Patents

Literature

32results about How to "Increased maximum torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano silicon dioxide with grafting of polyisoprene on surface, preparation method and application thereof

The invention provides a nano silicon dioxide with grafting of polyisoprene on the surface, a preparation method and an application thereof. The preparation method comprises the steps of dispersing the nano silicon dioxide in a solvent, then adding an RAFT (Reversible Addition Fragmentation chain Transfer) reagent with carboxyl groups, a dewatering agent and a catalyst for reaction to obtain nano silicon dioxide capable of initiating RAFT polymerization of isoprene monomers; then mixing with the isoprene monomers for reaction to obtain the nano silicon dioxide with grafting of the polyisoprene on the surface. The nano silicon dioxide particles can improve the blending effect of different rubbers or the rubbers and plastic molecules in a more-effective manner by utilizing the compatibility of the grafted polyisoprene and a base material so as to provide a better basis for exerting the synergistic property of different components in a more-effective manner.

Owner:安徽凯得兴汽车零部件科技有限公司

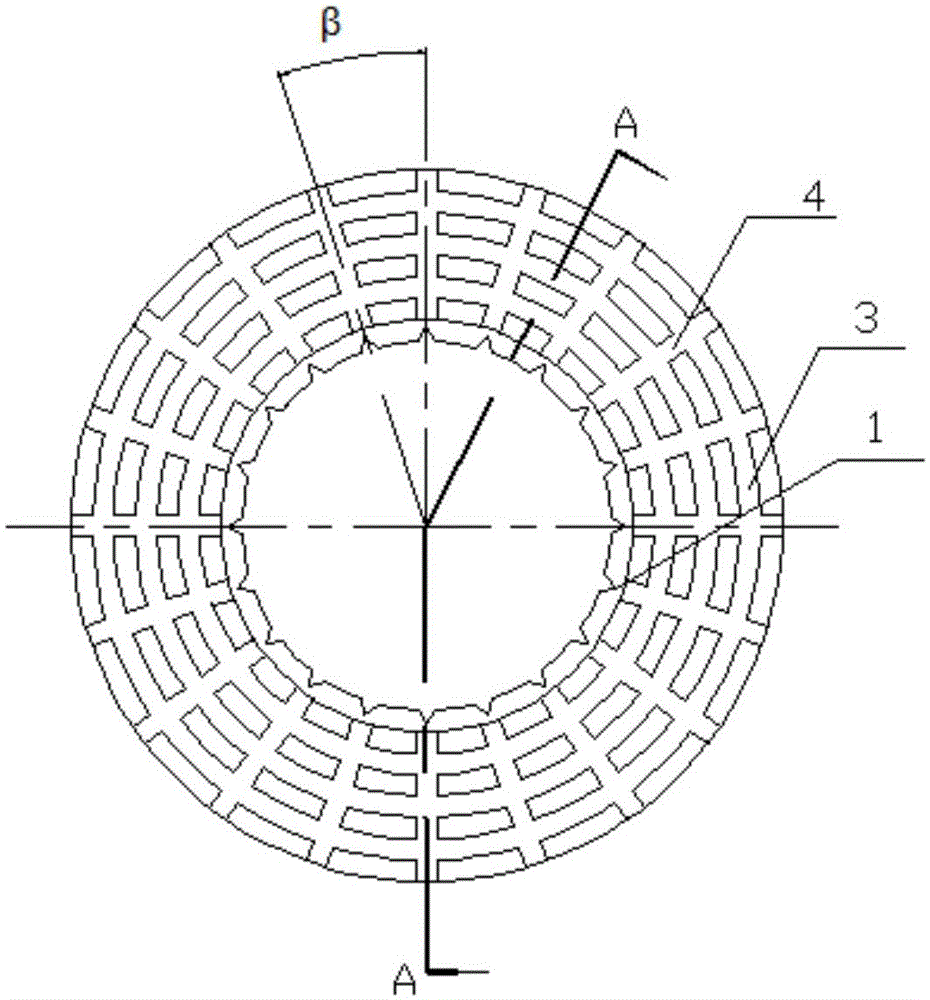

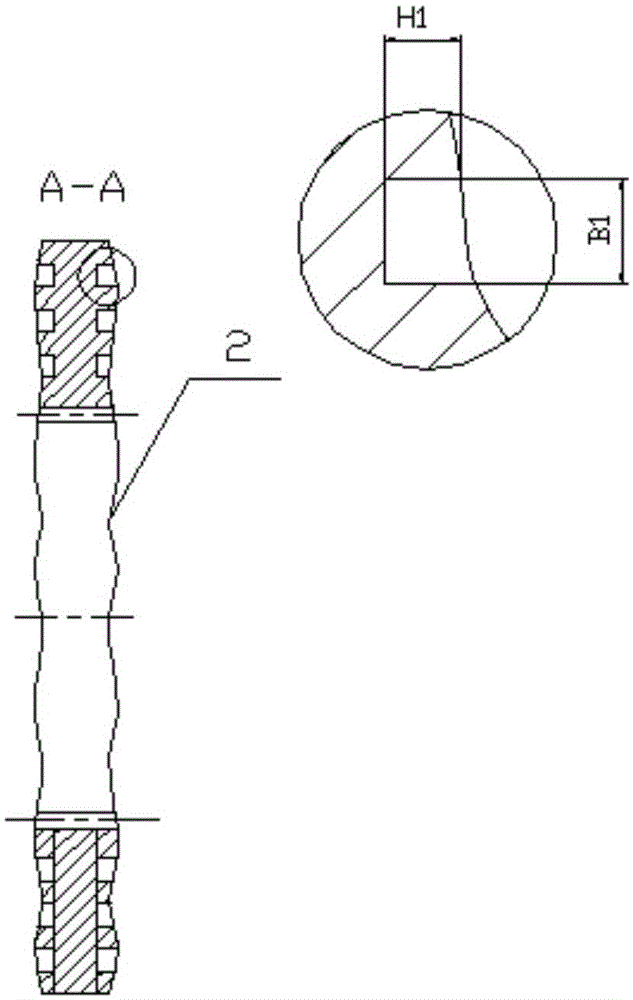

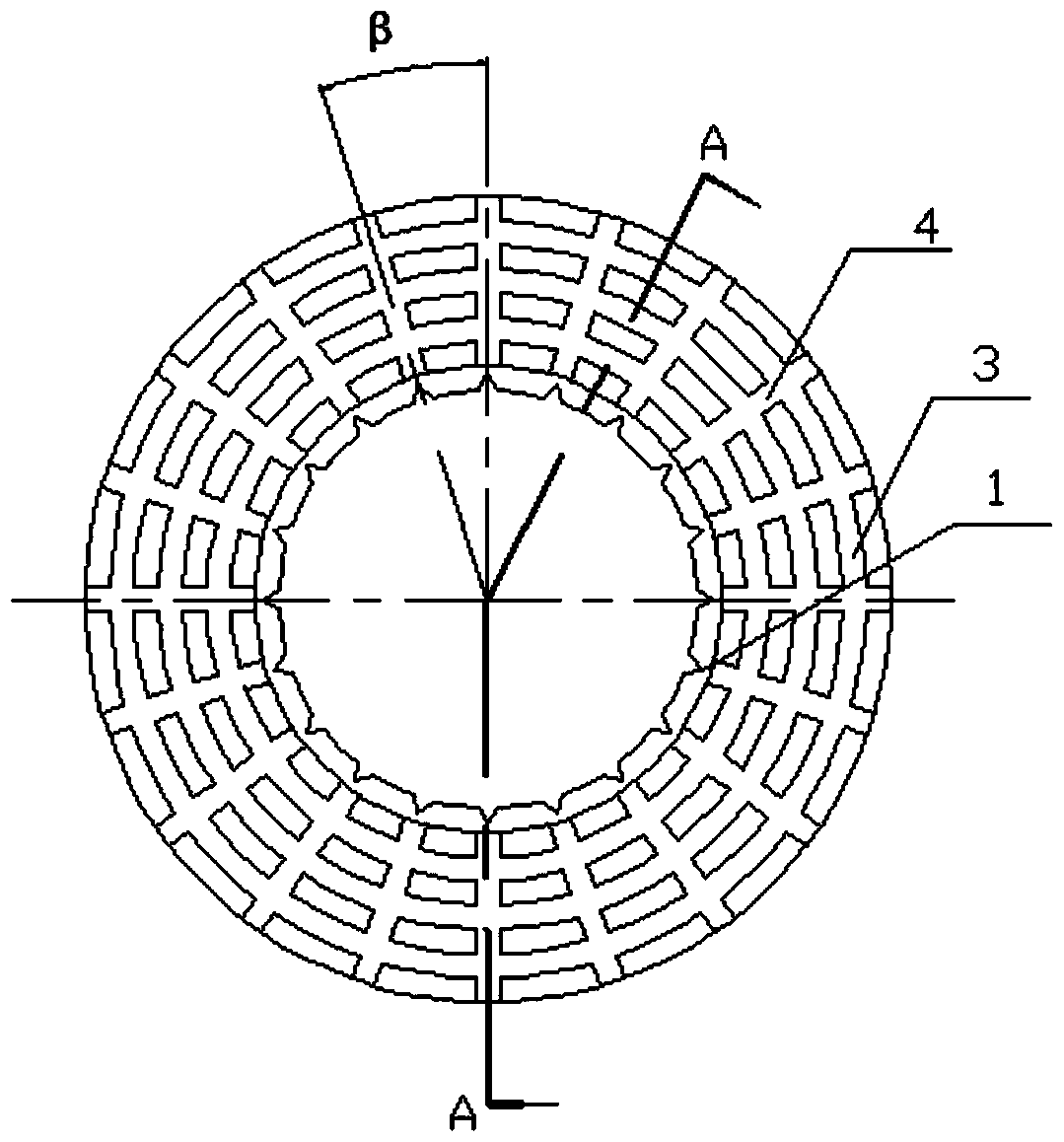

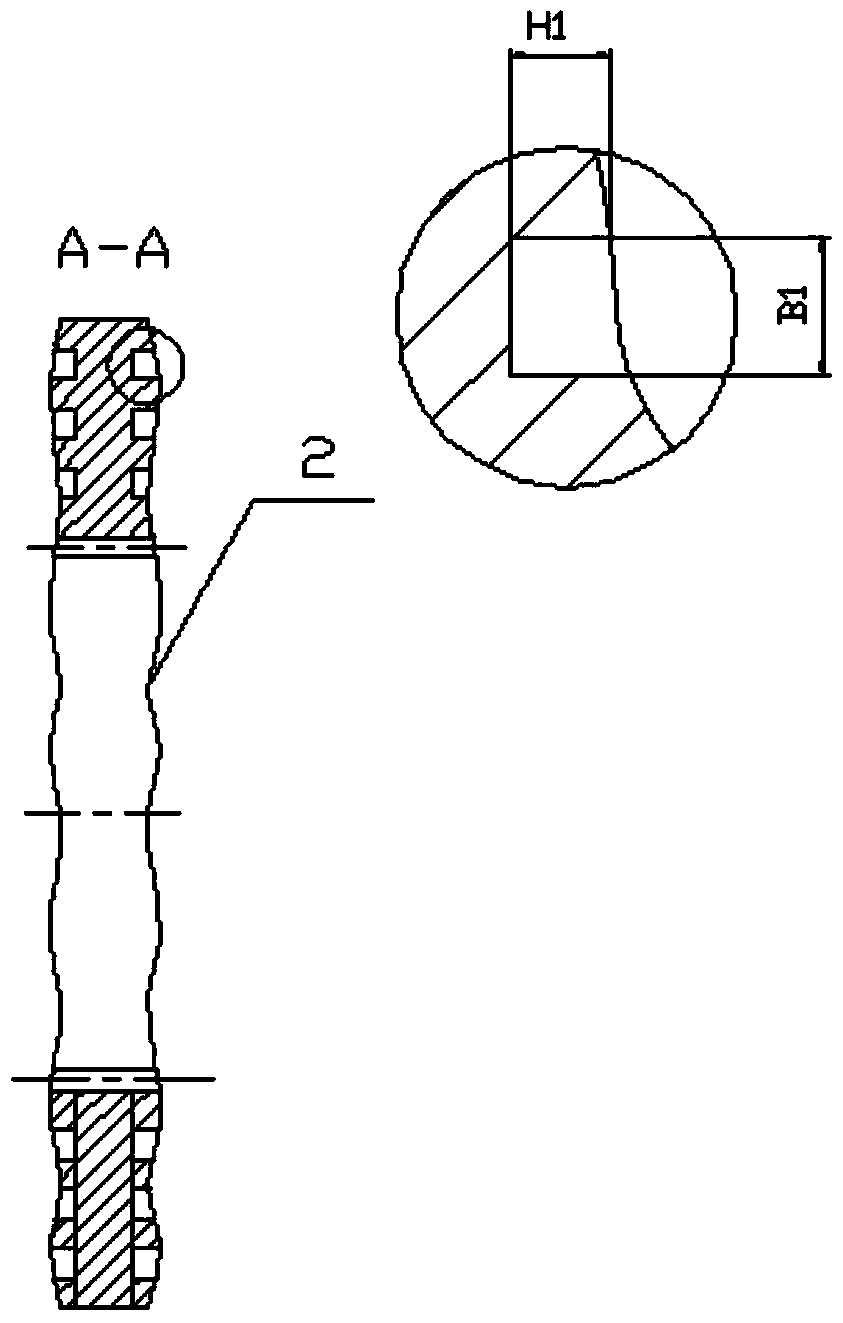

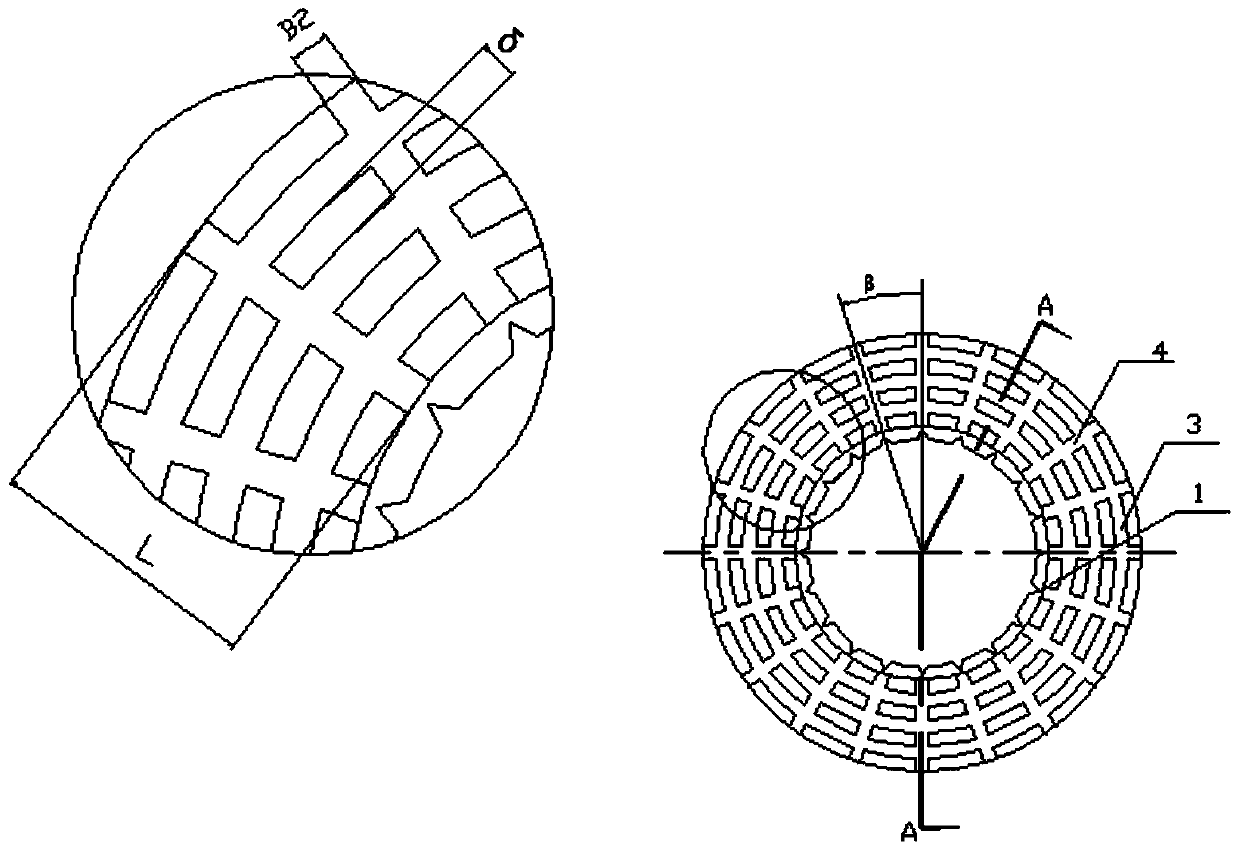

Anti-deformation dual disc of hydro-viscous speed regulating clutch

InactiveCN105041911AStable jobIncrease contact areaFluid clutchesFriction liningViscous liquidWork performance

The invention provides an anti-deformation dual disc of a hydro-viscous speed regulating clutch. The dual disc is a ring-shaped steel disc with the thickness being 2 to 5mm; and spline teeth are arranged on the inner ring or the outer ring of the ring-shaped steel disc. The anti-deformation dual disc is characterized in that the working surface of the dual disc is wavy, is uniformly provided with concentric ring-shaped grooves along the radial direction and is uniformly provided with radial rectangular grooves along the circumferential direction. The anti-deformation dual disc provided by the invention has the advantages that the radiating condition of friction pairs is improved, the film-forming capability and the kinetic-pressure bearing capability of viscous liquid medium among the friction pairs are enhanced, the thermal deformation of the dual disc of the hydro-viscous speed regulating clutch is reduced, the generation of non-thorough separation between a driving friction part and a driven friction part is prevented, the working performance of the hydro-viscous speed regulating clutch is improved and the service life of the hydro-viscous speed regulating clutch is prolonged.

