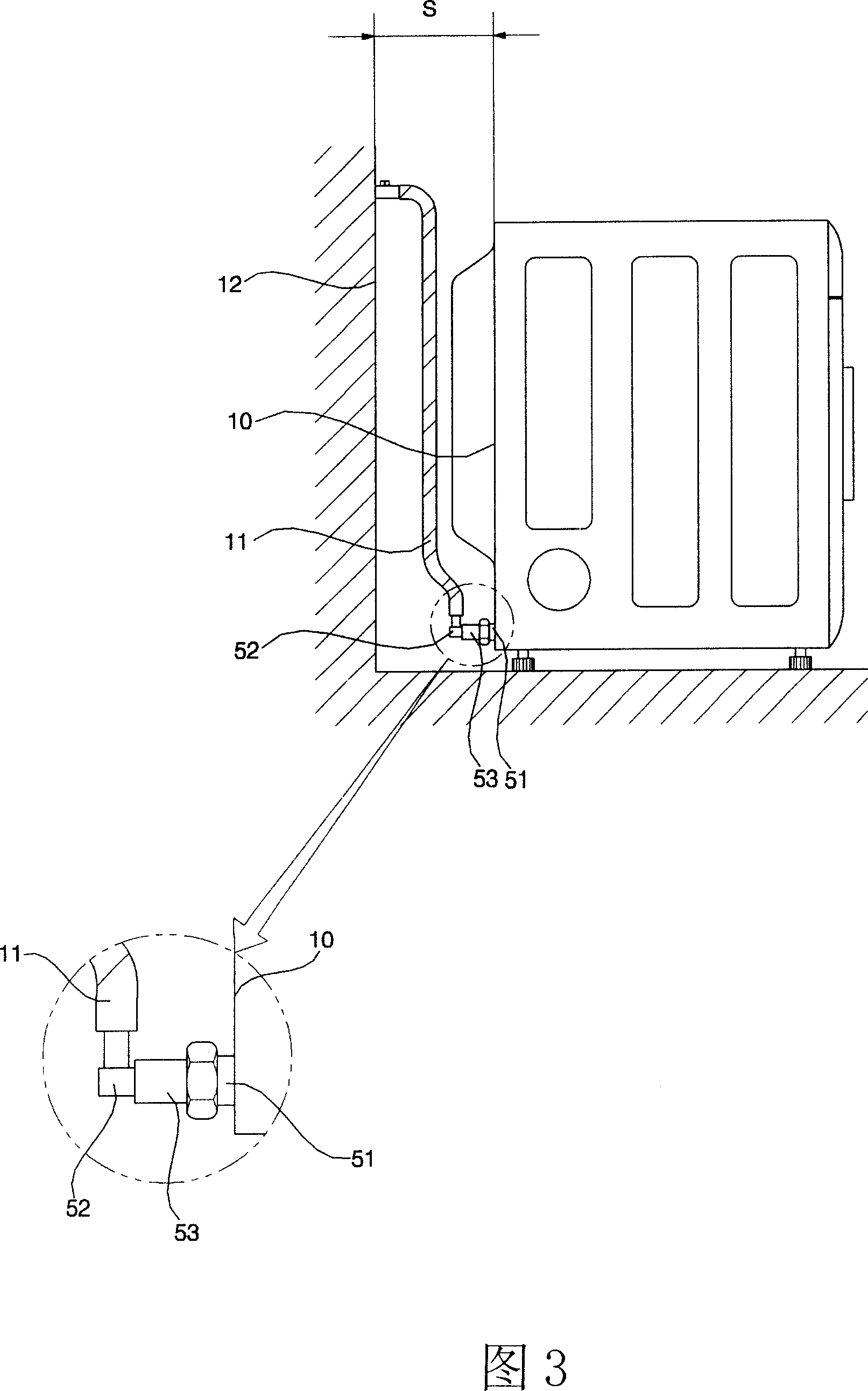

[0030] As shown in Figure 3, the gas pipeline assembly in the embodiment example of the present invention is made up of the following parts, namely the cabinet 10 that forms the appearance of gas-fired dryer; The gas pipeline 51 that protrudes from one side of above-mentioned cabinet 10; The gas hose 11; the nipples 52, 53 for connecting the gas pipeline 51 and the gas hose 11.

[0031] The nipples 52 and 53 are composed of a rotating part 52 and a supporting part 53 supporting the rotating part 52 and connected with the gas pipeline 51 . The above-mentioned rotating member 52 is formed by bending, and the above-mentioned rotating member 52 can rotate about the above-mentioned gas pipe 51 as an axis.

[0032] In this way, the dryer connected with the gas pipeline assembly of the gas-fired dryer of the present invention should be separated from the wall 12 opposite to the protruding part of the gas pipeline assembly by a certain distance S. At this time, the above-mentioned ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com