Electromechanical part of rotary compressor

A rotary compressor and mechanical technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit static parts, magnetic circuit shape/style/structure, etc., can solve the problem of low speed and maximum torque, unreasonable magnetic field distribution, and inefficiency Achieving optimality and other issues, to achieve optimal efficiency, reasonable distribution of the magnetic field, and the effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

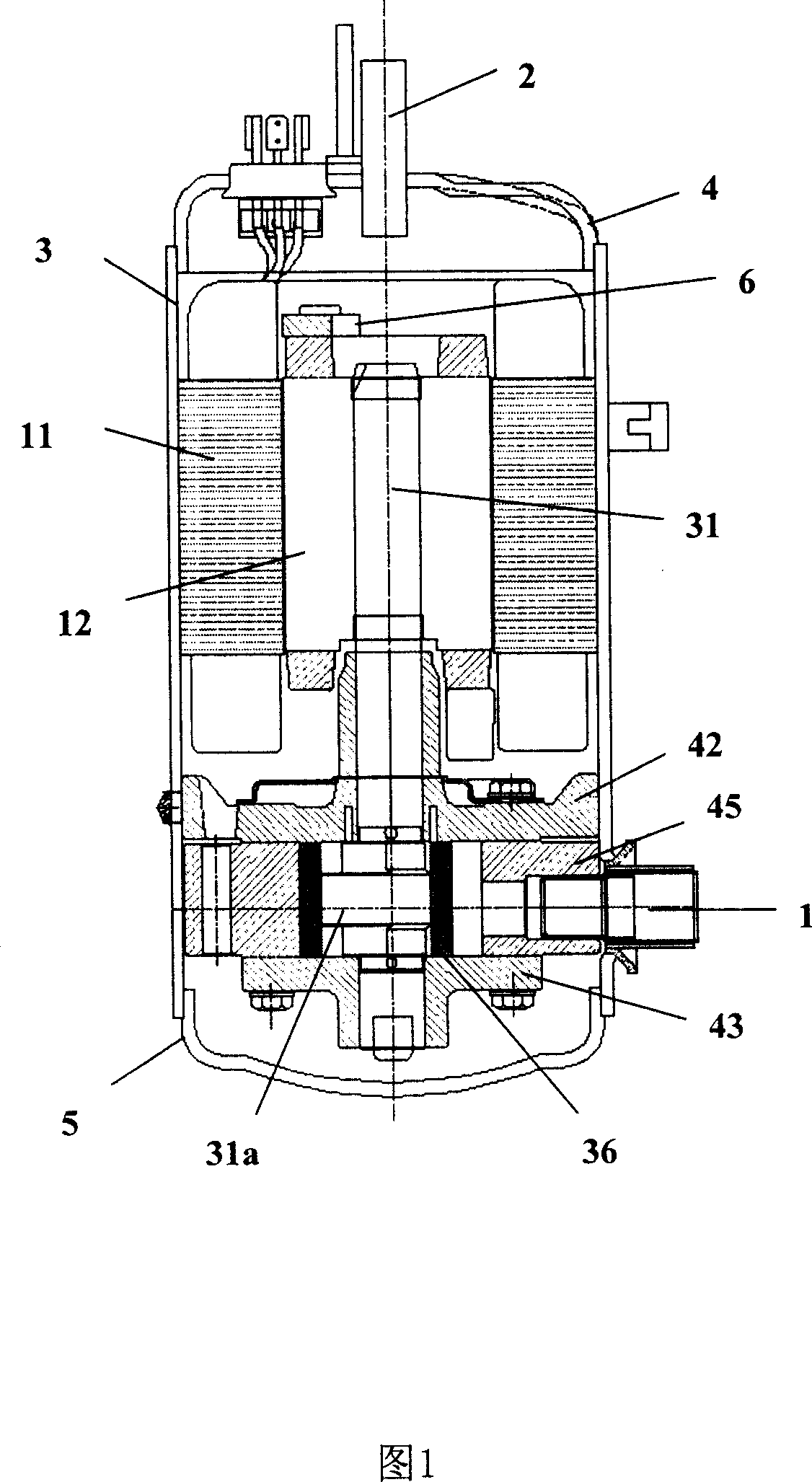

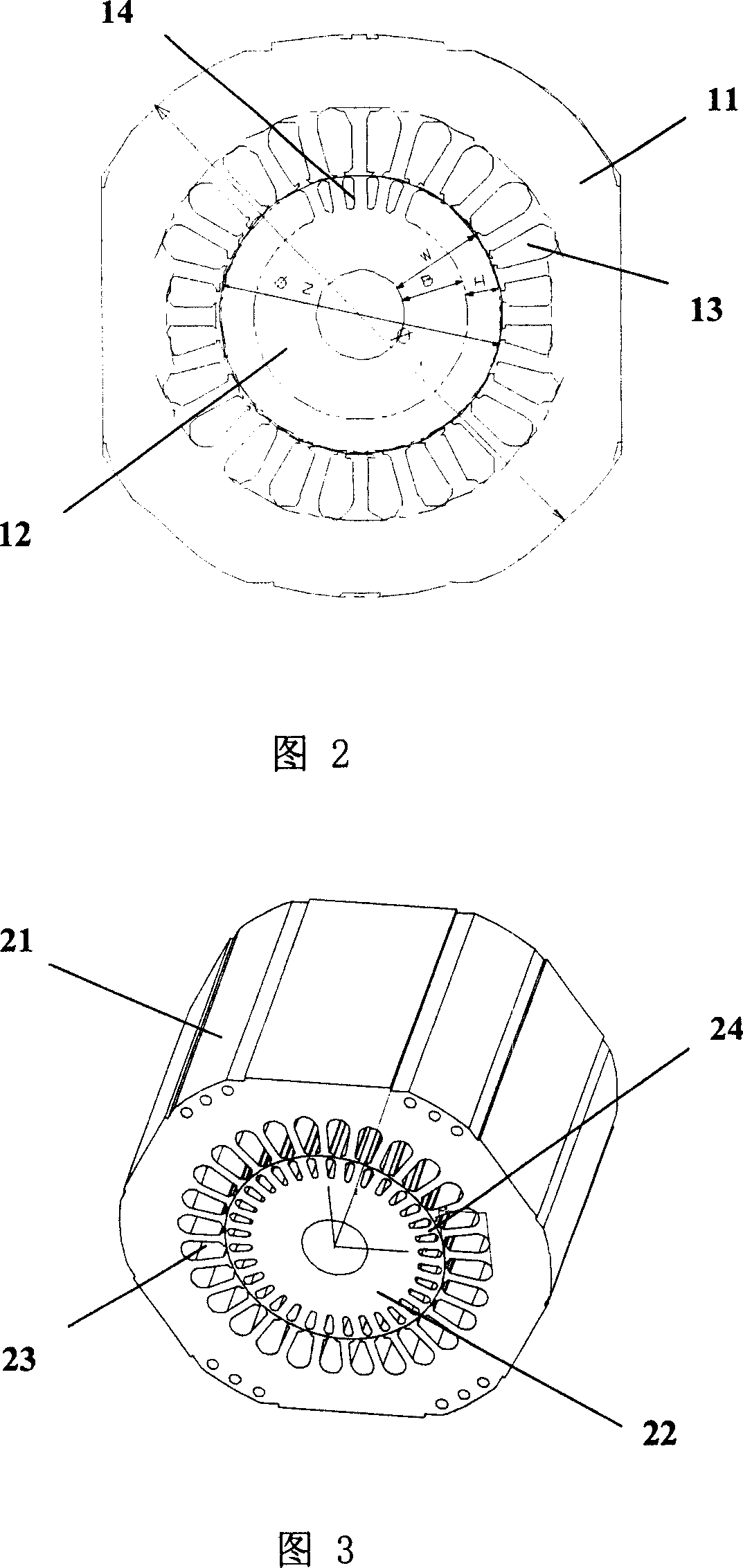

[0011] As shown in Fig. 3 and Fig. 1, the electromechanical part of the rotary compressor provided by the present invention is mainly composed of a stator 21 fixed on the inner wall of the cylindrical shell 3 and a motor which is located at the center of the stator 21 and can pass between the stator 21. The rotor 22 is composed of a rotor 22 that rotates by electromagnetic action; the stator 21 is in a tubular structure, and 28 stator slots 23 are formed in radial depressions on its inner circumference; A plurality of rotor slots 24, the height of each rotor slot 24 is 11mm. The number of rotor slots 24 on the rotor 22 is the same as that of the prior art. When the rotary compressor provided by the present invention is in operation, the rotor 22 located at the upper center of the airtight container will rotate at a high speed through the electromagnetic interaction with the stator 21, and at the same time drive the crankshaft 31 that runs through its center and the lower part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com