Owner:JIANGSU UNIV

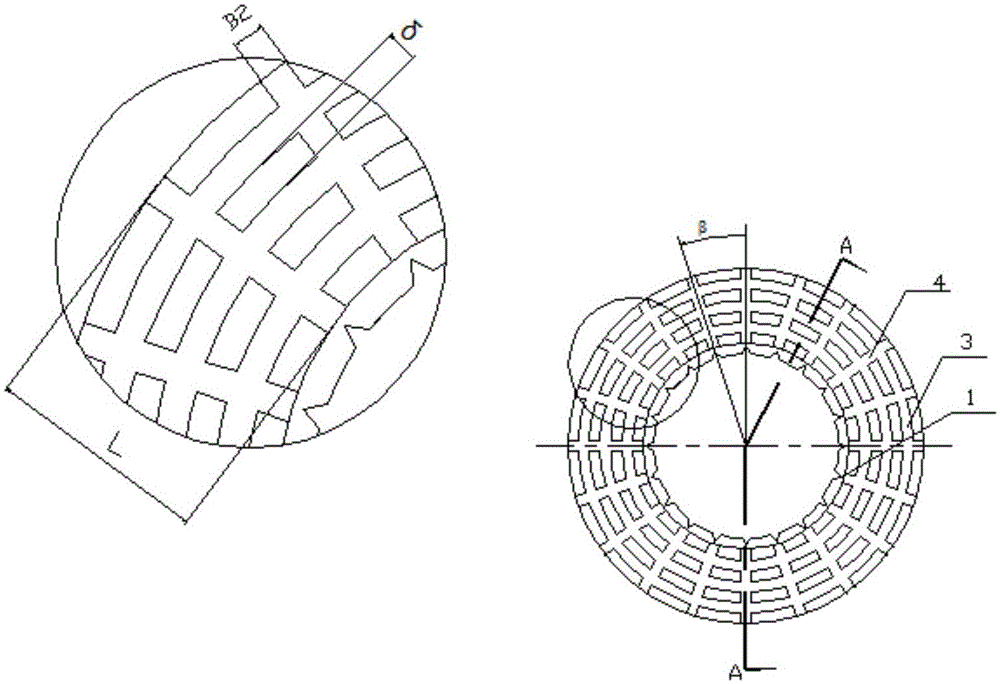

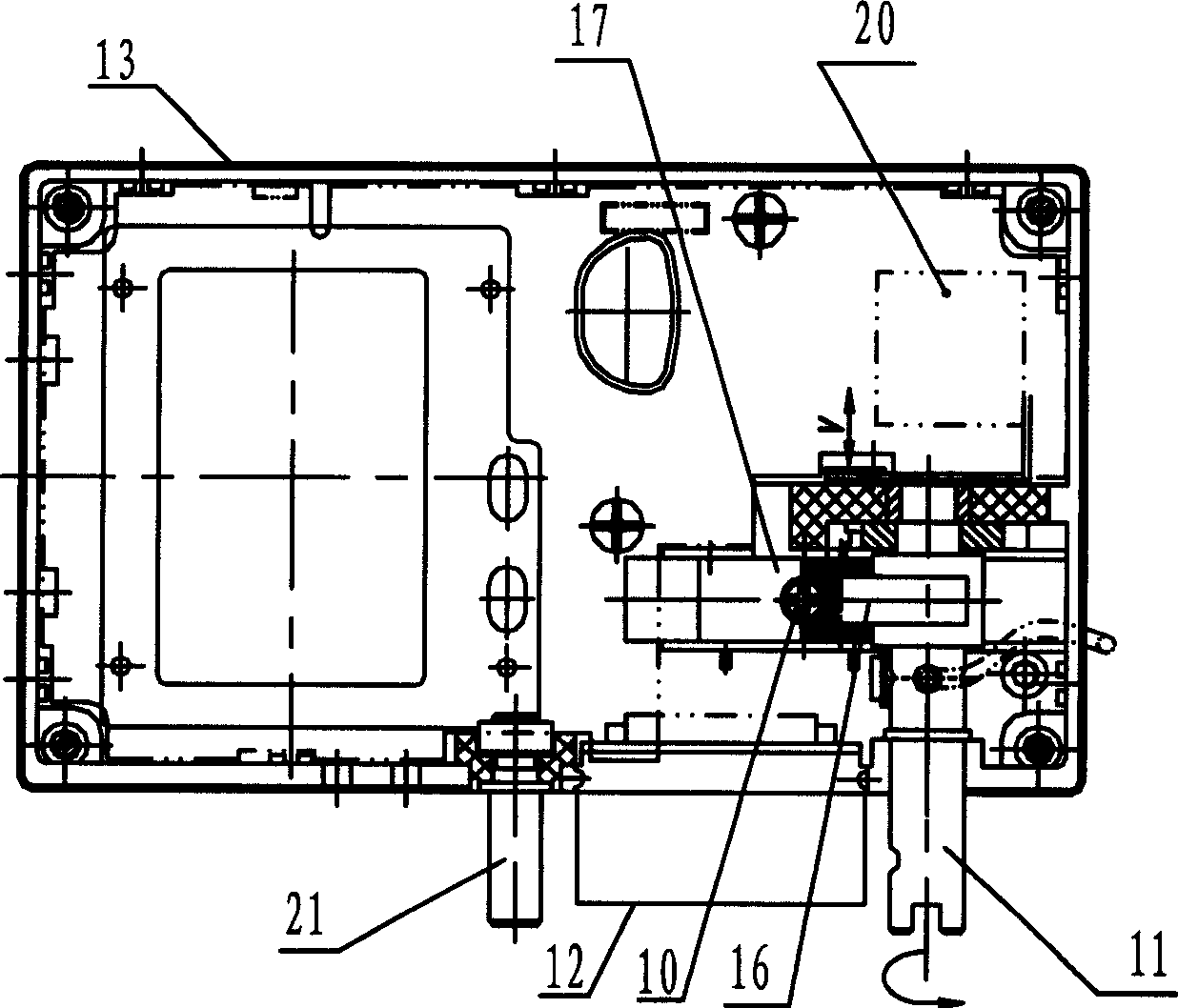

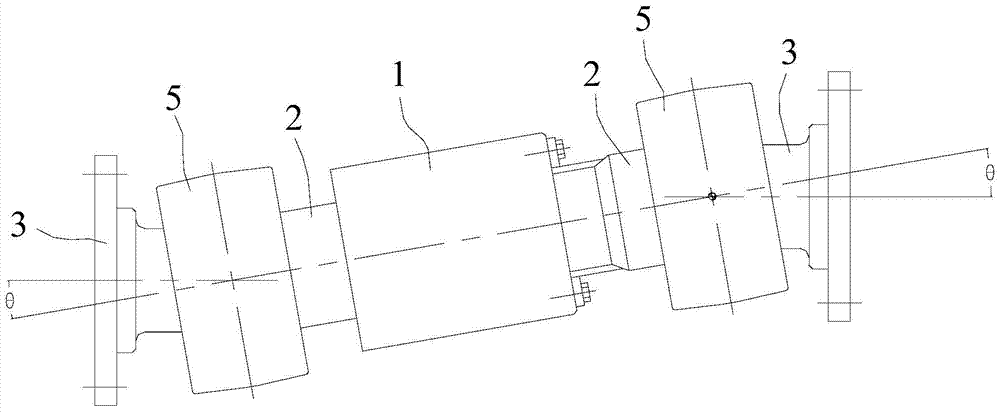

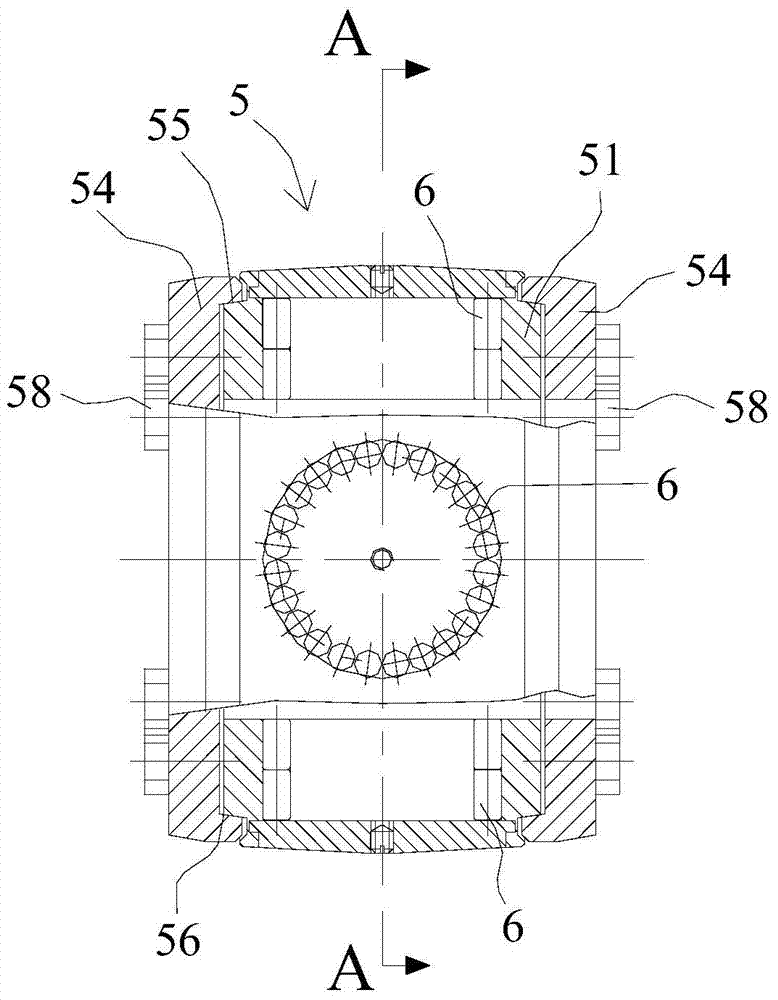

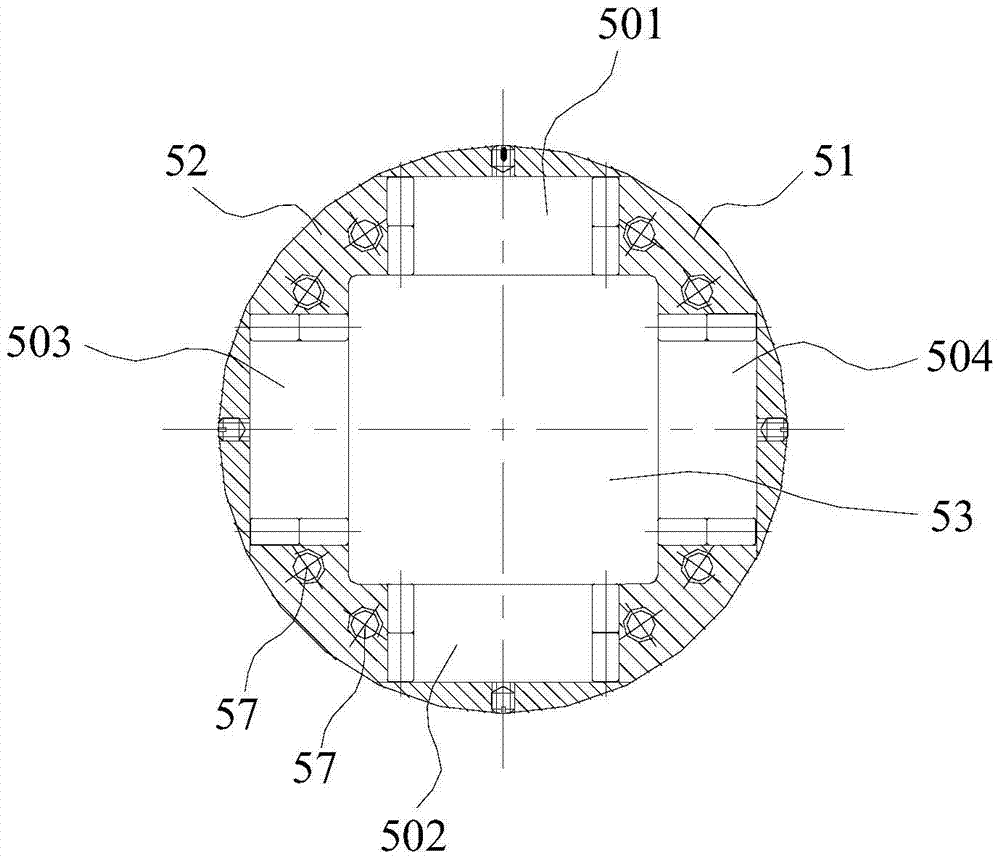

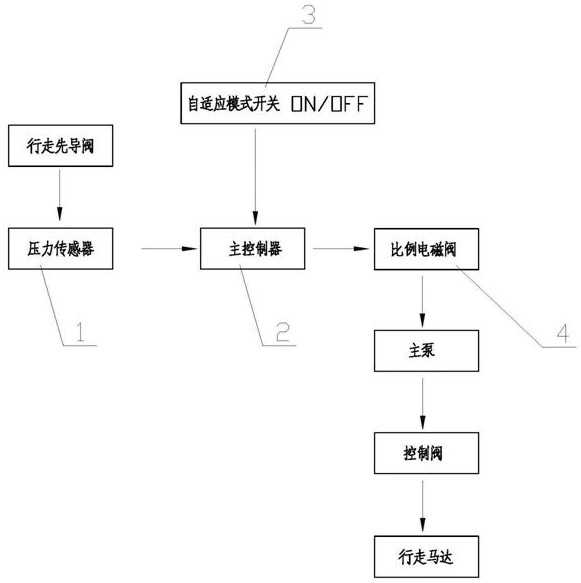

Walking condition adaptive control system and method for excavator, and excavator

ActiveCN109024752AWalk fastIncreased maximum torqueSoil-shifting machines/dredgersMaximum torqueSolenoid valve

The invention discloses a walking condition adaptive control system and method for an excavator. The adaptive control system comprises a pressure sensor arranged on a walking pilot valve, a main controller arranged on a rack, an adaptive mode switch arranged on a trim panel in a cab, and a proportional solenoid valve arranged on a main pump. When the adaptive mode switch is set to ON, the pilot pressure of the walking pilot valve is collected through the pressure sensor, and the pressure signal is transmitted to the main controller; the current pilot pressure and the working mode of the main pump are detected through the main controller; and when the pilot pressure is no less than 8 bar, the corresponding command is output through the main controller according to the current working mode of the main pump. According to the adaptive control system, the walking condition is identified through the system automatically, and the power of the main pump is improved in the light load mode automatically, so that the flow supplied to a walking motor is improved; the walking speed of the excavator is increased, and the walking time is shortened; the working efficiency is improved; and on the other hand, through increase of the flow, the maximum torque of the walking motor is improved.

Owner:XCMG EXCAVATOR MACHINERY

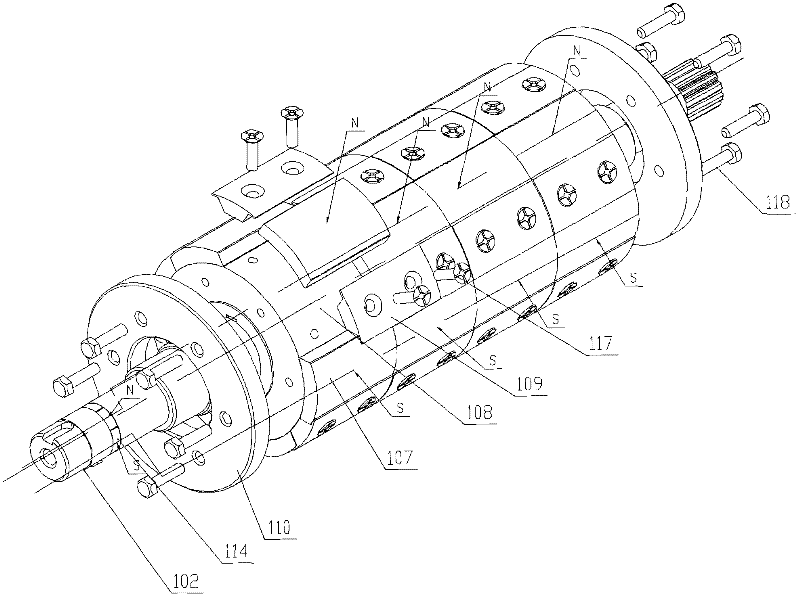

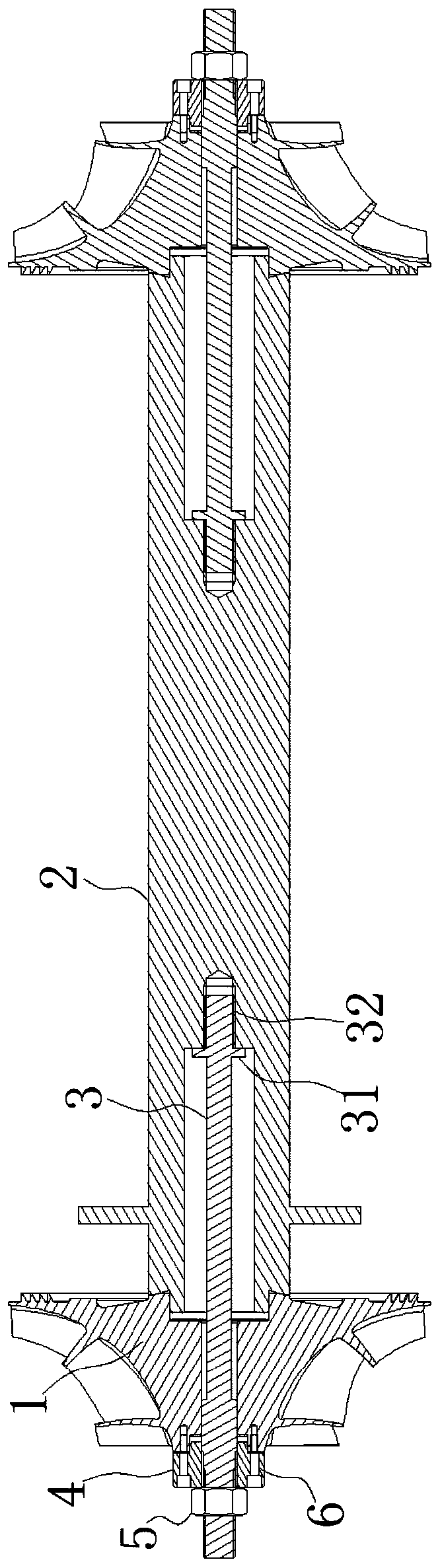

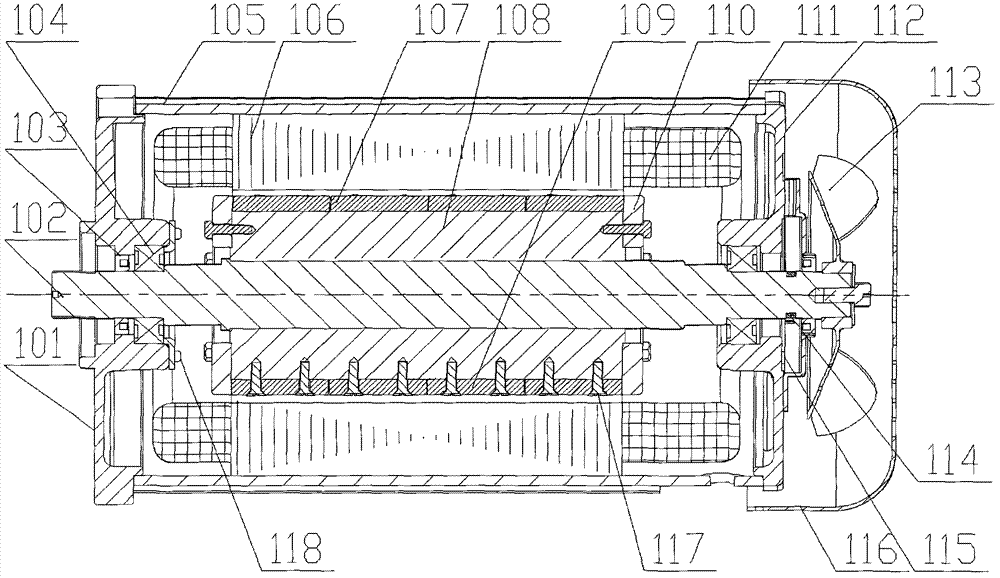

Permanent magnet brushless DC (direct current) motor

ActiveCN102364846ALarge magnet surface areaImprove the magnetic effectMagnetic circuit rotating partsMagnetic circuit stationary partsHall elementMagnetic poles

The invention discloses a permanent magnet brushless DC (direct current) motor which comprises a front end cover, a rear end cover, an enclosure, a stator, a rotor and a Hall element sensor circuit board, wherein the rotor comprises a rotor shaft, a rotor yoke, magnetic steels, magnetic steel baffles and magnetic steel clapboards; the rotor yoke is not provided with a rotor sheet; the magnetic steels are fixed on the outer periphery of the rotor yoke and are shielded by the magnetic steel baffles positioned at both ends of the rotor yoke; and the magnetic clapboards are arranged between the magnetic steels with different magnetic poles. In the invention, the rotor is not provided with the rotor sheet, so that the rotor has a more reasonable structure and the rotor sheet does not need to be formed in the machining process, and thus, the permanent magnet brushless DC motor is convenient to process, is simple to assemble and is firmer to fix the magnetic steels.

Owner:ZHEJIANG ACTIVETECH COMP TECH CO LTD

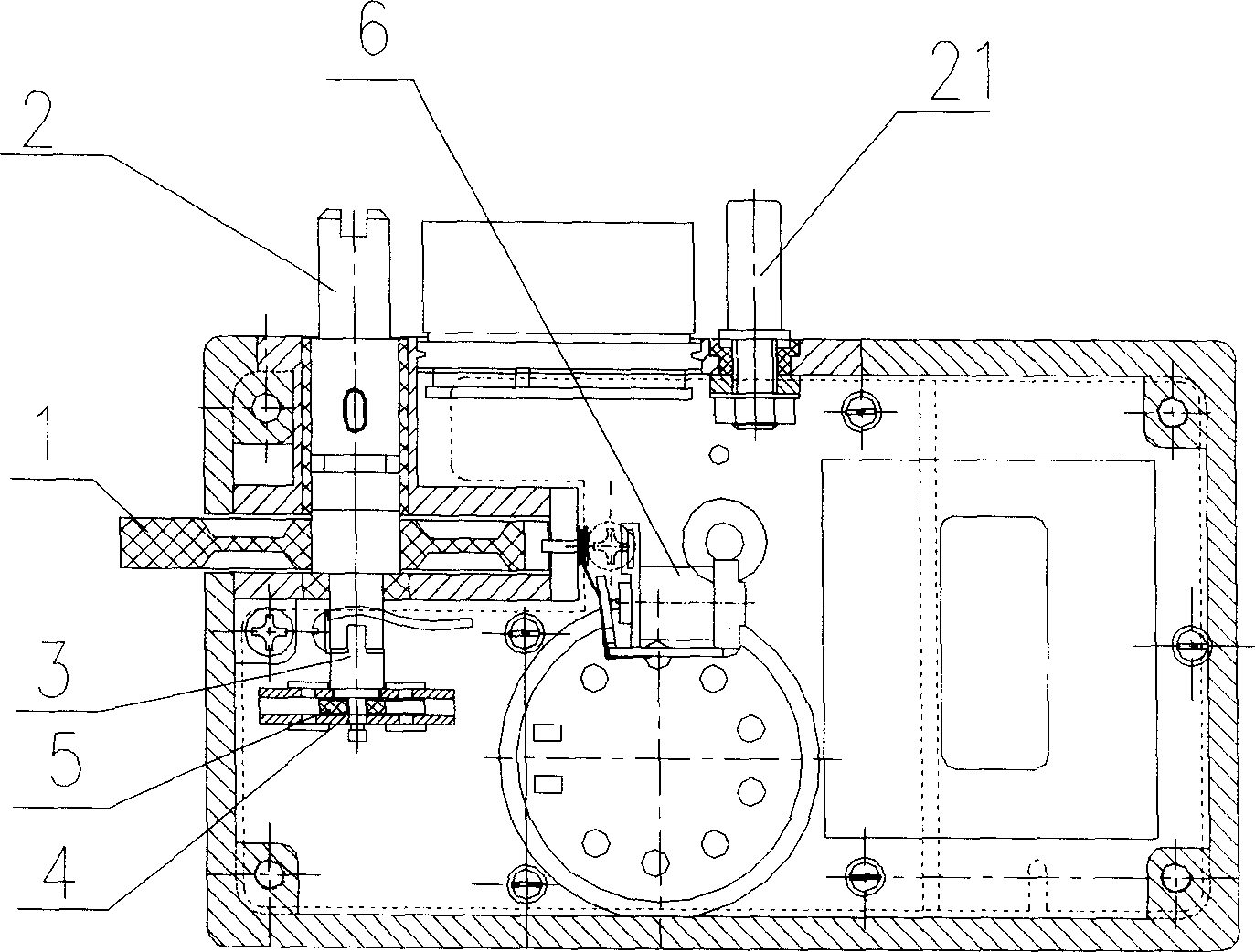

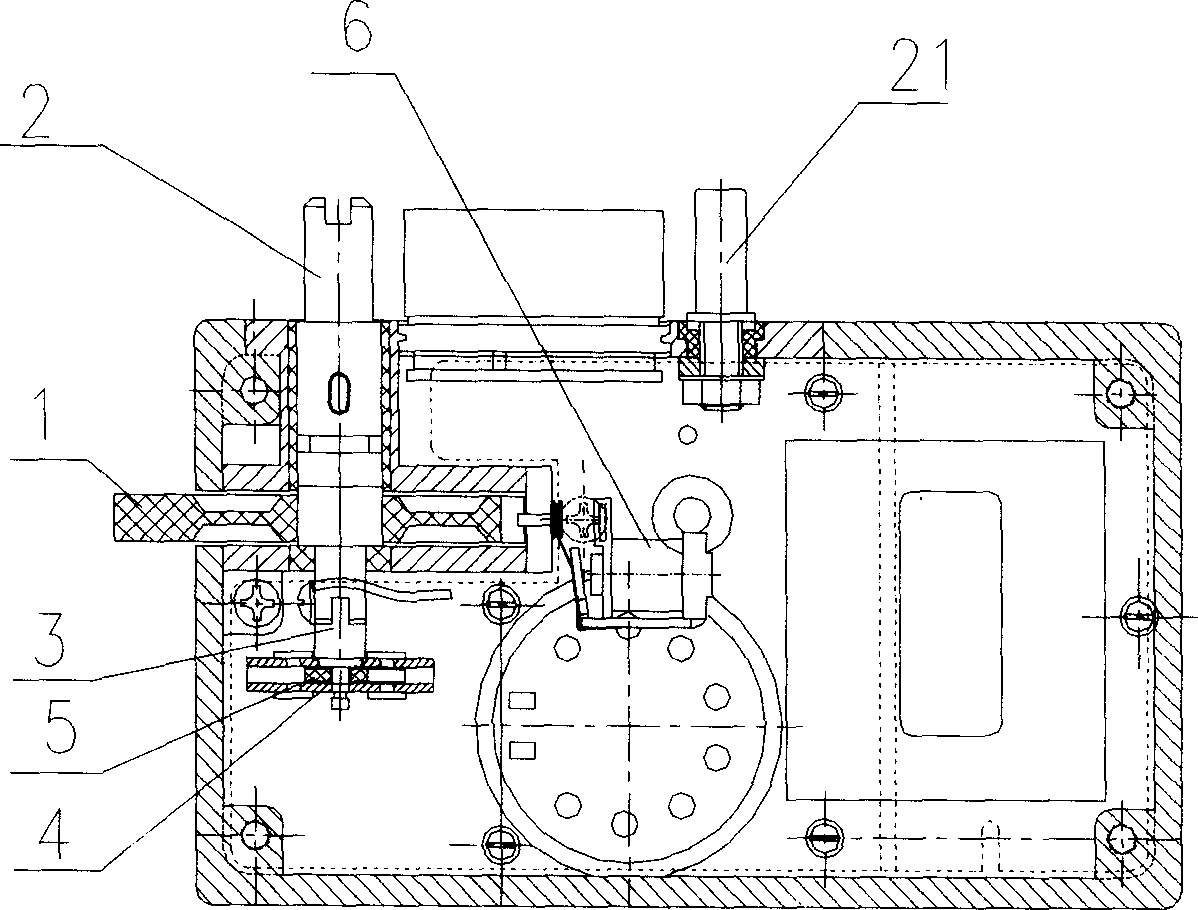

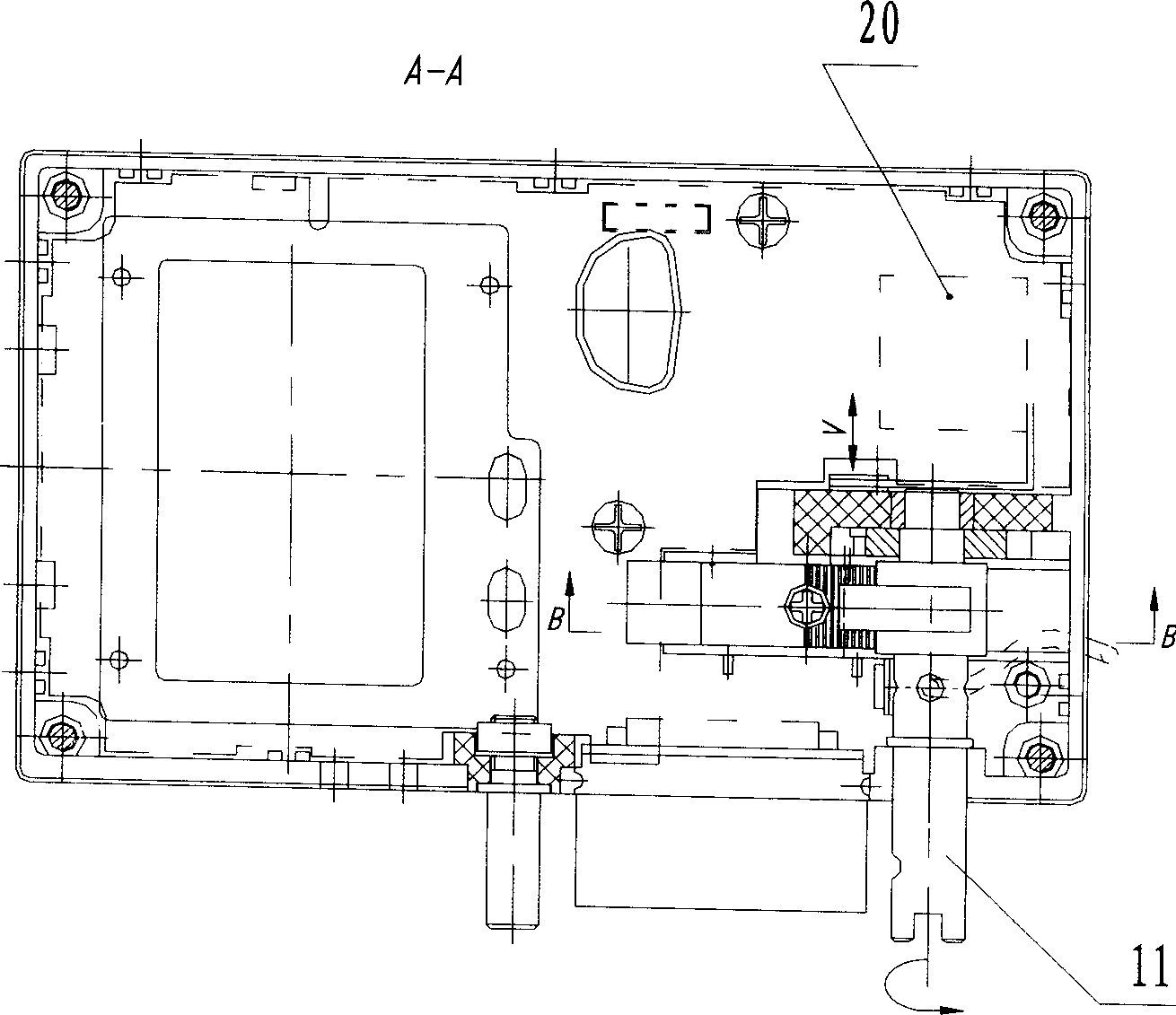

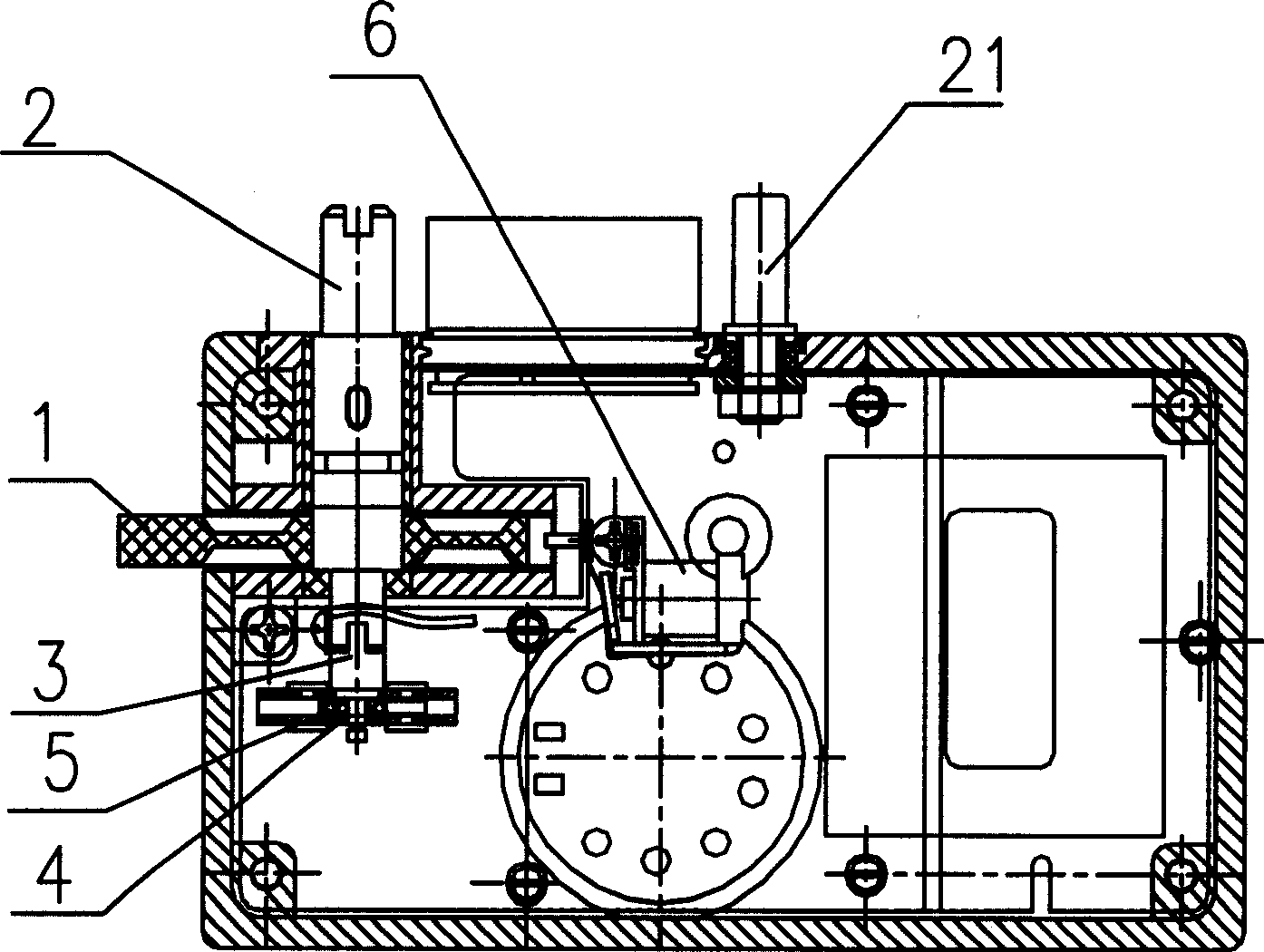

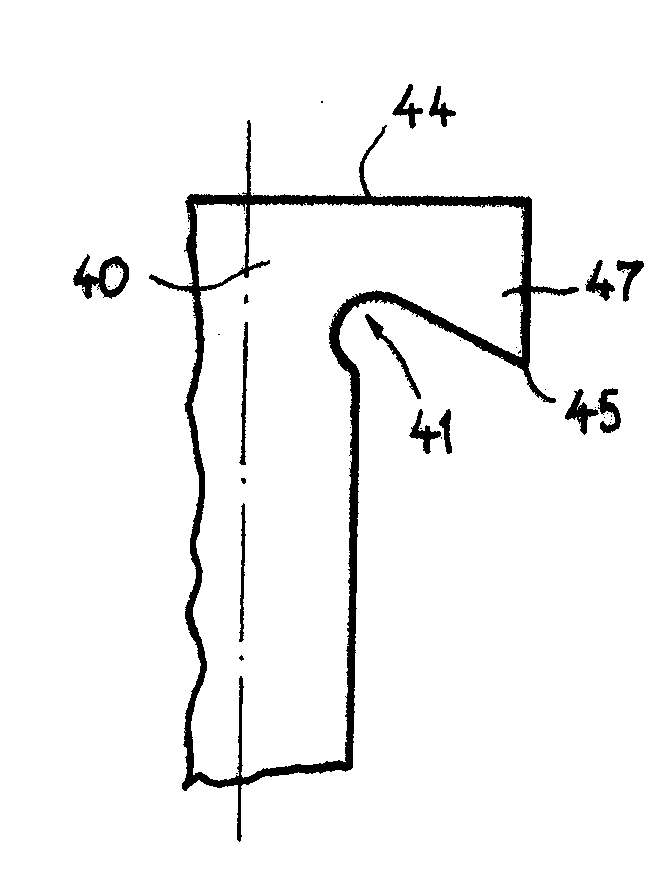

Knob unlocking gear of computer key in error proofing locking gear

ActiveCN1835144AReduce volumeIncreased maximum torqueNon-mechanical controlsElectric switchesMicrocomputerGear wheel

The invention is especially related to guiding against error operation of blocking devices and assemblies for microcomputer in order to prevent error operation to plant and station for power distribution and delivery. The push button type unlock mechanism includes electromagnet, unit for detecting state of mechanism, and moment transmission mechanism of gear wheel. The mechanism includes rack and gear wheel typed electrode axis, which are engaged each other to implement moment transmission. Being located at bottom of the rack, the push button is connected to the bottom rigidly. Being installed inside guide groove of case, the rack can be moved up and down. Force of acting on the push button is transferred to the mechanism directly. Under precondition of not increasing transmission rate, using mode of applying force by thumb and through computer key held by hand increases enforceable maximum moment by human body so as to increase maximum unlocking moment for mechanism greatly.

Owner:CYG CONTRON

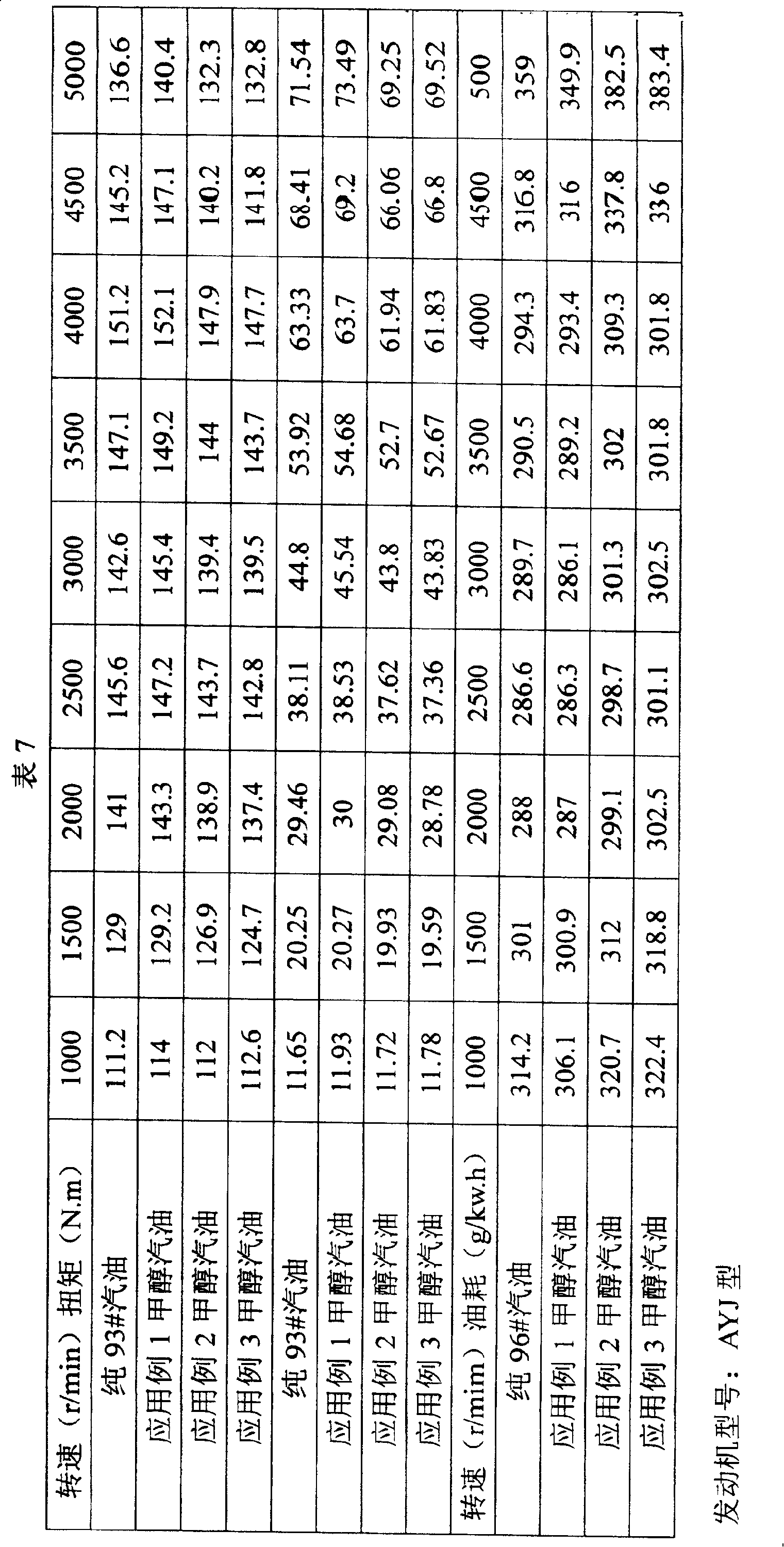

Composite fuel for automobile engine

InactiveCN1919981AWater resistantHas fuel consumptionLiquid carbonaceous fuelsSolventOleic Acid Triglyceride

The invention relates the car engine composite fuel, comprising 30-90% petrol, 10-70% methanol, 0.5 -3% assisting solvent. The assisting solvent comprises 30-60% oleic acid or naphthenic acid or lactic acid, 1-3% orthotoluidine or triethylamine, 806-11% tuwen, 25-63% benzene, and 1% anhydrous sodium sulfate. The product is environmental protection and cleaning. The methanol petrol fuel reduces CO and HC concentrations in vehicle exhaust gas, cleaning air and improving contamination condition. The invention has advantages of simple technology and low cost.

Owner:么居标

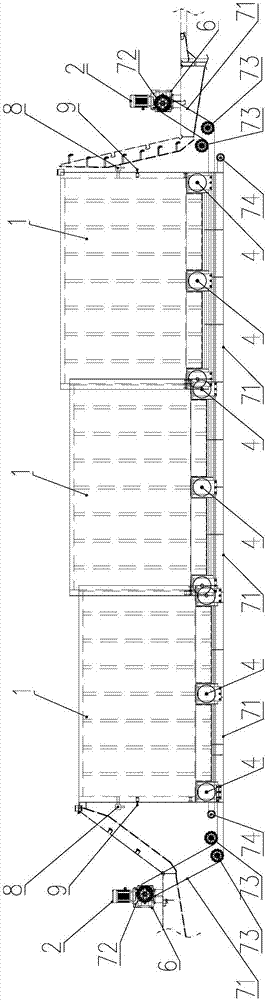

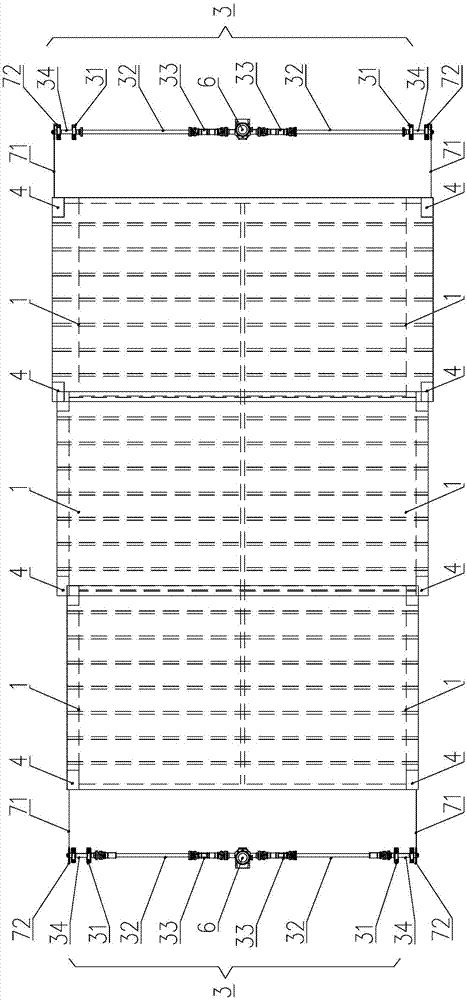

Hatch cover mechanism suitable for full-electric propulsion bulk cargo ship

PendingCN108001618AReduce your weightUniform internal forcePower-operated mechanismVessel hatches/hatchwaysElectricityControl system

The invention provides a hatch cover mechanism suitable for a full-electric propulsion bulk cargo ship and relates to the field of kiloton-grade full-electric propulsion bulk cargo ships. The hatch cover mechanism suitable for the full-electric propulsion bulk cargo ship is located on a main deck, comprises a hatch cover and further comprises motors located at the head end and the tail end of thehatch cover and providing operation power for the hatch cover mechanism, traction devices located on the left side and the right side of the hatch cover and driving the hatch cover to move towards thehead or the tail, at least four sets of idler wheel components bearing the bottom of the hatch cover, a track component located below the idler wheel components and making the hatch cover to be borneby the idler wheel components and move towards the head or the tail along the track component under the effect of the traction devices, and a control system electrically connected with the traction devices and used for controlling the traction devices to be started or stopped. The electric power effect is adopted in the whole motion process, fuel and the like are not used as power, pollution of waste emission does not exist, the hatch cover mechanism is a clean measure to achieve hatch cover motion, and the traction devices are remotely controlled through the control system to be started or not.

Owner:ZHEJIANG MODERN SHIP DESIGN RES +1

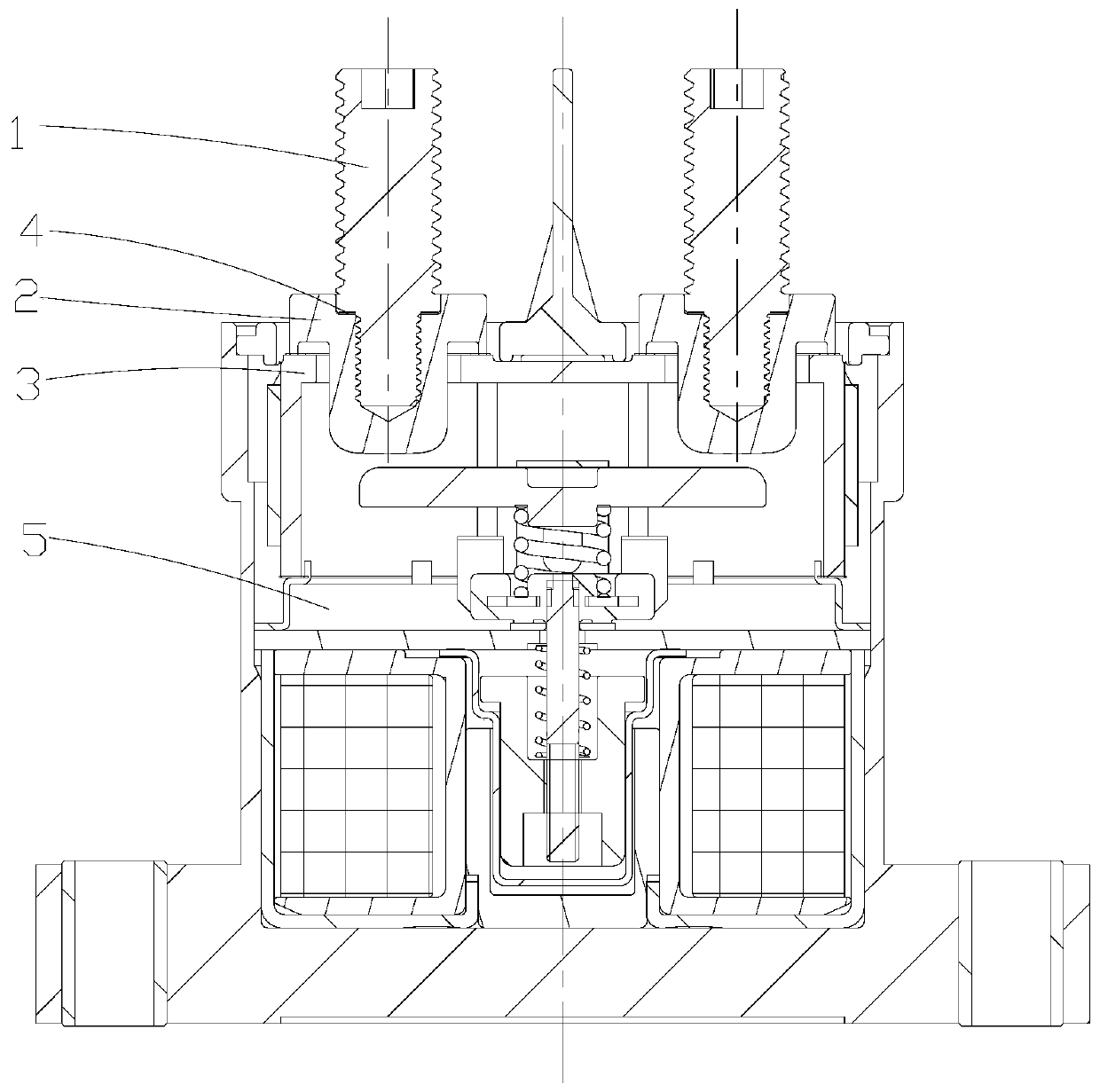

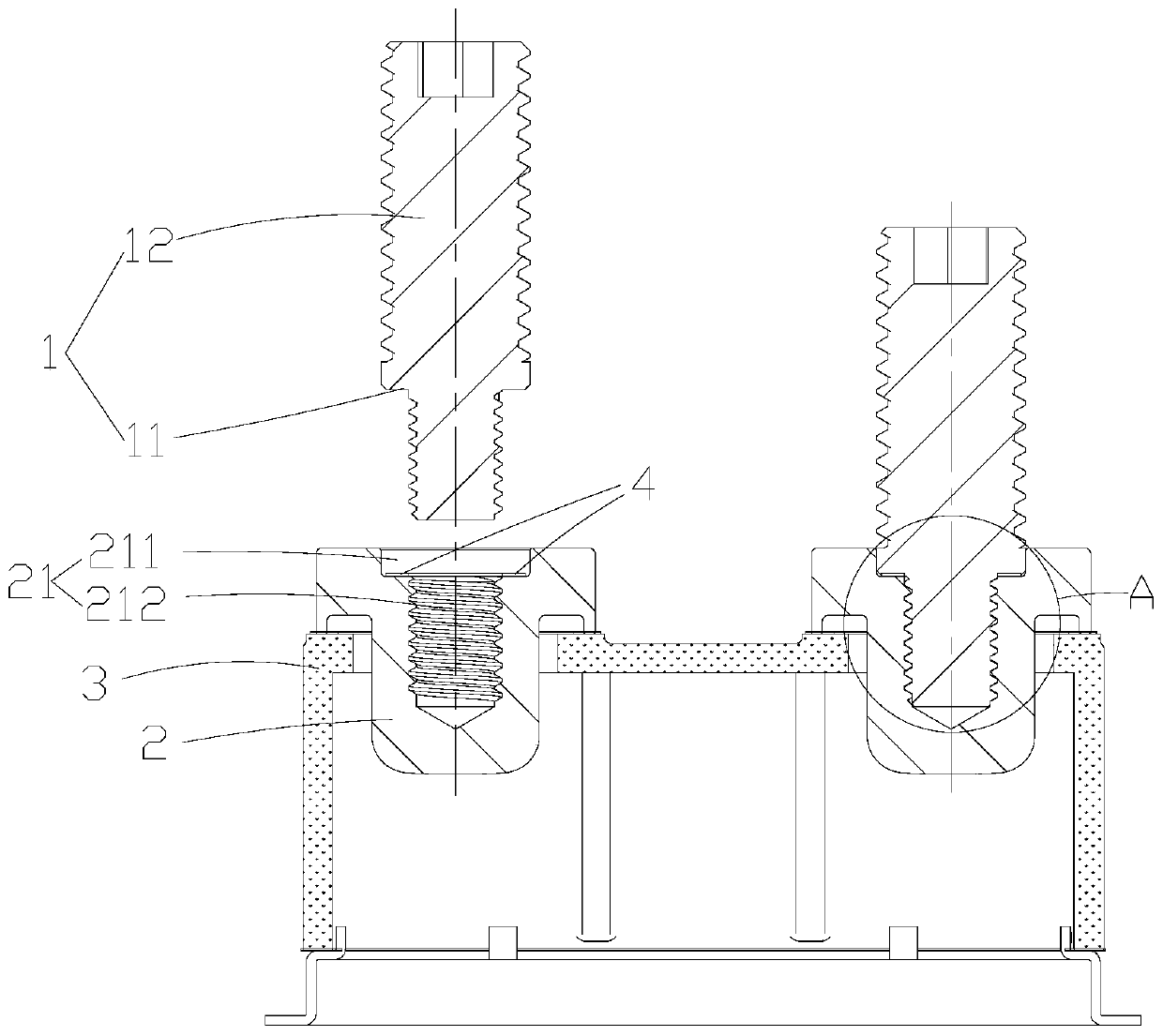

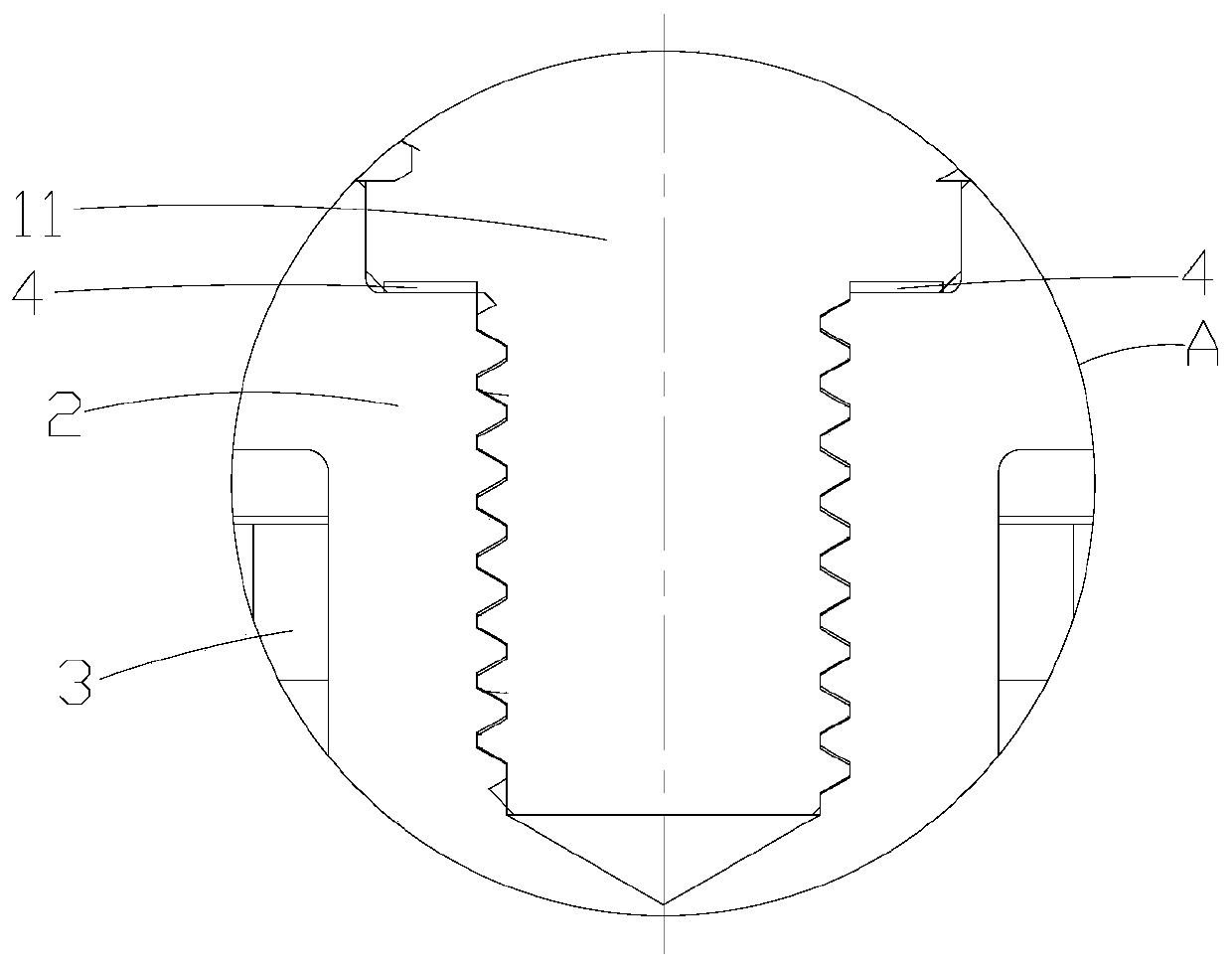

Load terminal of high-voltage direct-current relay

PendingCN109859990AImprove connection stabilityImprove use reliabilityElectromagnetic relay detailsSolderingEngineering

The present invention discloses a load terminal of a high-voltage direct-current relay. The load terminal comprises a connection terminal and a lead-out terminal arranged on a relay ceramic cover, thehead of the lead-out terminal is provided with a holding hole, the lower end of the connection terminal is adaptively inserted into the holding hole and is in screw-thread fit connection with the holding hole, a pressing block is in brazed connection at the mouth of the holding hole of the lead-out terminal through soldering lug, the connection terminal is provided with a spacing portion matchedwith the pressing block, the matching of the pressing block and the spacing portion can press the lower end of the connection terminal into the holding hole to prevent the connection terminal from dropping off. The maximum torque value of the connection terminal is large to allow connection terminals with various thread specifications to meet the torque requirements when the connection terminals are used, the lower end of the connection terminal is pressed into the holding hole to prevent the connection terminal from dropping off through matching of the pressing block and the spacing portion,the connection terminal can be vertically connected with the lead-out terminal through screw-thread fit of a lower thread portion and a small hole, and therefore, the load terminal of the high-voltagedirect-current relay has good use reliability.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

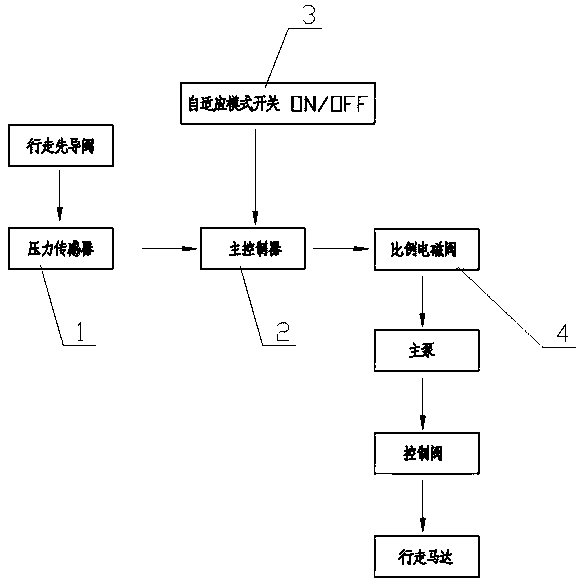

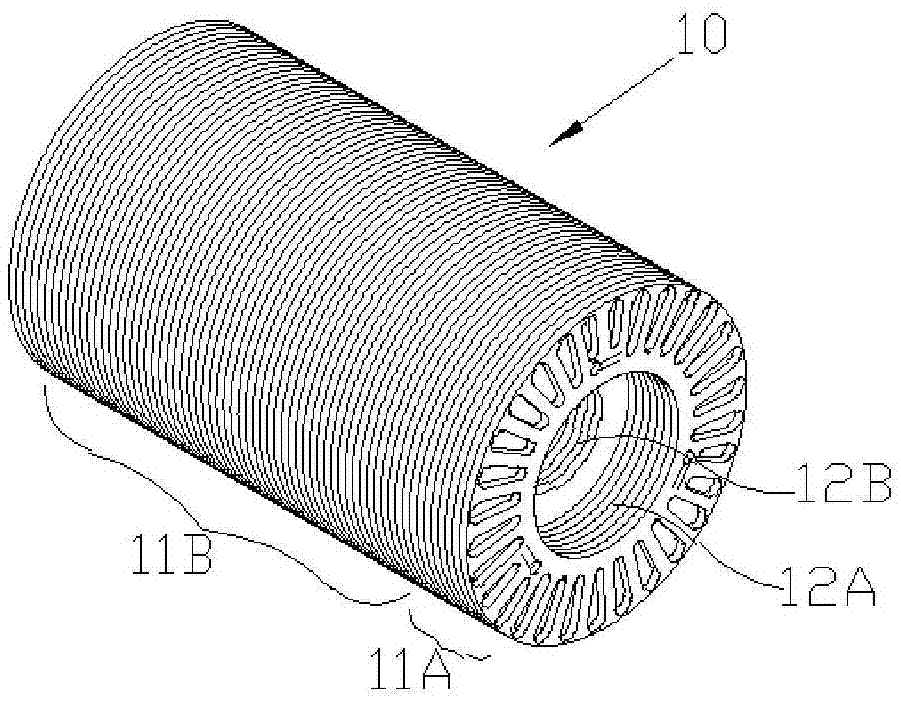

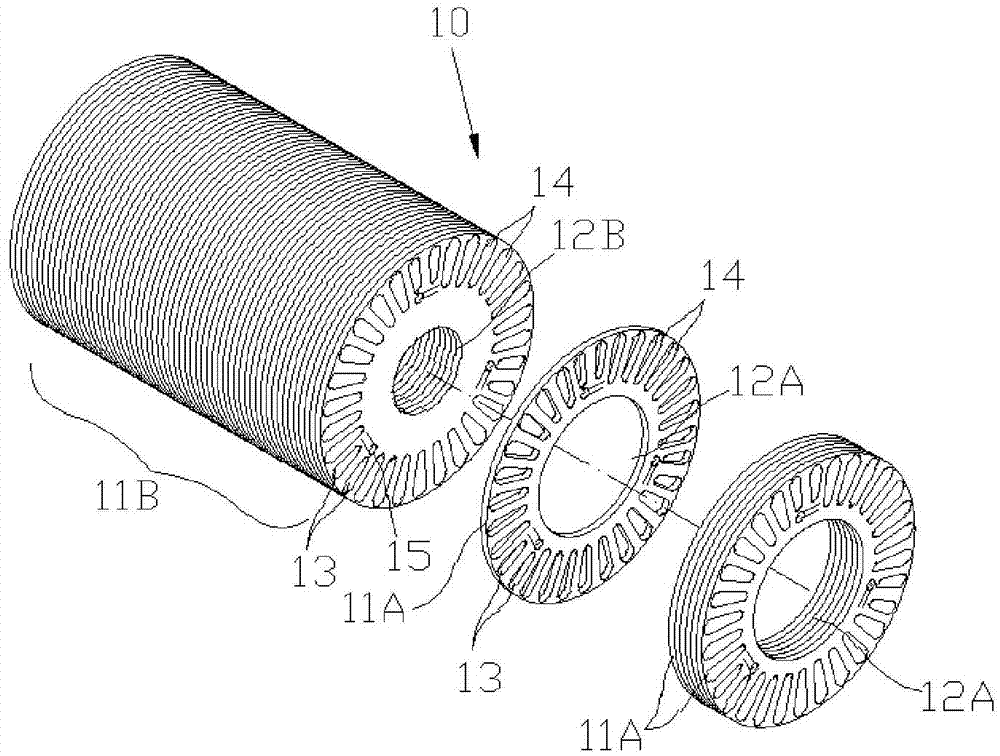

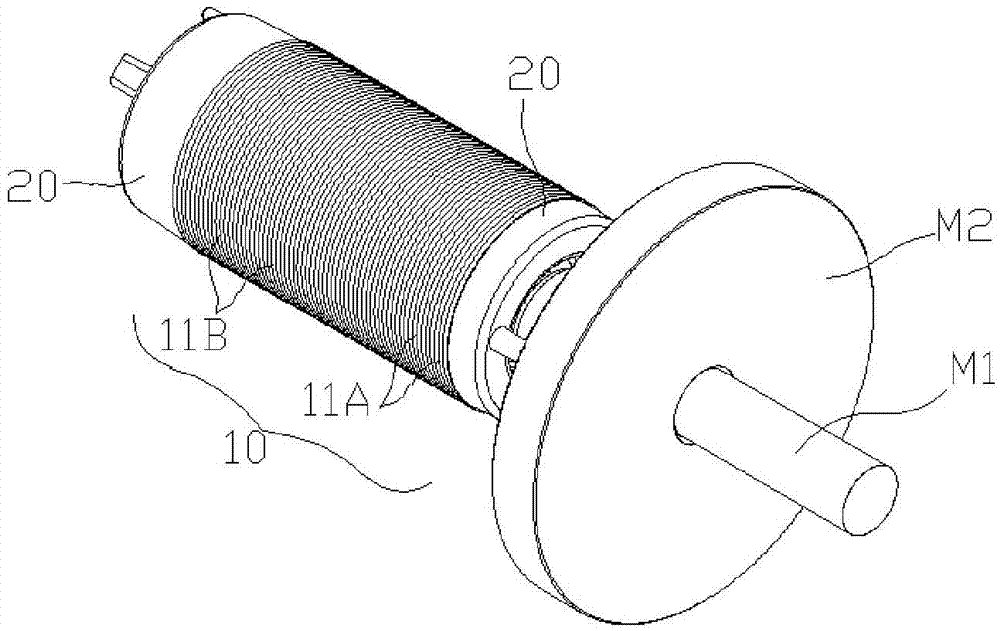

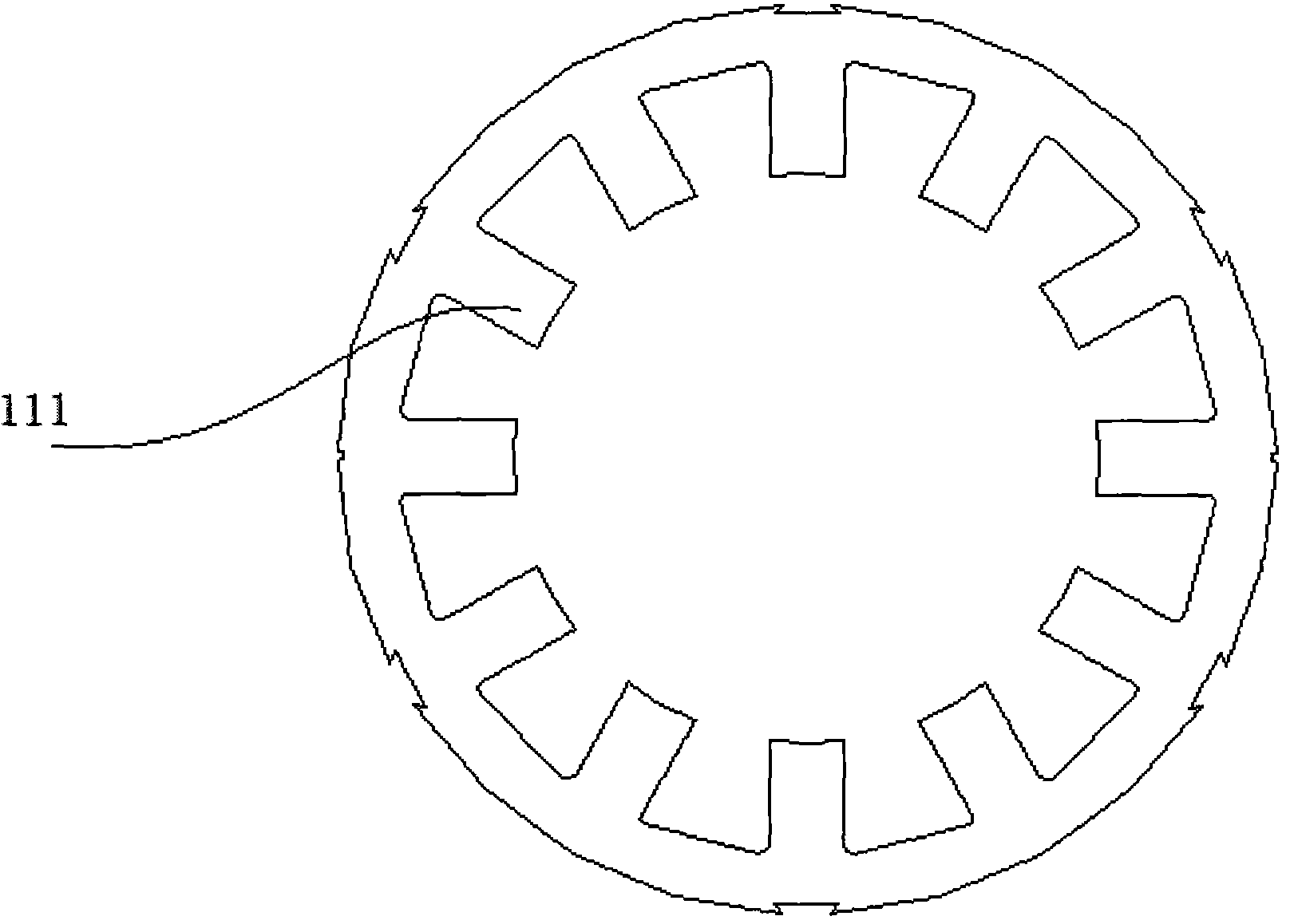

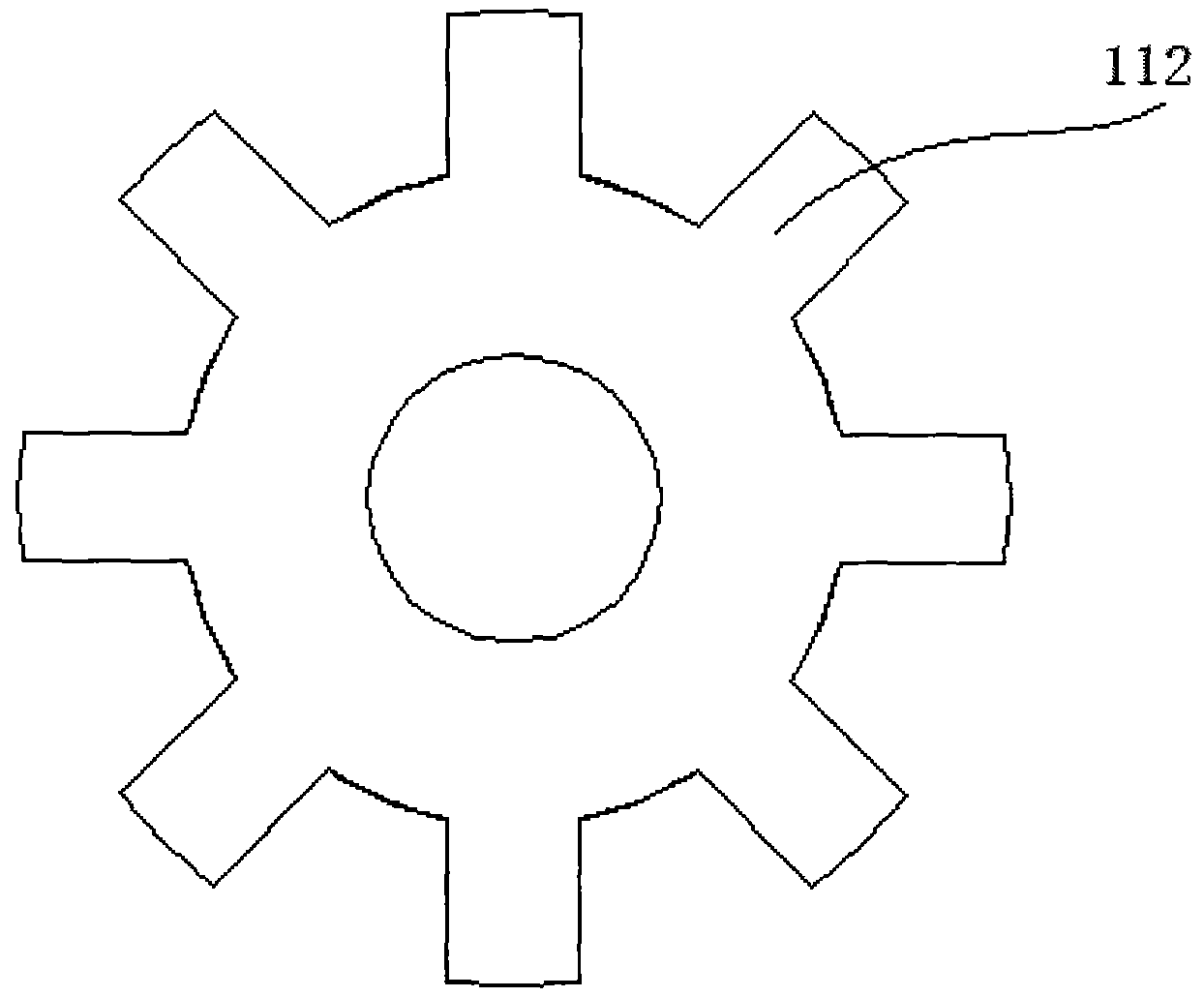

Self-riveting motor rotor iron core

InactiveCN107196432AIncreased maximum torqueImprove operational efficiencyMagnetic circuit rotating partsMaximum torqueSilicon

The invention provides a self-riveting motor rotor iron core which is provided with an iron core body formed by plural silicon steel plates through laminated combination. Each silicon steel plate is provided with a shaft hole at the center. The periphery of the shaft hole is provided with plural slot holes which are configured in a surrounding way in the preset space. Plural self-riveting points are evenly distributed in the area between the shaft hole and the slot holes. Each silicon steel plate is provided with at least two types of slot holes of different lengths, and the length of the slot hole corresponding to the self-riveting points of each silicon steel plate is relatively less than the length of the slot hole which is not corresponding to the self-riveting points. Therefore, the limitation of the self-riveting points can be avoided, and the maximum torque of the motor can be increased by changing the shape of the rotor slot holes under the condition that the winding parameters cannot be broken through.

Owner:RECHI PRECISION

Knob unlocking gear of computer key in error proofing locking gear

ActiveCN100474473CReduce volumeIncreased maximum torqueNon-mechanical controlsElectric switchesMicrocomputerGear wheel

The invention is especially related to guiding against error operation of blocking devices and assemblies for microcomputer in order to prevent error operation to plant and station for power distribution and delivery. The push button type unlock mechanism includes electromagnet, unit for detecting state of mechanism, and moment transmission mechanism of gear wheel. The mechanism includes rack and gear wheel typed electrode axis, which are engaged each other to implement moment transmission. Being located at bottom of the rack, the push button is connected to the bottom rigidly. Being installed inside guide groove of case, the rack can be moved up and down. Force of acting on the push button is transferred to the mechanism directly. Under precondition of not increasing transmission rate, using mode of applying force by thumb and through computer key held by hand increases enforceable maximum moment by human body so as to increase maximum unlocking moment for mechanism greatly.

Owner:CYG CONTRON

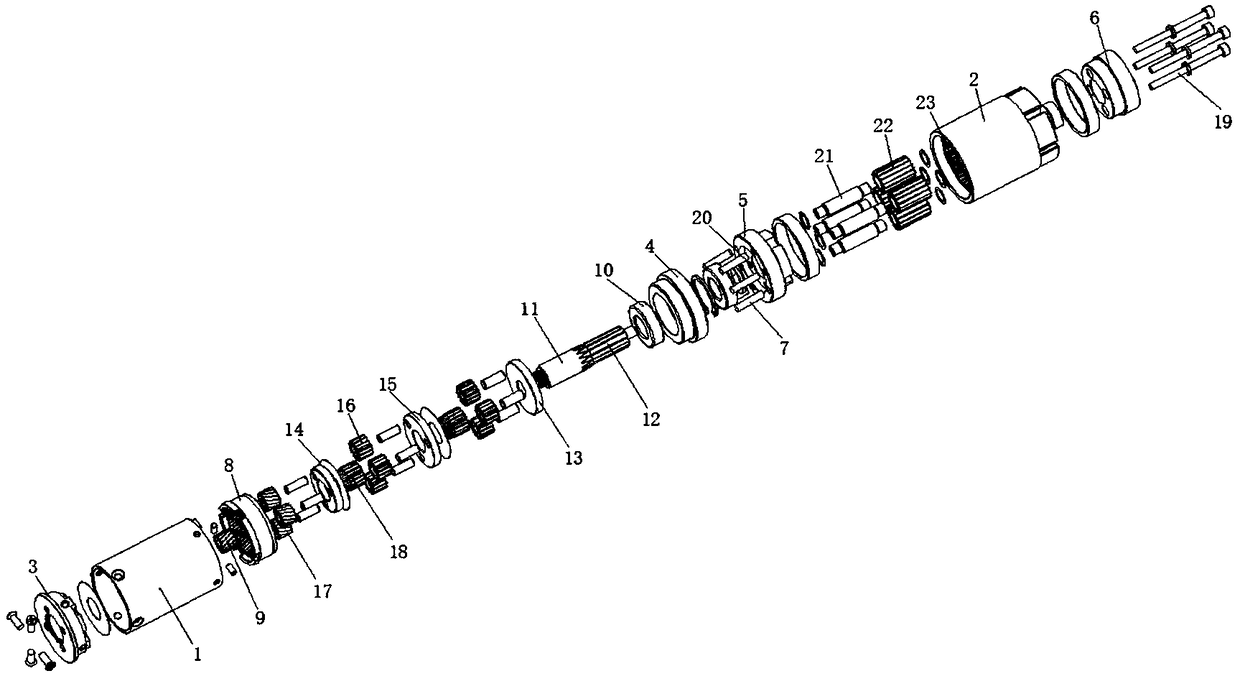

A+B gearbox integrating structure

InactiveCN109340319AIncreased meshing contact strengthLarge load transmission areaToothed gearingsGearing detailsRolling-element bearingHigh torque

The invention discloses an A+B gearbox integrating structure. The A+B gearbox integrating structure comprises an A gearbox body and a B gearbox body, wherein an A box bottom plate is mounted at one end of the A gearbox body, and an A box cover plate is mounted at the other end of the A gearbox body; a B box bottom plate is mounted at one end of the B gearbox body, and a B box cover plate is mounted at the other end of the B gearbox body; a plurality of positioning pins are mounted between the A box cover plate and the B box bottom plate; a rolling bearing which sleeves an output shaft is positioned at one end of the A box cover plate and is rotatably connected into the A gearbox body; a first tooth groove is arranged in one end of the output shaft and is formed in the B gearbox body; a supporting sleeve sleeves an inner hexagonal screw, and a long planetary gear sleeves the supporting sleeve; a second tooth groove is formed in the inner wall of the B gearbox body; and the first tooth groove and the second tooth groove are correspondingly engaged with the long planetary gear. The A+B gearbox integrating structure is high in structure strength, capable of bearing high torque, stableto transmit, and small in noise while running in high-speed and heavy load conditions.

Owner:DONGGUAN SILENT INDAL

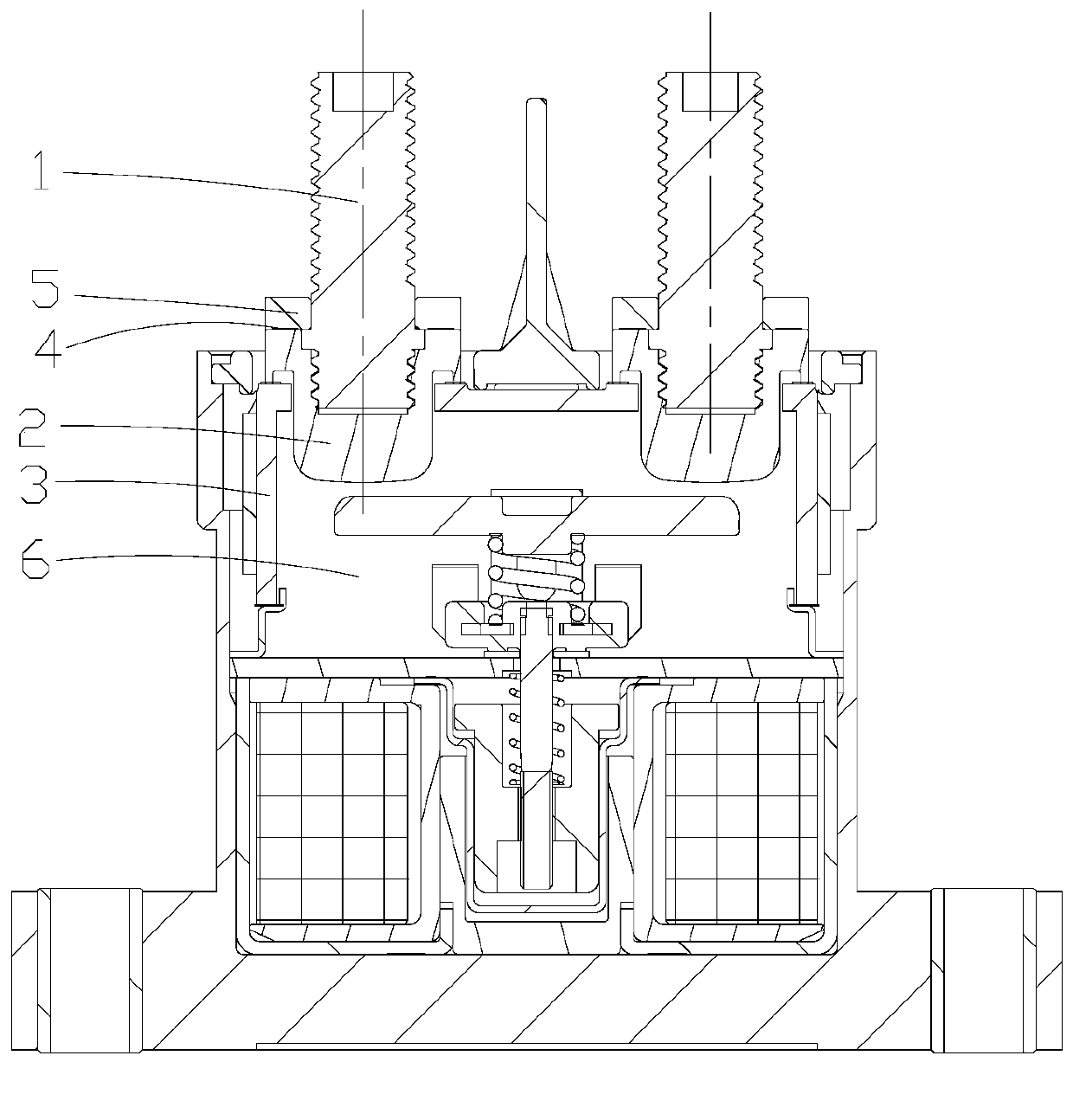

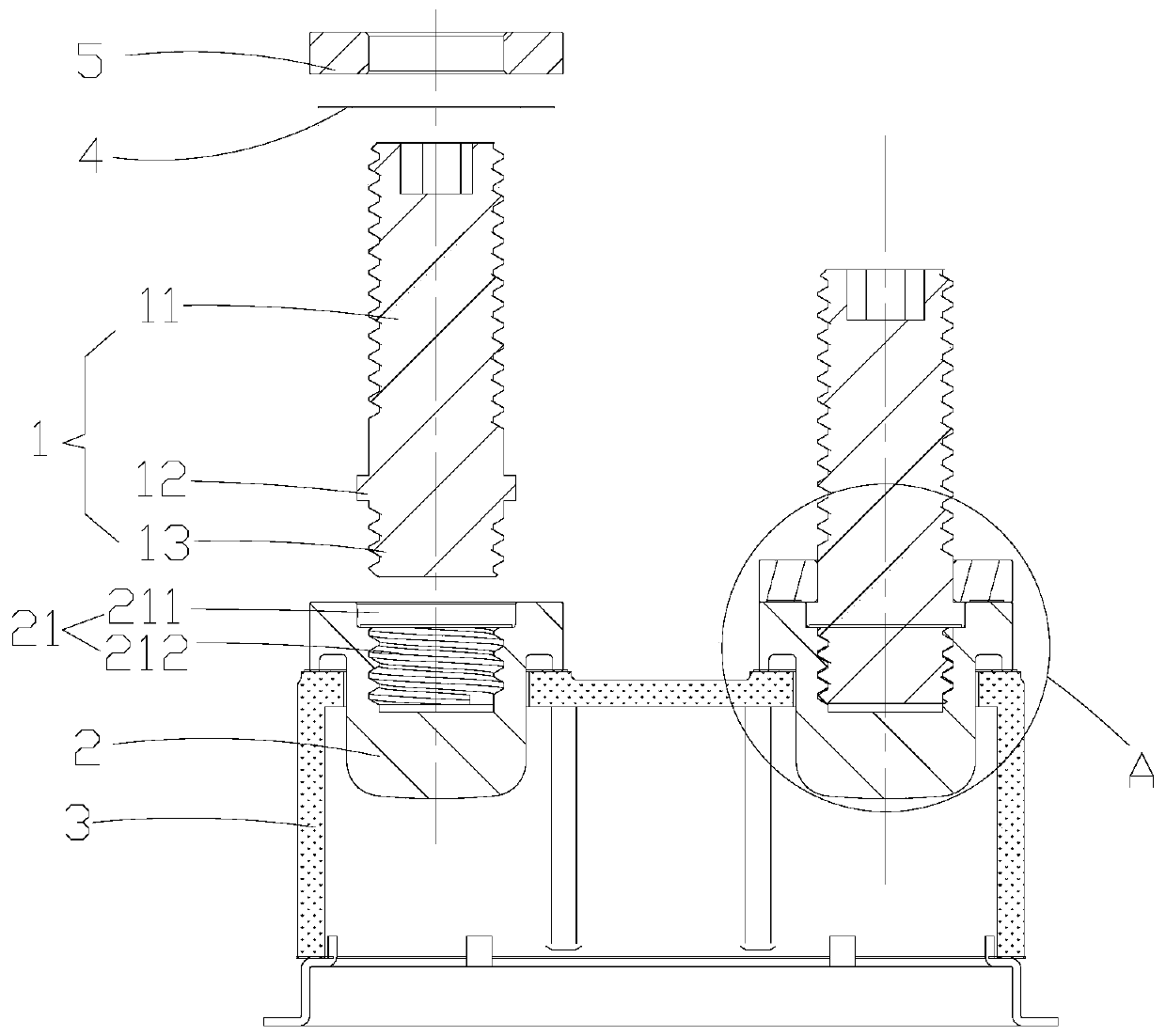

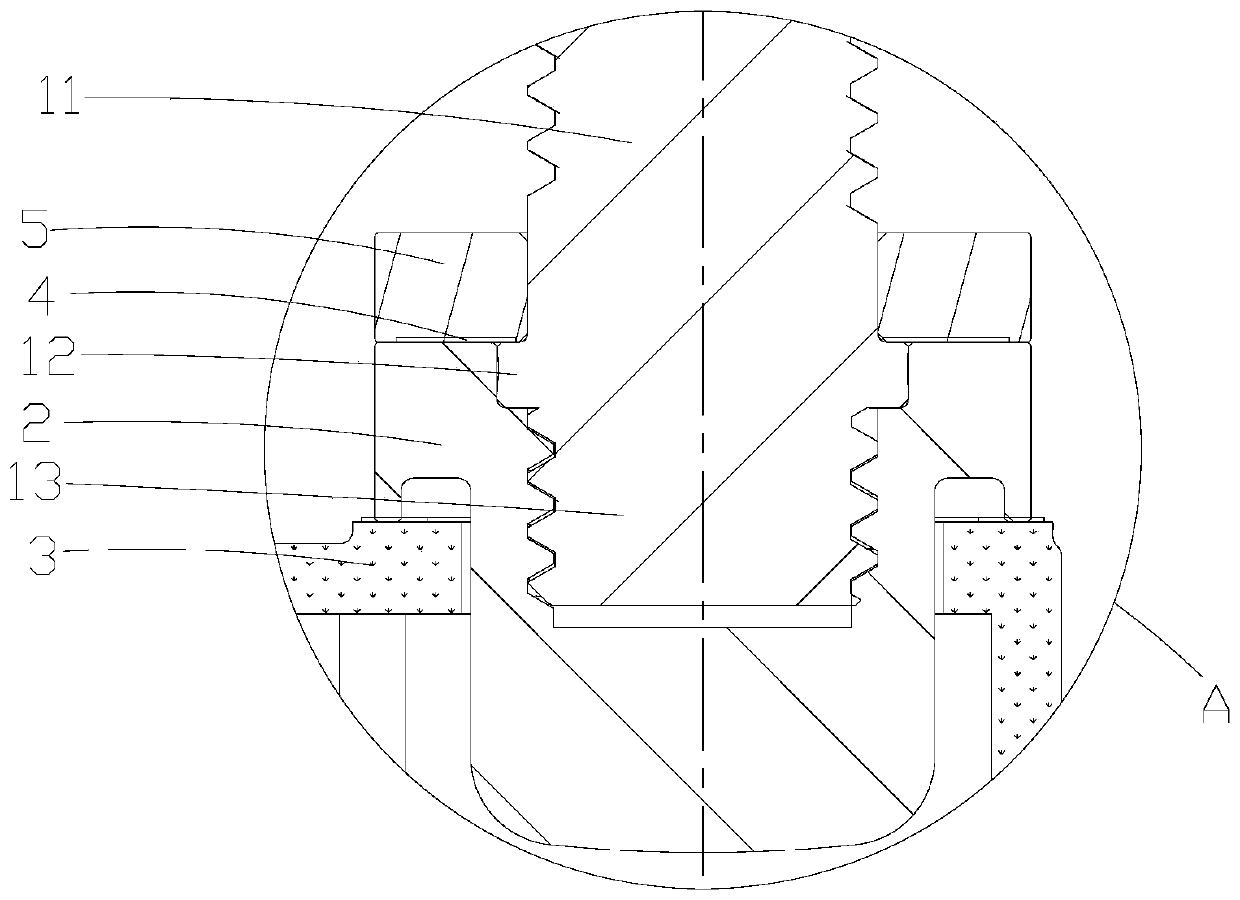

Load terminal of high-voltage direct current (DC) relay

PendingCN109786178AImprove use reliabilityGuaranteed verticalityElectromagnetic relay detailsEngineeringHigh pressure

The invention discloses a load terminal of a high-voltage direct current (DC) relay. The relay comprises connecting ends, and leading-out ends arranged on a ceramic relay cover, wherein a step hole isformed in the head of each leading-out end; a step part is formed at the lower part of each connecting end, and can be adaptively inserted into the corresponding step hole; the step holes are connected with the corresponding step parts through thread fit; a brazing layer, through which each leading-out end can be connected with the corresponding connecting end, is arranged between matched step surfaces of the corresponding step hole and the corresponding step part; and double-connection structures for preventing the connecting ends from loosening and dropping are formed through the thread fitconnection between the step holes and the step parts and the brazed connection between the matched step surfaces of the step holes and the step parts. The load terminal disclosed by the invention hasthe advantages that the maximum torque bearable by the connecting ends is larger; and the double-connection structures for preventing the connecting ends from loosening and dropping are formed through the thread fit connection between the step holes and the step parts and the brazed connection between the matched step surfaces of the step holes and the step parts, so that the connecting ends canbe prevented from dropping when the brazing layers fail, and high use reliability can be further achieved.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

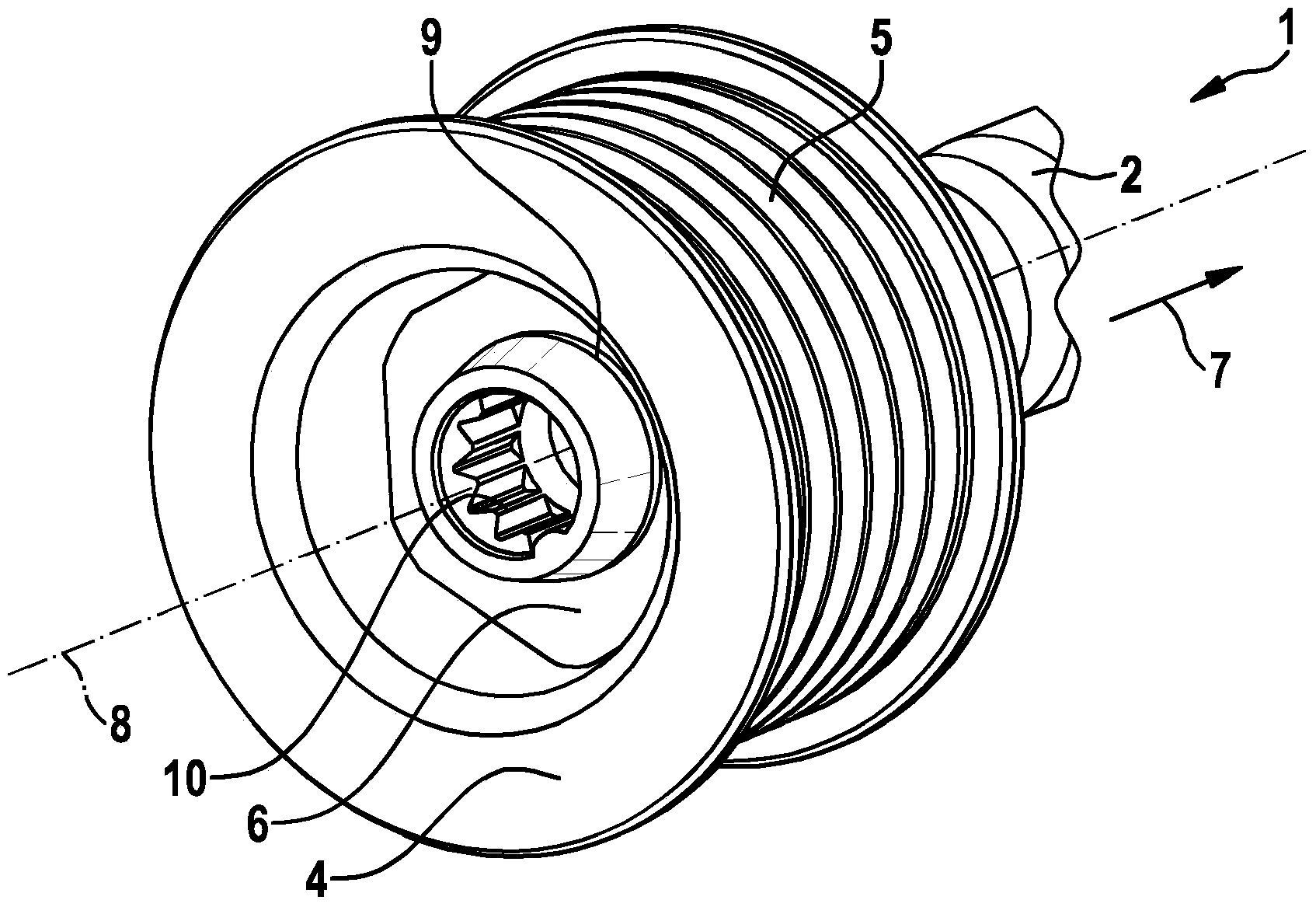

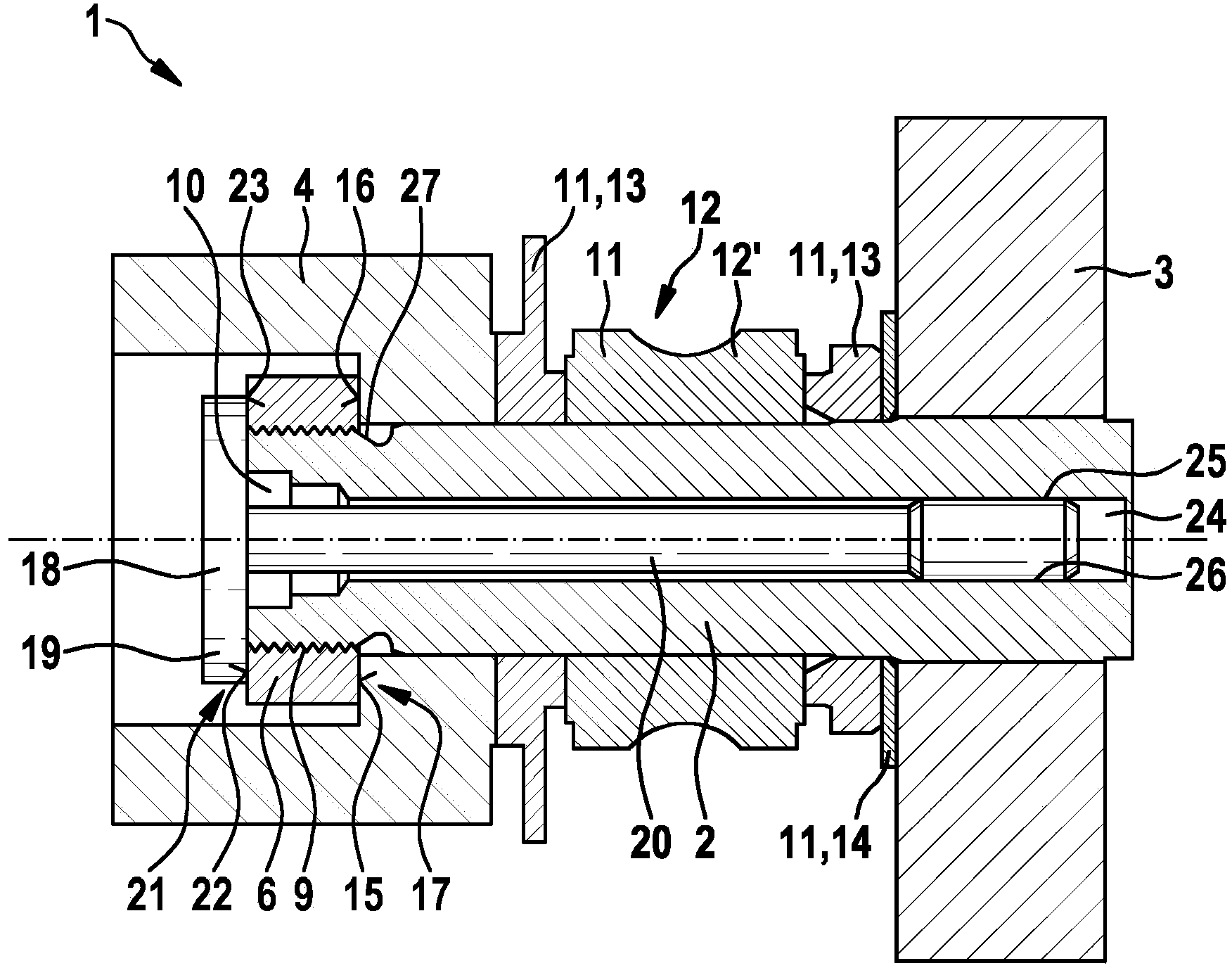

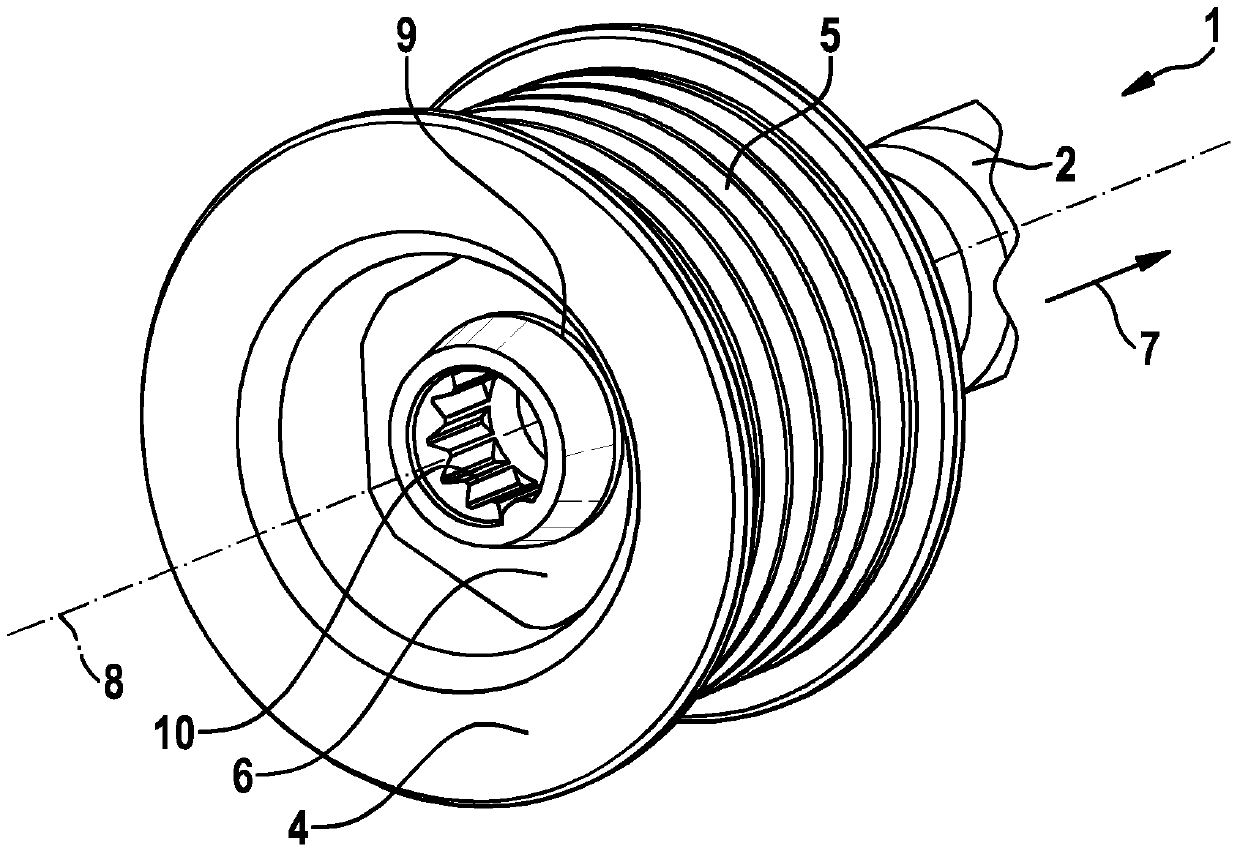

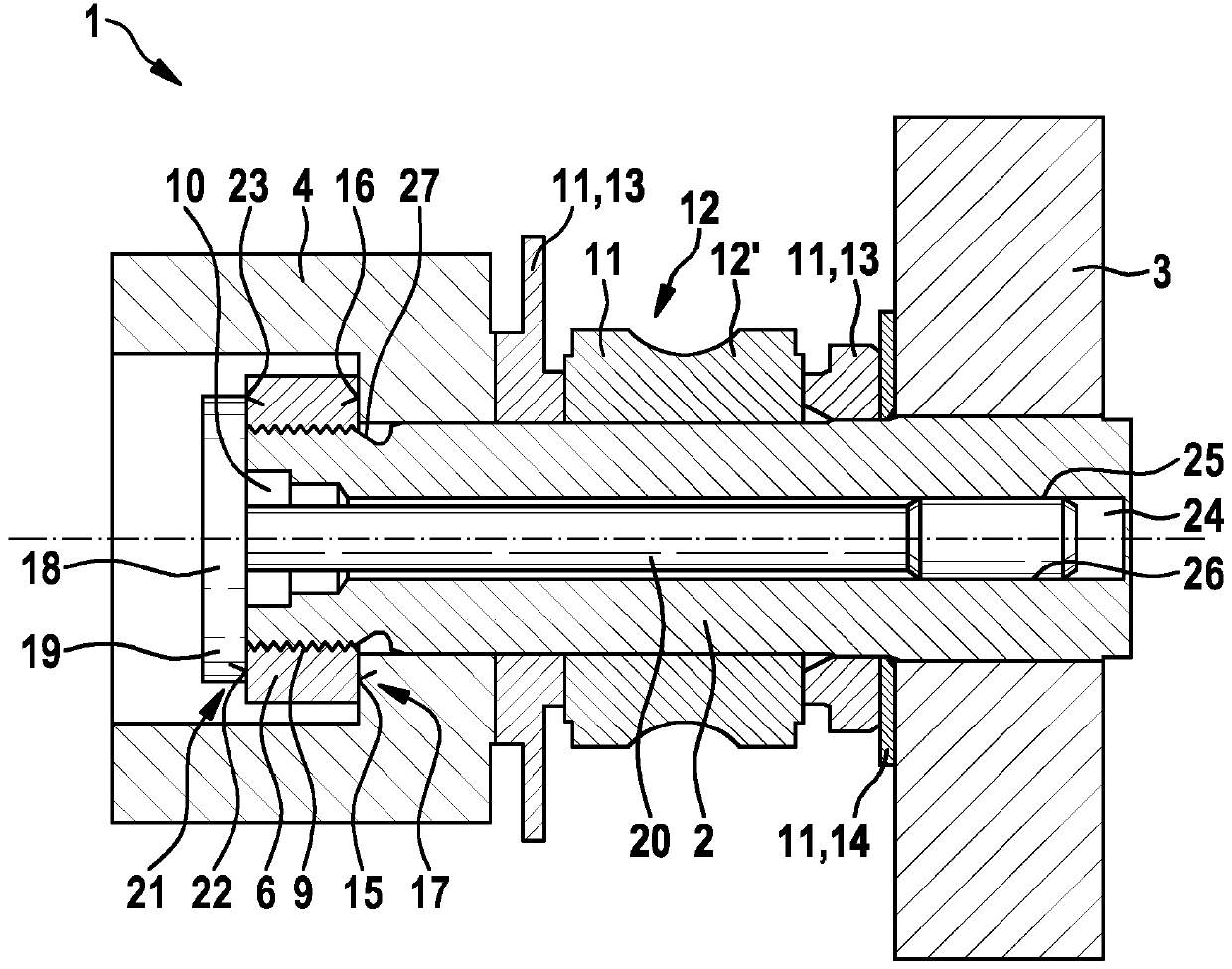

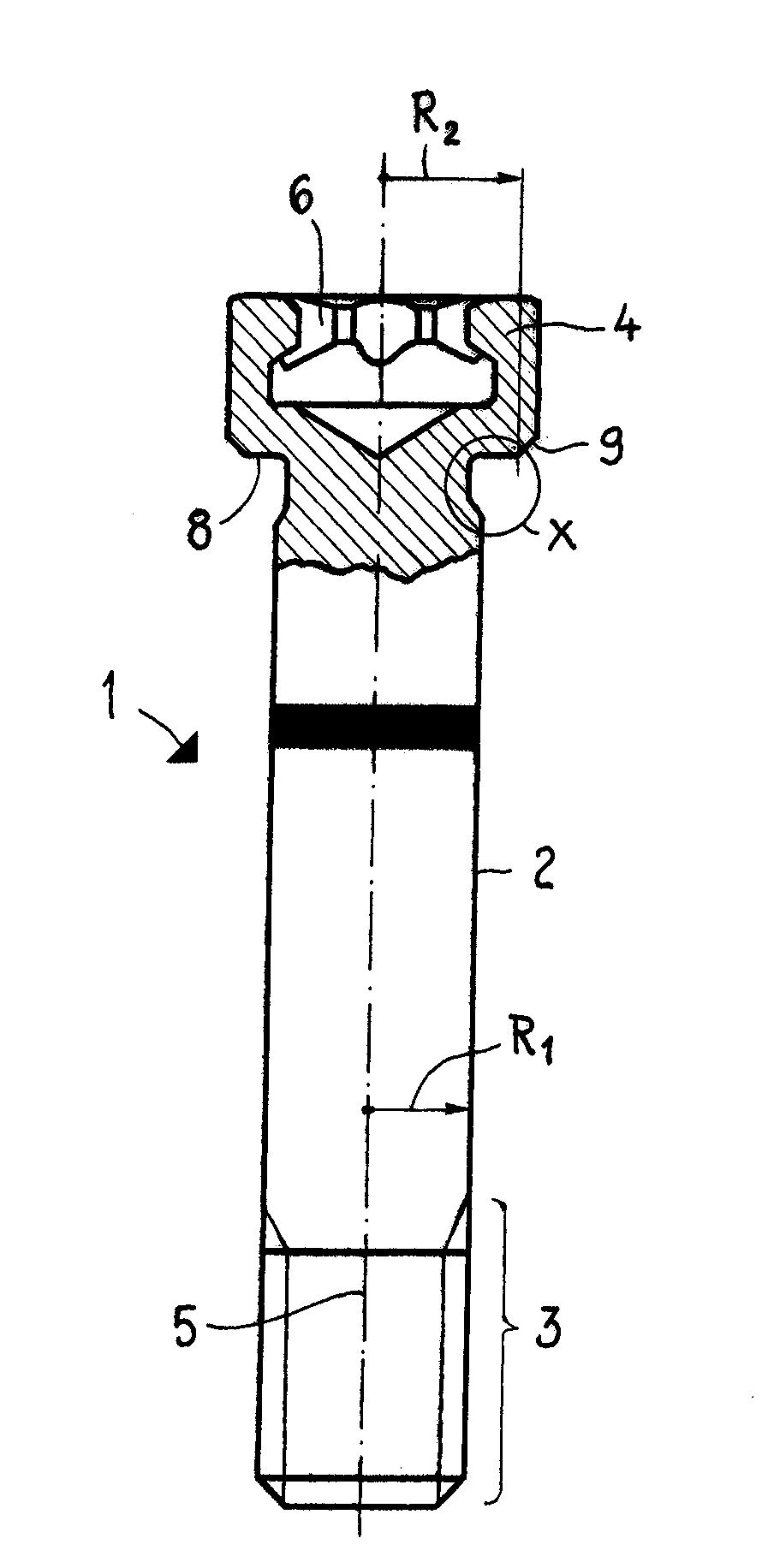

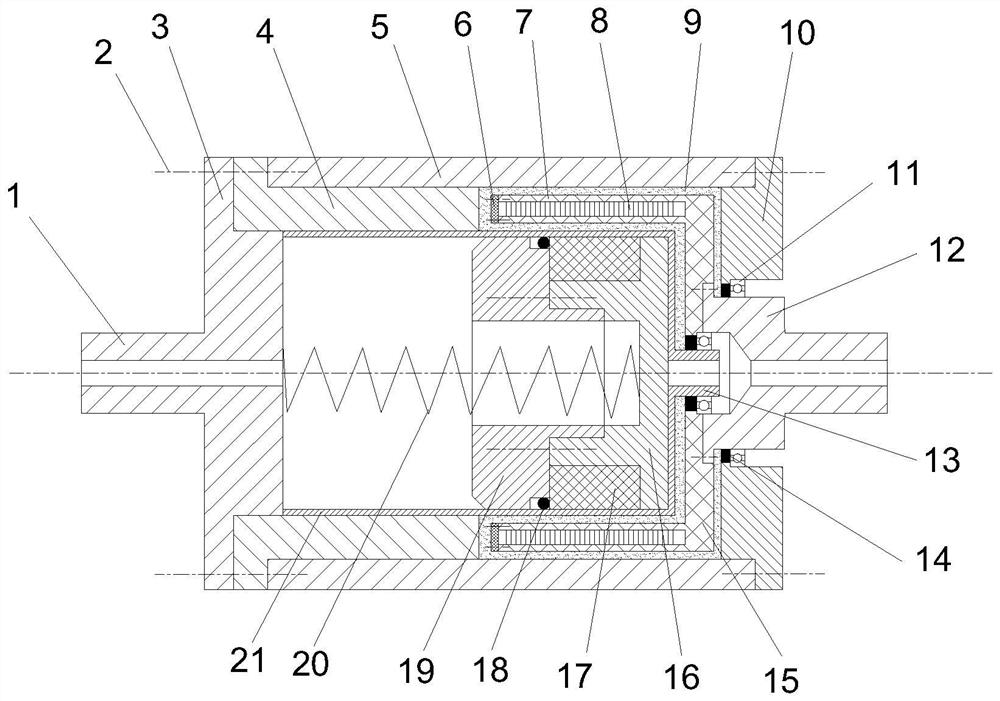

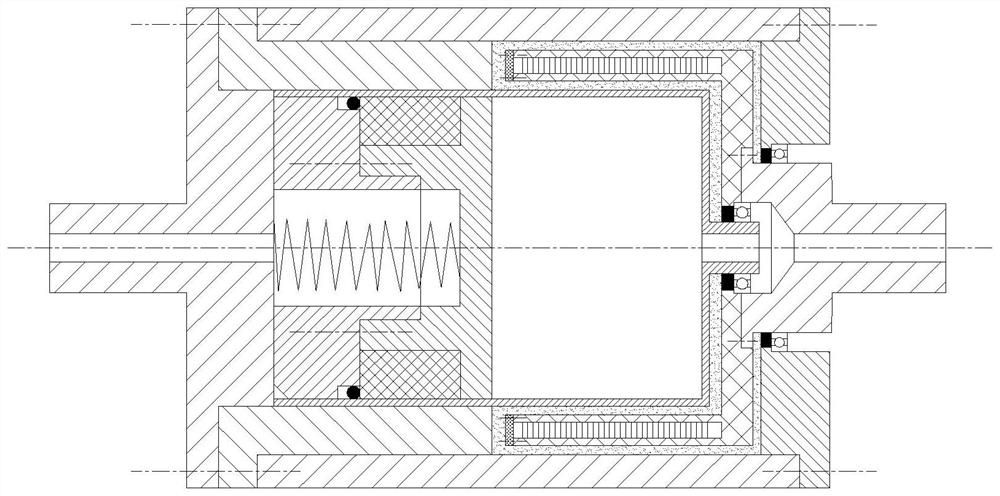

Electric machine and method for assembling an electric machine

The invention relates to an electric machine (1), comprising a drive shaft (2), on which a rotor (3) and a connecting element (4) are arranged, at least partially force-closed torque transmission connection being formed between the rotor (3) and the connecting element (4) in that the connecting element (4) is pushed in the direction of the rotor (3) by means of a locking element (18). The locking element (18) is designed as a screw and has an external screw thread (25), which is screwed into an internal shaft thread (26) of the drive shaft (2). The invention further relates to a method for assembling an electric machine (1).

Owner:SEG AUTOMOTIVE GERMANY GMBH

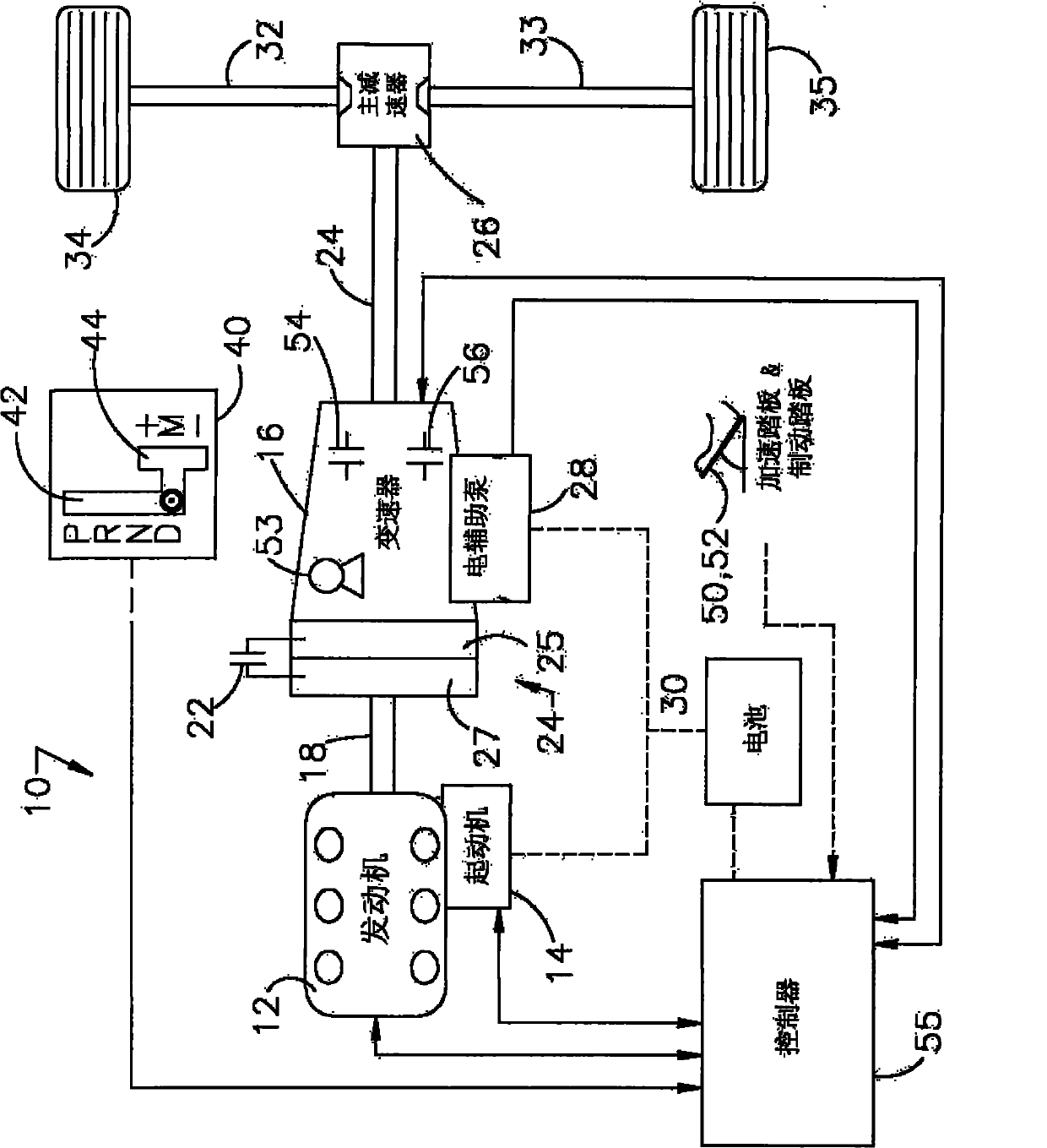

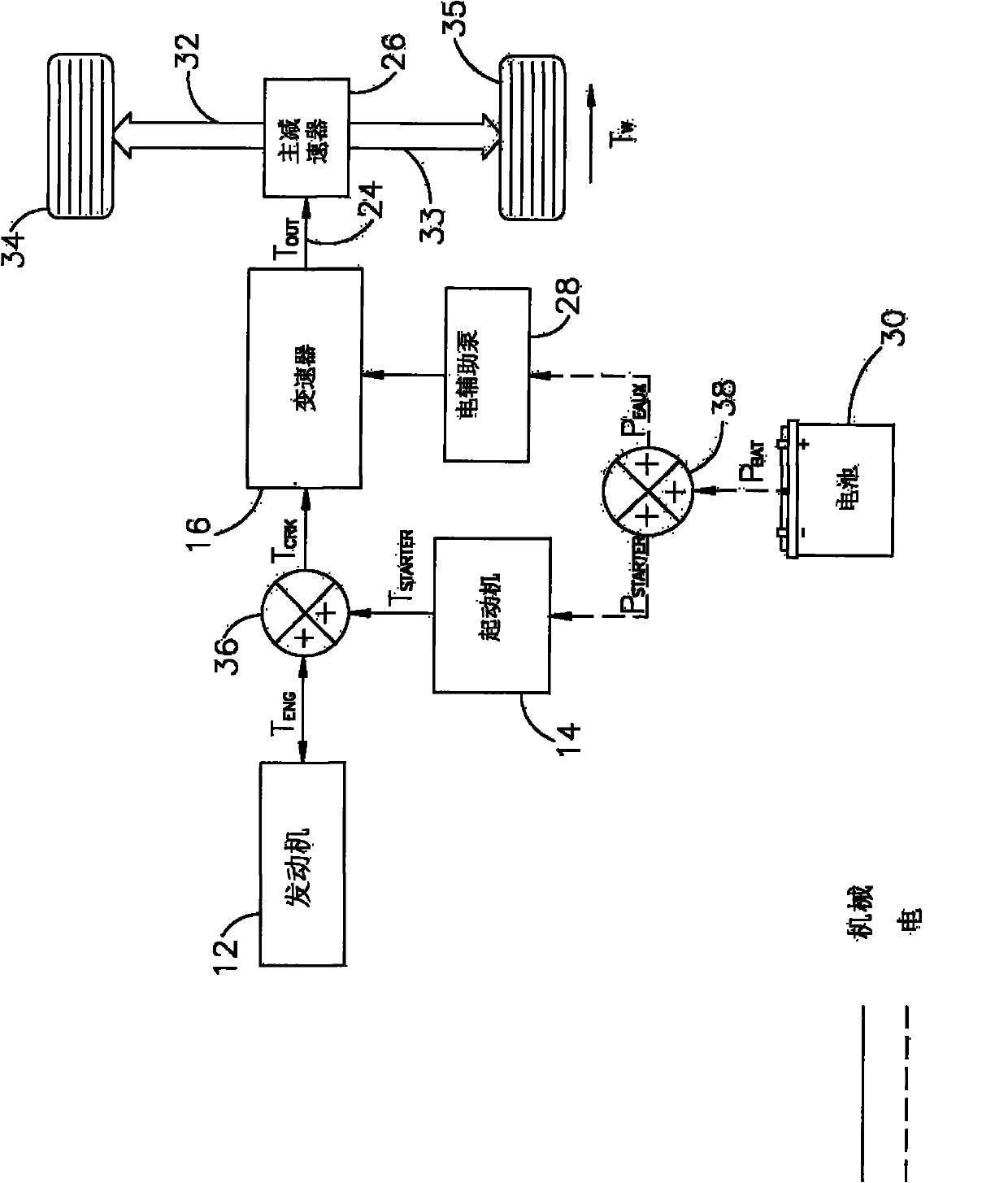

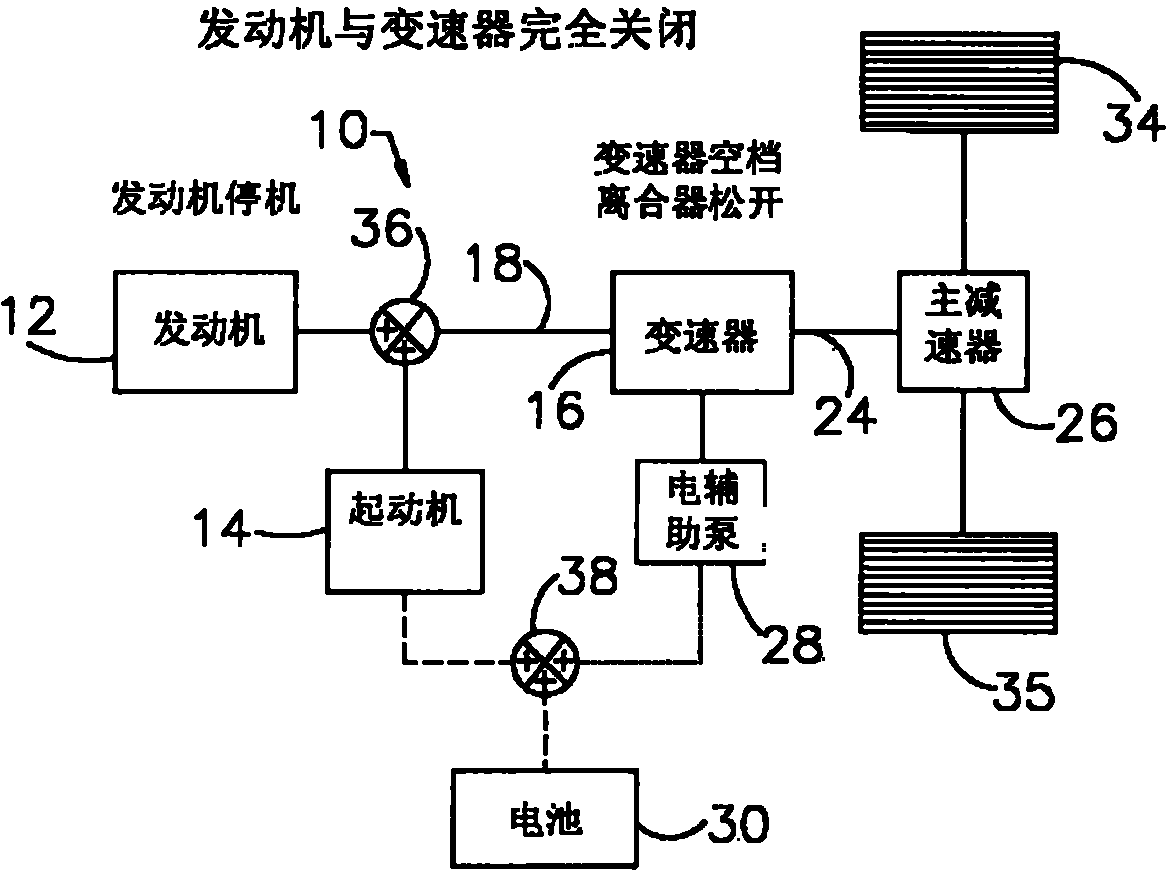

Method for restarting engine in hybrid electric powertrain

A method for restarting an engine in a hybrid electric powertrain includes using an auxiliary pump while the engine is shutdown to maintain stroke pressure in an oncoming transmission friction control element whose engagement is required to launch the vehicle following the restart, initiating an automatic engine restart, increasing a torque capacity of the control element while the engine is restarting, and using pressure produced by a transmission pump in the transmission to lock the control element after the engine restarts.

Owner:FORD GLOBAL TECH LLC

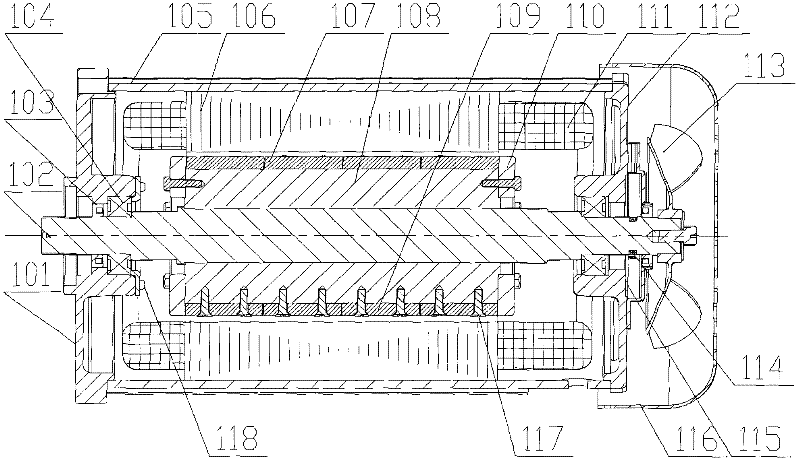

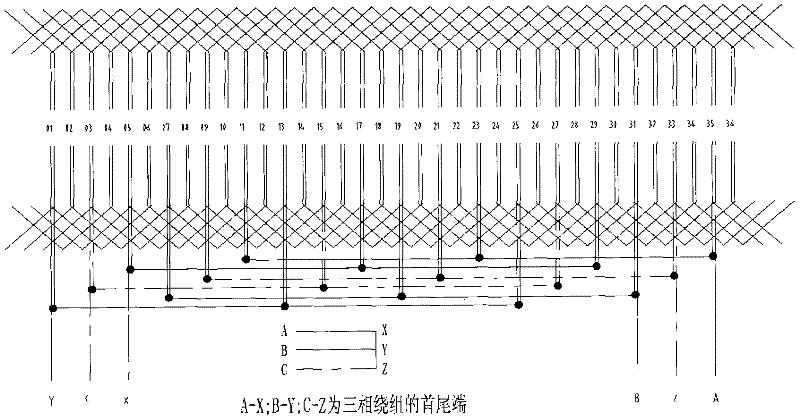

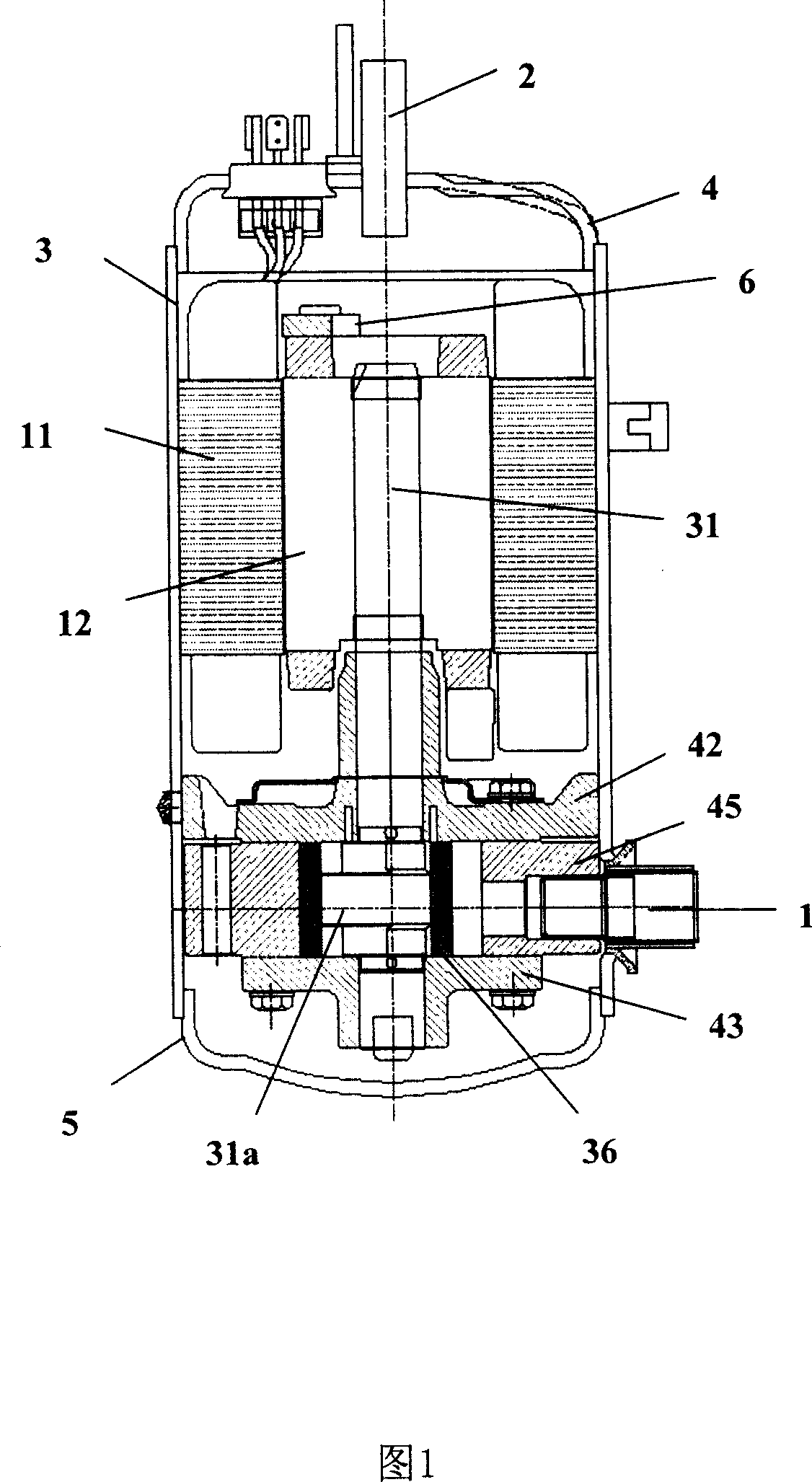

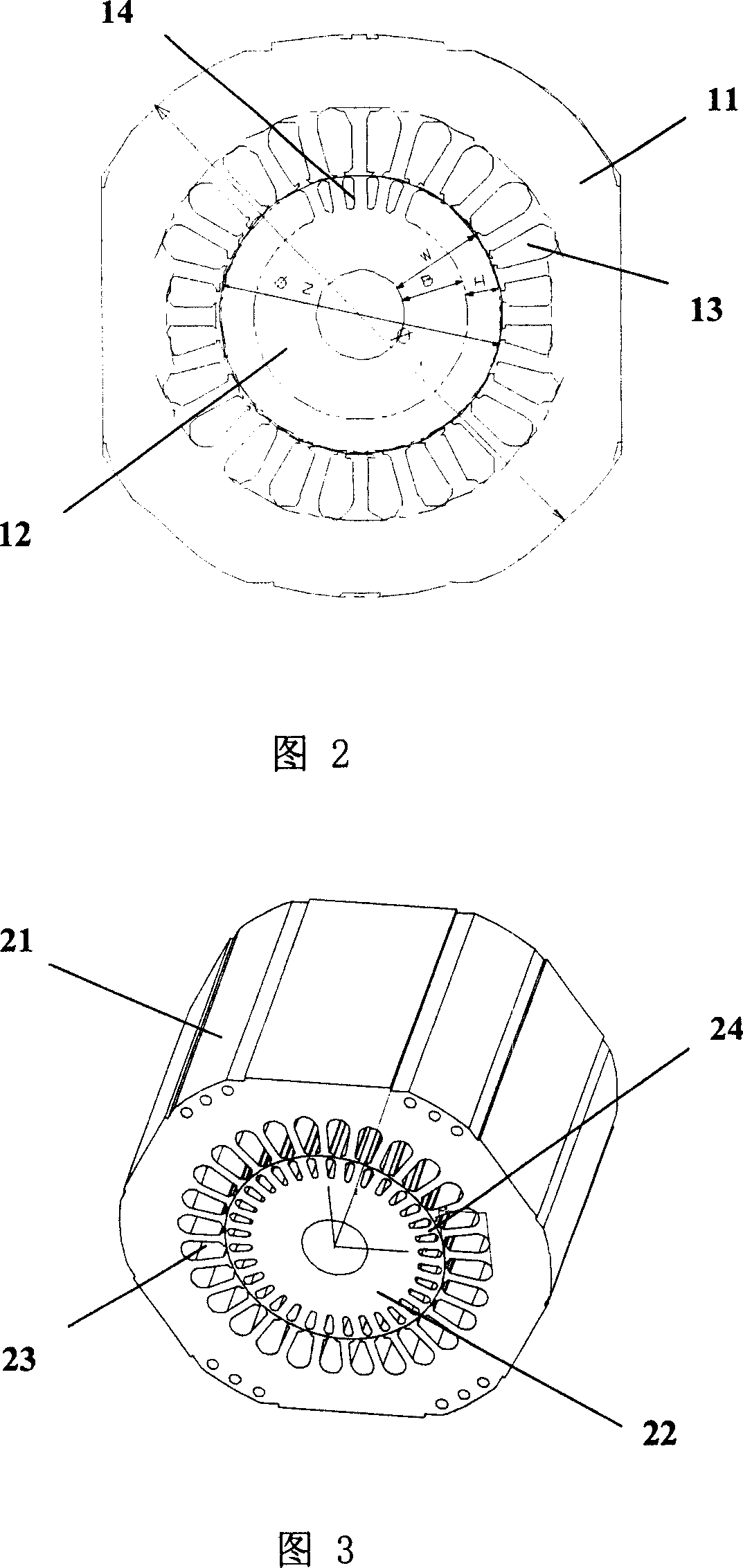

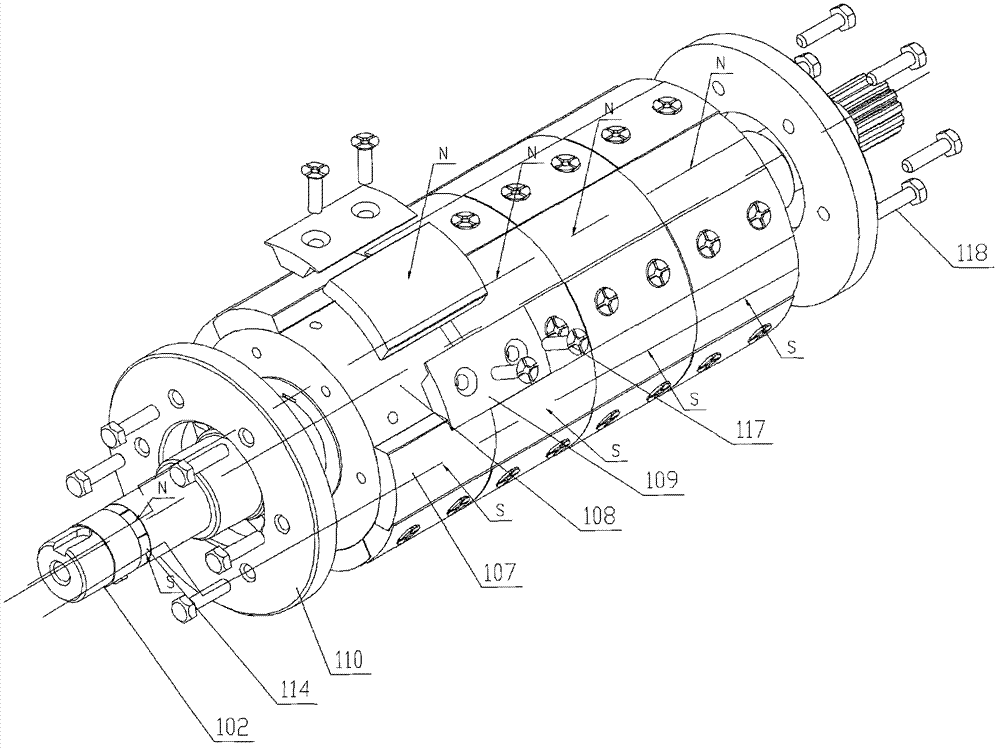

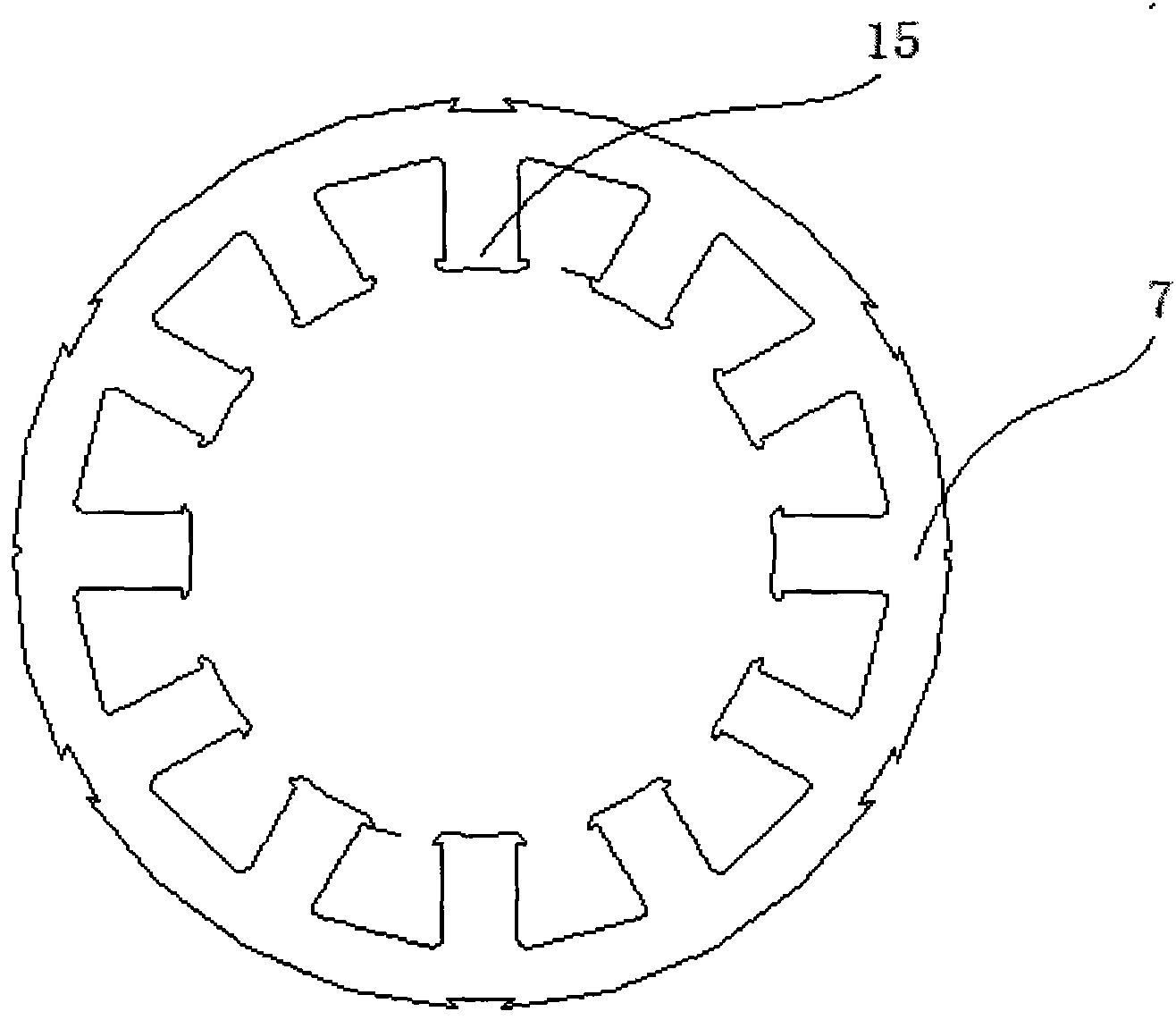

Electromechanical part of rotary compressor

InactiveCN1980004AReasonable distributionIncrease speedMagnetic circuit rotating partsMagnetic circuit stationary partsMaximum torqueEngineering

The electromechanical part is mainly composed of stator fixed on inner wall of cylindrical shell, and rotor located at center of the stator. Being in tubular structure, the stator includes 28 pieces of stator slots depressed on inner circle face. Rotor is in shape of cylinder. Multiple rotor slots are impenetrated to excircle circumference and distributed in rediatiform. Height of each rotor slot is 11mm. Number of stator slot is increased to 28 pieces from 24 pieces, and height of rotor slot is increased in the invention. Thus, magnetic field is distributed more reasonably, and rotating speed, and maximum torque are raised so as to reach optimal efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Self-locking centrifugal compressor impeller structure

PendingCN110017300AIncrease preloadImprove dynamic balance accuracyPump componentsPumpsInterference fitDynamic balance

The invention discloses a self-locking centrifugal compressor impeller structure, and relates to the technical field of compressor impeller structures. The technical problem of low connection reliability between an impeller and a rotor shaft of a centrifugal compressor in the prior art is solved. The self-locking centrifugal compressor impeller structure comprises an impeller and a rotor shaft, the end face of the impeller is provided with an outer conical surface, the end face of the rotor shaft is provided with an inner conical surface, the outer conical surface is connected with the inner conical surface through transition fit or interference fit, and the rotor shaft locks the impeller. Due to the fact that the impeller rotated at a high speed is expanded outwards under the action of self centrifugal force and work heating, the structural design that the outer conical surface of the impeller makes contact with the inner conical surface of the rotor shaft is added on the basis of seam allowance fit between the impeller and the rotor shaft in the prior art, the inner conical surface of the rotor shaft can limit the outward expansion effect of the outer conical surface of the impeller, so that dynamic balance precision in the working process of the rotor shaft and the impeller is favorably maintained, and the maximum transferable torque is improved.

Owner:上海优社动力科技有限公司

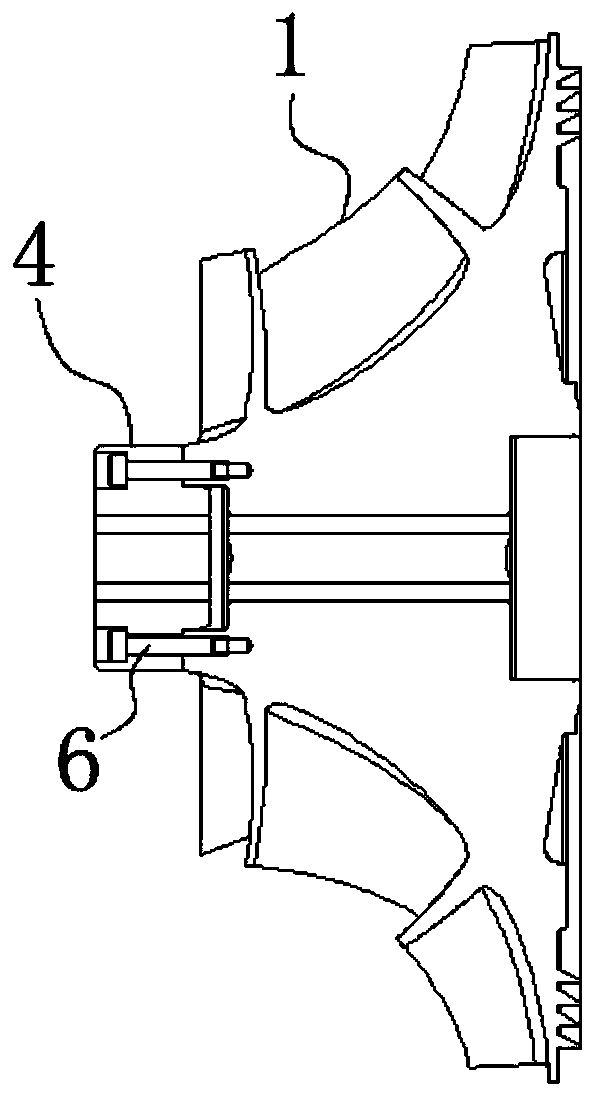

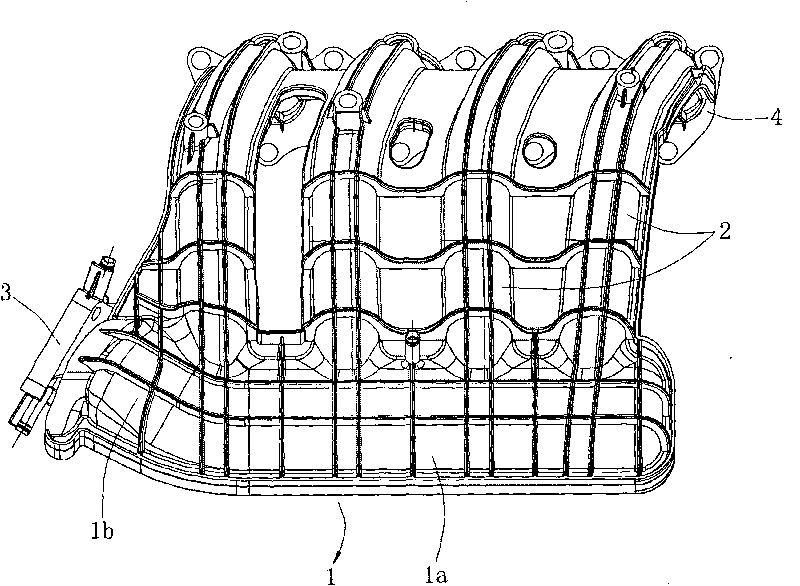

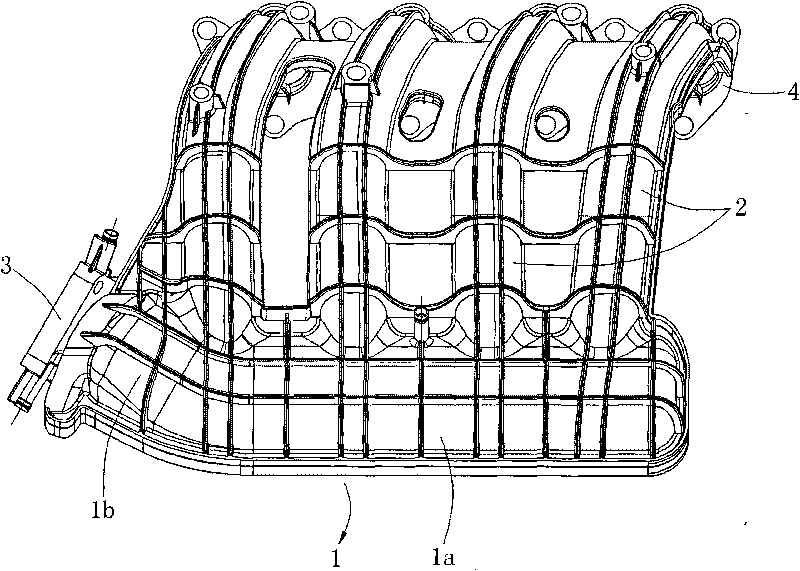

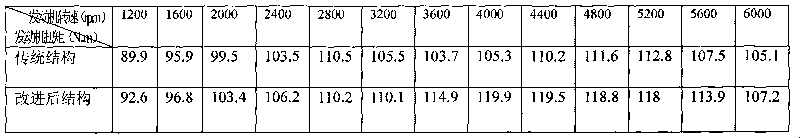

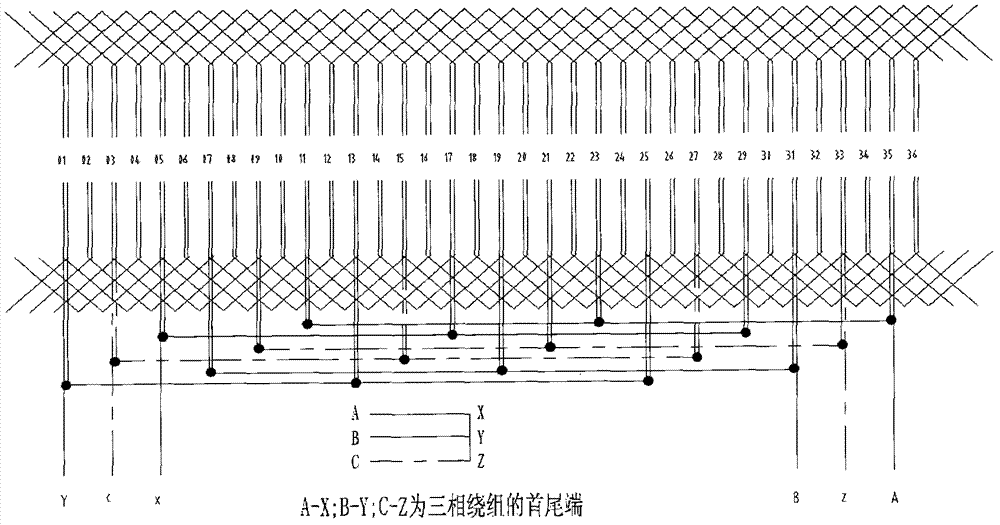

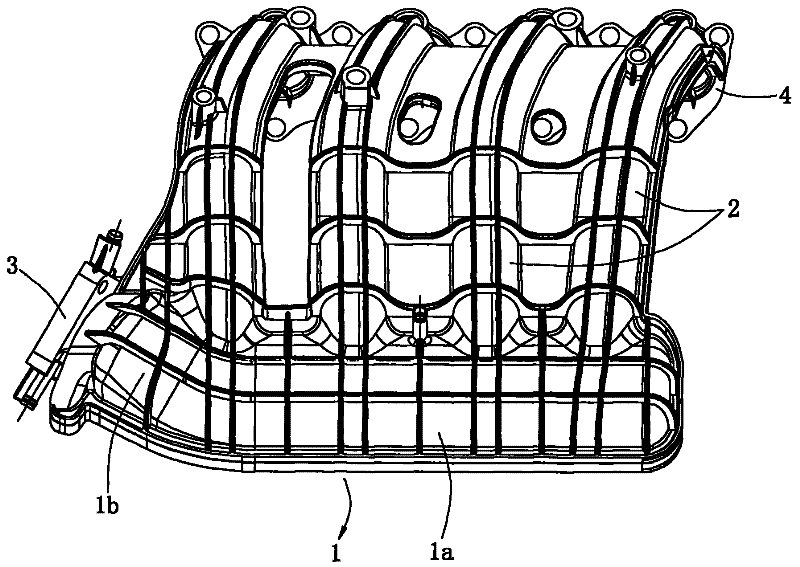

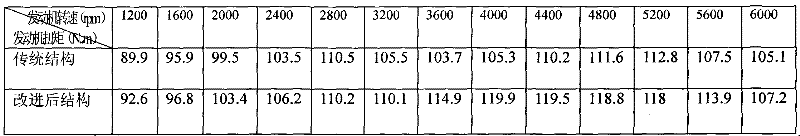

Automotive engine intake manifold

InactiveCN101705890AImprove inflation efficiencyImprove performanceCombustion-air/fuel-air treatmentMachines/enginesStraight segmentPower performance

The invention discloses an automotive engine intake manifold. A voltage-stabilizing cavity consists of a straight segment and an oblique upturned inlet manifold; the inlet manifold is connected with a throttle valve installation flange; a plurality of air inlet bent pipes are connected between the straight segment of the voltage-stabilizing and the installation flange of a cylinder cover, wherein, the quantity of the air inlet bent pipes is equal to that of the cylinders; a 145-155 degrees of included angle is arranged between the axes of the straight segment of the voltage-stabilizing and the inlet manifold; each air inlet bent pipe has the same shape and the same length, the length of each air inlet bent pipe is 390-410mm, and the inner diameter thereof is 34-37mm. By changing the shape, length and inner diameter of the air inlet bent pipe, and the included angle between the axes of the straight segment of the voltage-stabilizing and the inlet manifold, the automotive engine intake manifold of the invention can greatly increase the volumetric efficiency of the cylinder, thus improving the power performance of the engine, so that the maximum power of the engine can be increased by 17%, and the maximum torque can be increased by 20%, thereby greatly reducing vibration and noise of the engine.

Owner:力帆科技(集团)股份有限公司

Permanent magnet brushless DC (direct current) motor

ActiveCN102364846BLarge magnet surface areaImprove the magnetic effectMagnetic circuit rotating partsMagnetic circuit stationary partsHall elementMagnetic poles

The invention discloses a permanent magnet brushless DC (direct current) motor which comprises a front end cover, a rear end cover, an enclosure, a stator, a rotor and a Hall element sensor circuit board, wherein the rotor comprises a rotor shaft, a rotor yoke, magnetic steels, magnetic steel baffles and magnetic steel clapboards; the rotor yoke is not provided with a rotor sheet; the magnetic steels are fixed on the outer periphery of the rotor yoke and are shielded by the magnetic steel baffles positioned at both ends of the rotor yoke; and the magnetic clapboards are arranged between the magnetic steels with different magnetic poles. In the invention, the rotor is not provided with the rotor sheet, so that the rotor has a more reasonable structure and the rotor sheet does not need to be formed in the machining process, and thus, the permanent magnet brushless DC motor is convenient to process, is simple to assemble and is firmer to fix the magnetic steels.

Owner:ZHEJIANG ACTIVETECH COMP TECH CO LTD

car engine intake manifold

InactiveCN101705890BAvoid sharp bendsSpeed up the flowCombustion-air/fuel-air treatmentMachines/enginesMaximum torqueCylinder head

The utility model relates to an intake manifold of an automobile engine. The pressure-stabilizing chamber is composed of a straight section and an intake manifold that is inclined upwards. A plurality of intake elbows are connected between them, and the number of intake elbows is equal to the number of cylinders, and the axis of the straight section of the pressure-stabilizing chamber and the axis of the intake manifold have an included angle of 145-155°; The shape and length of each intake elbow are the same, and the length of each intake elbow is 390-410 mm, and the inner diameter is 34-37 mm. By changing the shape, length, inner diameter of the intake elbow, and the angle between the axis of the straight section of the pressure-stabilizing chamber and the axis of the intake manifold, the invention can greatly improve the charging efficiency of the cylinder, thereby improving the power performance of the engine. The maximum power of the engine can be increased by 17%, the maximum torque can be increased by 20%, and the vibration and noise of the engine can be greatly reduced.

Owner:力帆科技(集团)股份有限公司

A kind of nano silicon dioxide with surface grafted polyisoprene, preparation method and application thereof

Owner:安徽凯得兴汽车零部件科技有限公司

Motor and method for assembling the motor

The invention relates to an electric machine (1), comprising a drive shaft (2), on which a rotor (3) and a connecting element (4) are arranged, an at least partially force-closed torque transmission connection being formed between the rotor (3) and the connecting element (4) in that the connecting element (4) is pushed in the direction of the rotor (3) by means of a locking element (18). The locking element (18) is designed as a screw and has an external screw thread (25), which is screwed into an internal shaft thread (26) of the drive shaft (2). The invention further relates to a method for assembling an electric machine (1).

Owner:SEG AUTOMOTIVE GERMANY GMBH

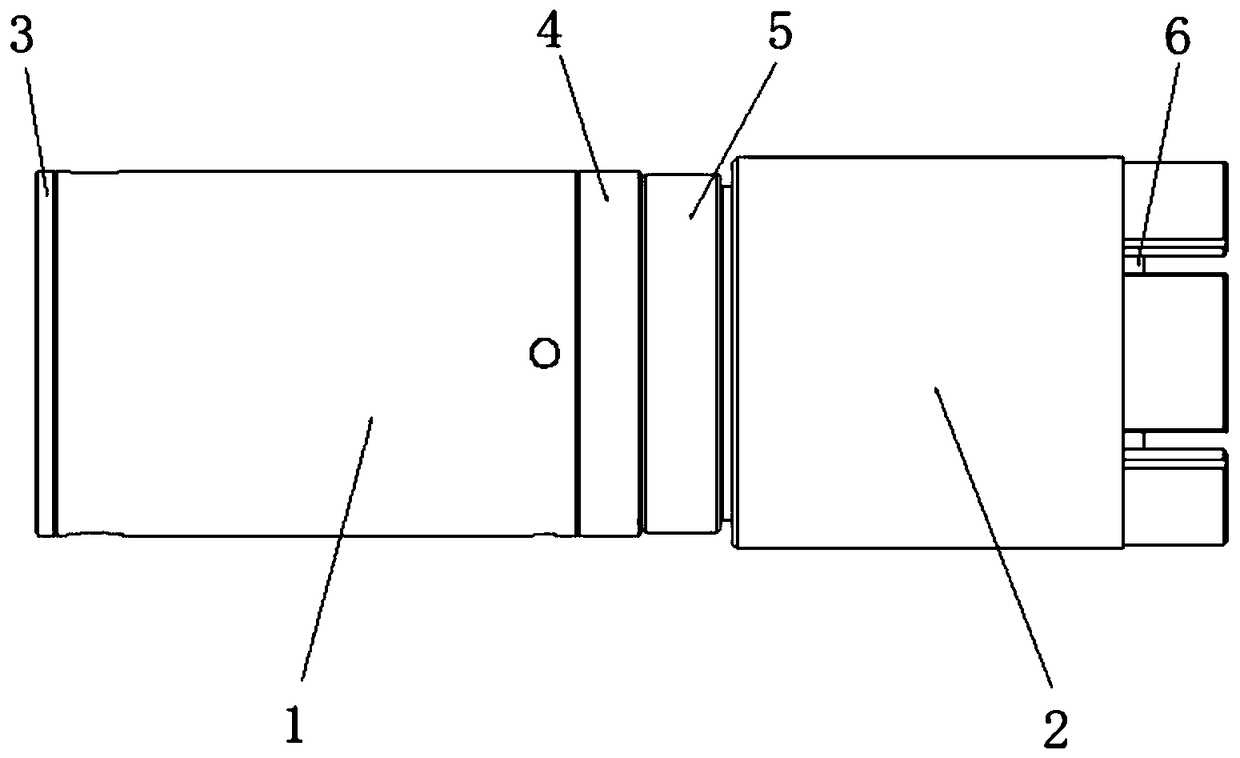

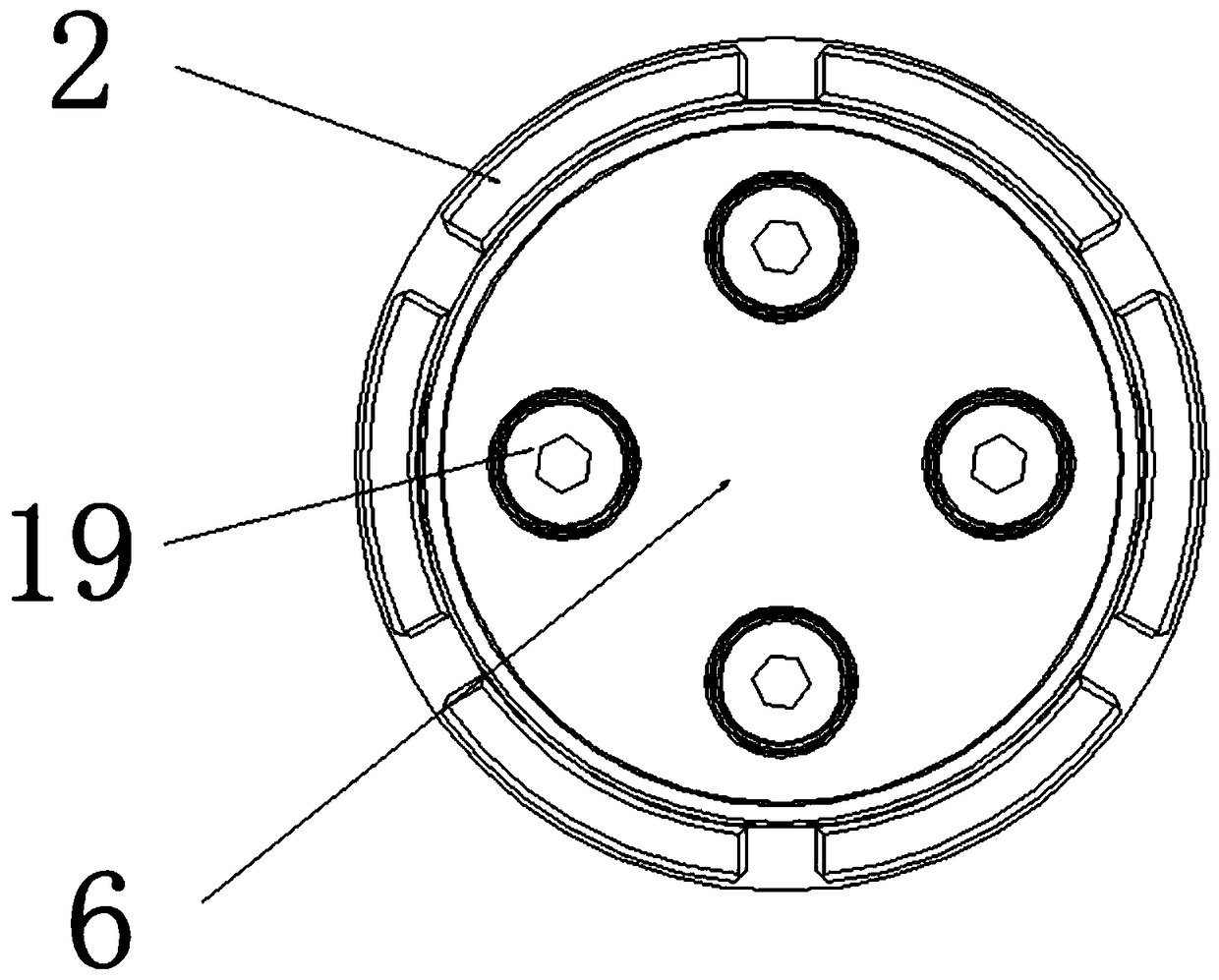

Universal coupling

The present invention proposes a universal joint, which includes an intermediate shaft with an intermediate fork at both ends and two connecting forks adapted to the intermediate fork, and also includes a joint for connecting the intermediate fork and the load-bearing ring assembly of the connecting yoke, the intermediate yoke and the connecting yoke are oppositely provided with two coaxially arranged trunnions, and the load-bearing ring assembly is provided with two groups for the middle The pair of holes into which the trunnion on the fork and the connecting fork are inserted, the axes of the two groups of pair of holes are perpendicular to each other, and a bearing cooperating with the trunnion is arranged in the pair of holes. The universal coupling of the present invention replaces the original cross shaft with a load-bearing ring assembly, and sets the bearing on the load-bearing ring assembly, which can avoid the limitation of the size of the fork head, and can choose a larger-sized bearing, so it has the advantages of High load capacity, the maximum torque can be increased by 20% to 30%.

Owner:TAIYUAN HEAVY IND

Excavator walking condition adaptive control system, control method and excavator

ActiveCN109024752BWalk fastIncreased maximum torqueSoil-shifting machines/dredgersMaximum torqueSolenoid valve

The invention discloses a self-adaptive control system and control method for excavator walking conditions, comprising a pressure sensor arranged on the walking pilot valve, a main controller arranged on the frame, and a Adaptive mode switch, proportional solenoid valve set on the main pump. When the adaptive mode switch is set to ON, the pressure sensor collects the pilot pressure of the travel pilot valve and transmits this signal to the main controller. The main controller detects the current pilot pressure and the working mode of the main pump. When the pilot pressure ≥ At 8bar, the main controller outputs corresponding instructions according to the current working mode of the main pump. The invention automatically recognizes the running conditions through the system, and automatically increases the power of the main pump in the light-load mode, thereby increasing the flow supplied to the walking motor, increasing the walking speed of the excavator, shortening the walking time, and improving work efficiency; on the other hand, the flow The increase increases the maximum torque of the travel motor.

Owner:XCMG EXCAVATOR MACHINERY

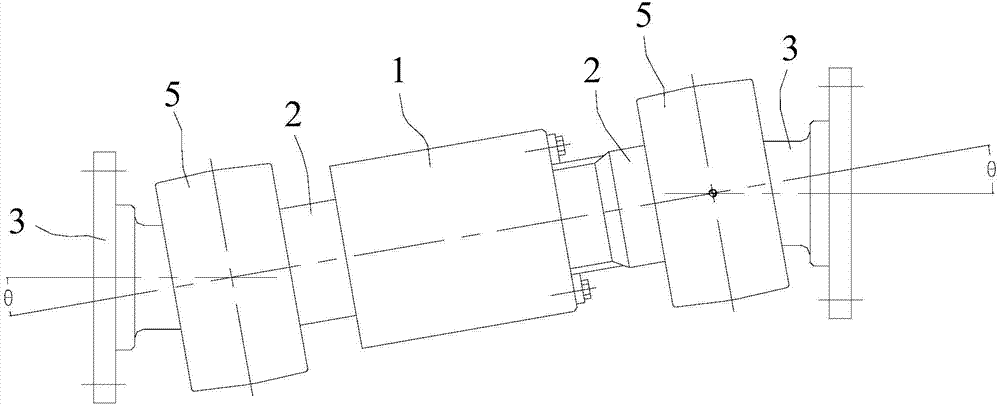

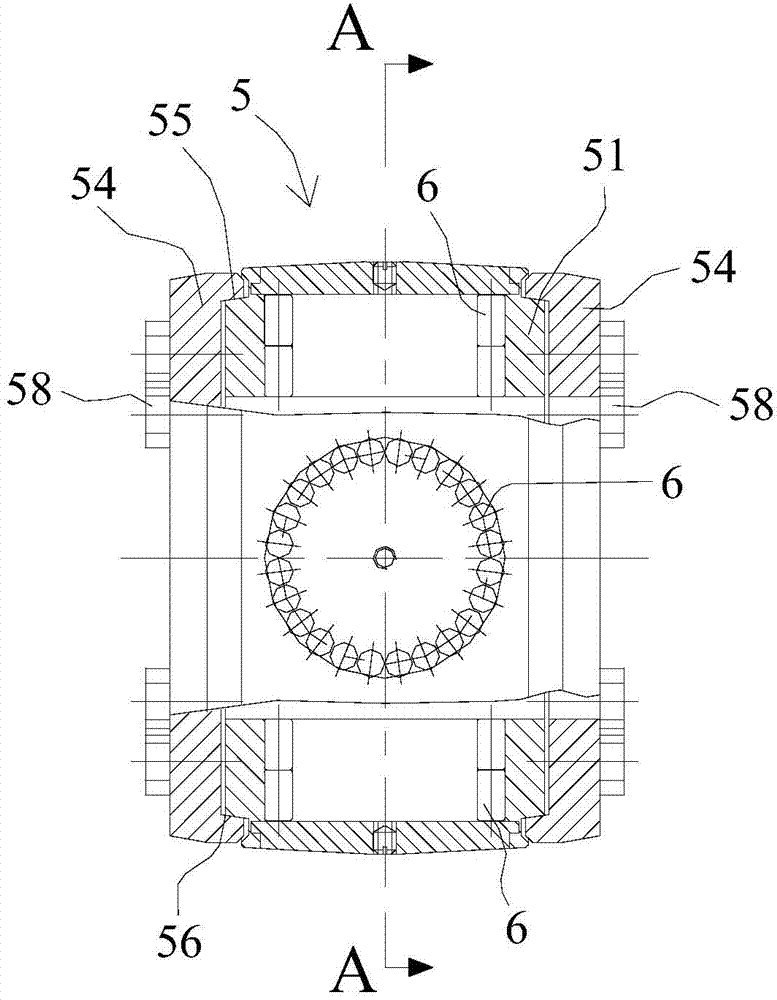

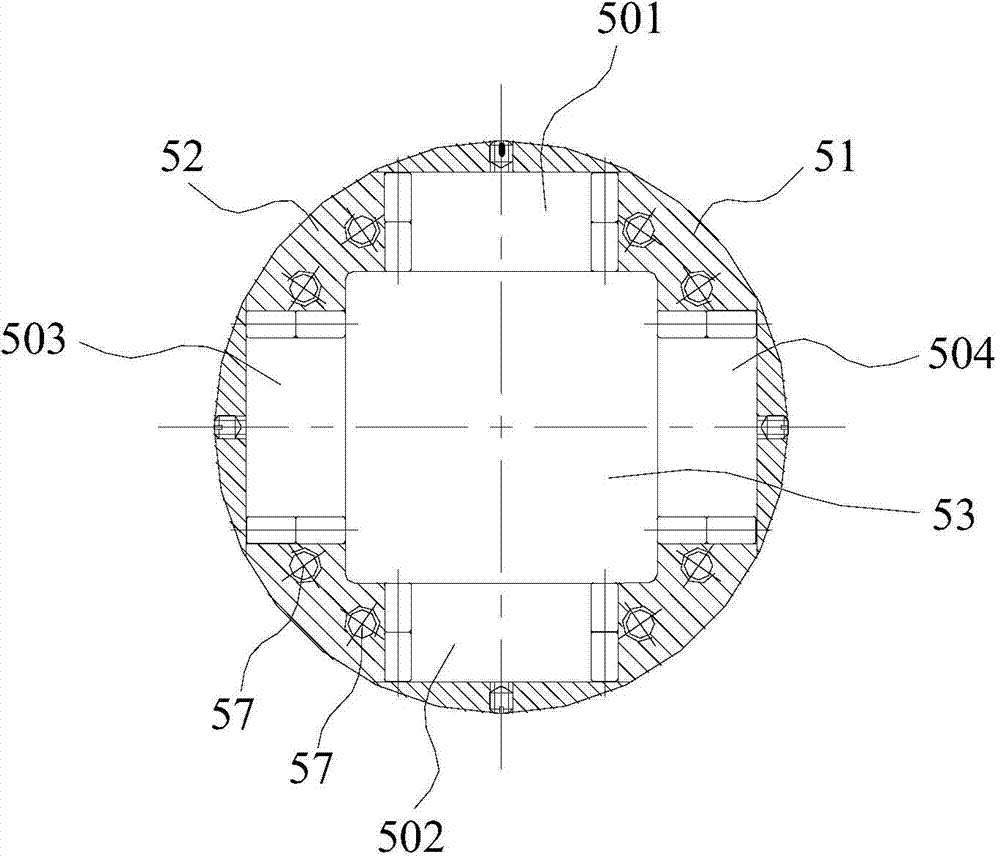

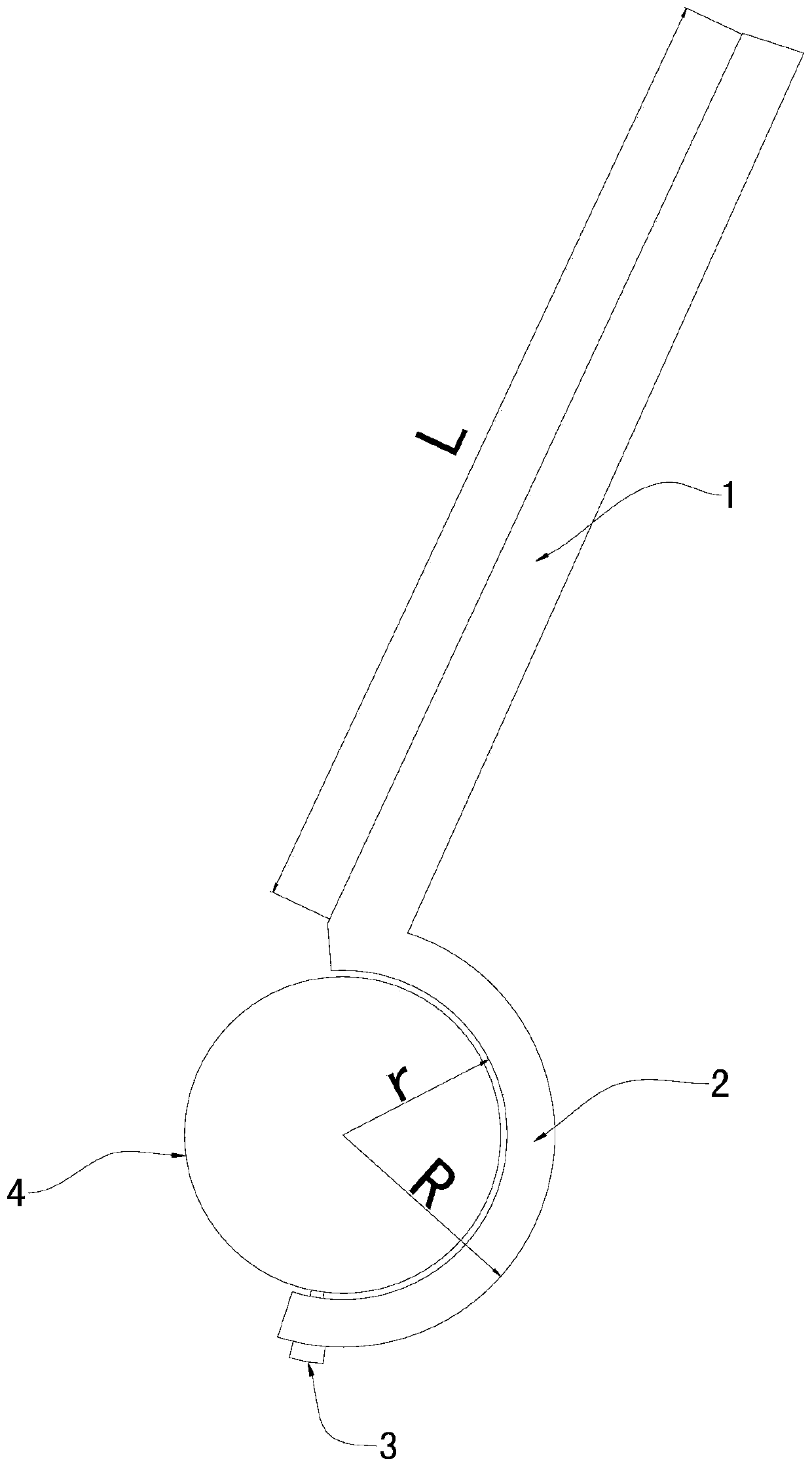

Universal coupling

The invention provides a universal coupling which comprises an intermediate shaft, two connecting jaws and force bearing ring assemblies. Two intermediate jaws are respectively arranged at two ends of the intermediate shaft, the two connecting jaws are matched with the intermediate jaws, the force bearing ring assemblies are used for being connected with the intermediate jaws and the connecting jaws, two trunnions which are coaxially arranged are oppositely arranged on each of the intermediate jaws and the connecting jaws, two groups of paired holes are respectively formed in each force bearing ring assembly, the trunnions on the intermediate jaws and the trunnions on the connecting jaws can be inserted into the paired holes, the axes of the two groups of paired holes in each force bearing ring assembly are perpendicular to each other, and bearings which are matched with the trunnions are arranged in the paired holes. The universal coupling has the advantages that the original cross shafts are replaced by the force bearing ring assemblies, the bearings are arranged on the force bearing ring assemblies, accordingly, the jaws are free of dimensional constraints, the large bearings can be selectively utilized, the universal coupling is high in bearing capacity, and the maximum torque borne by the universal coupling can be increased by 20%-30%.

Owner:TAIYUAN HEAVY IND

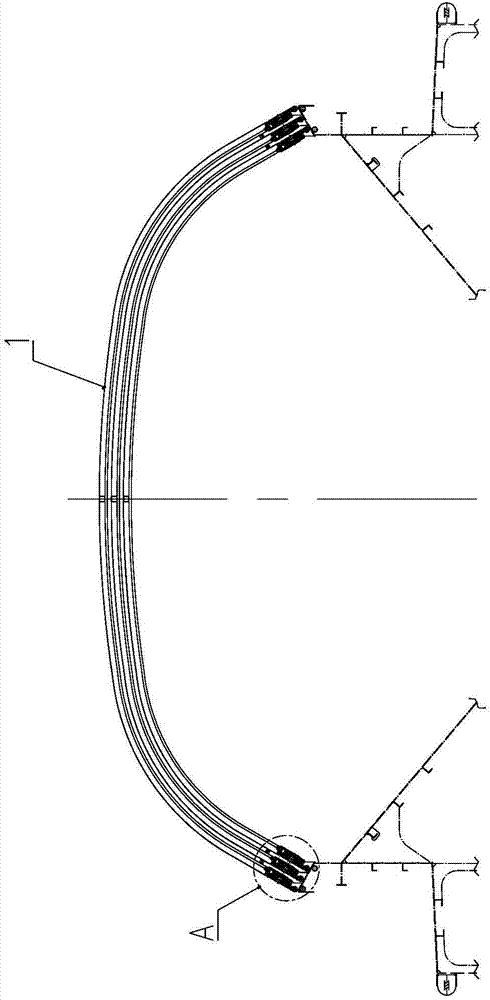

Telescopic cylinder piston rod thread fastening wrench

The invention provides a telescopic cylinder piston rod thread fastening wrench. The telescopic cylinder piston rod thread fastening wrench comprises a handle, a holding hook and a fastening screw; the handle is provided with a first end and a second end in the length direction; the holding hook is shaped like an arc-shaped plate and provided with a first end and a second end in the circumferential direction, the first end of the holding hook is connected with the first end of the handle, and the curvature radius of the inner circumferential wall of the holding hook is matched with the radiusof a telescopic cylinder piston rod; and the fastening screw is used for circumferentially fixing the holding hook and the telescopic cylinder piston rod and arranged at the second end of the holdinghook in a threaded penetrating manner in the radial direction of the holding hook. According to the telescopic cylinder piston rod thread fastening wrench, the telescopic cylinder piston rod thread fastening wrench can stretch into a narrow space on the premise that a telescopic cylinder is not dismounted and taken out, and a threaded structure between the telescopic cylinder piston rod and corresponding other parts can be quickly fastened.

Owner:MCC BAOSTEEL TECH SERVICE

A pair plate of anti-deformation liquid-viscous speed-regulating clutch

InactiveCN105041911BStable jobIncrease contact areaFluid clutchesFriction liningViscous liquidThermal deformation

The invention provides a anti-deformation anti-deformation liquid-viscous speed-regulating clutch dual plate, the clutch dual plate is an annular steel sheet with a thickness of 2-5mm, and the inner ring or outer ring of the annular steel sheet is provided with The spline tooth is characterized in that the working surface of the clutch pair is wavy, and the working surface of the clutch pair is uniformly distributed with concentric annular grooves along the radial direction, and has diameters evenly distributed along the circumferential direction. To the rectangular groove. The invention improves the heat dissipation conditions of the friction pair, enhances the film-forming ability and dynamic pressure bearing capacity of the viscous liquid medium between the friction pairs, reduces the thermal deformation of the pair plate of the liquid-viscous speed-regulating clutch, prevents the phenomenon of band discharge, and improves the The working performance of the liquid-viscous speed-regulating clutch prolongs the service life of the liquid-viscous speed-regulating clutch.

Owner:JIANGSU UNIV

Composite fuel for automobile engine

InactiveCN100393855CGood compatibilityBoost octaneLiquid carbonaceous fuelsSolventOleic Acid Triglyceride

The invention relates the car engine composite fuel, comprising 30-90% petrol, 10-70% methanol, 0.5 -3% assisting solvent. The assisting solvent comprises 30-60% oleic acid or naphthenic acid or lactic acid, 1-3% orthotoluidine or triethylamine, 806-11% tuwen, 25-63% benzene, and 1% anhydrous sodium sulfate. The product is environmental protection and cleaning. The methanol petrol fuel reduces CO and HC concentrations in vehicle exhaust gas, cleaning air and improving contamination condition. The invention has advantages of simple technology and low cost.

Owner:么居标

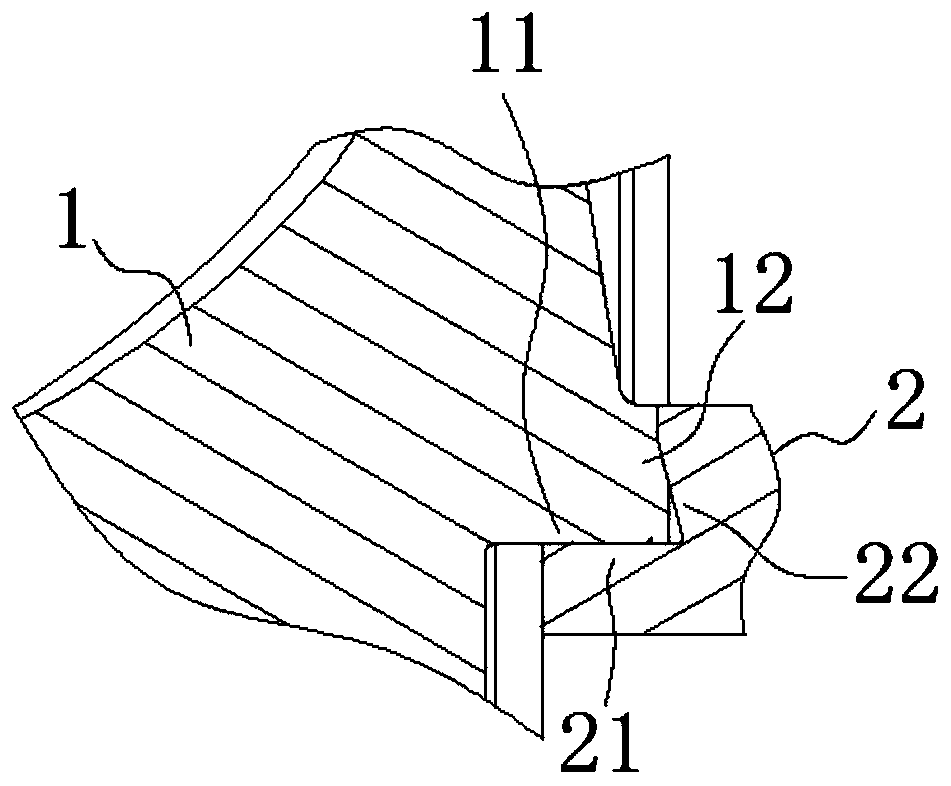

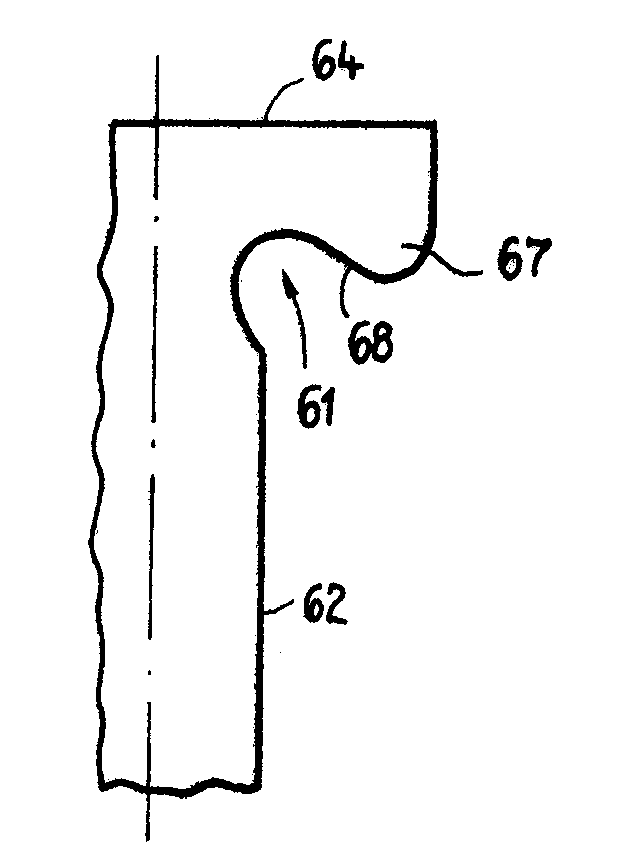

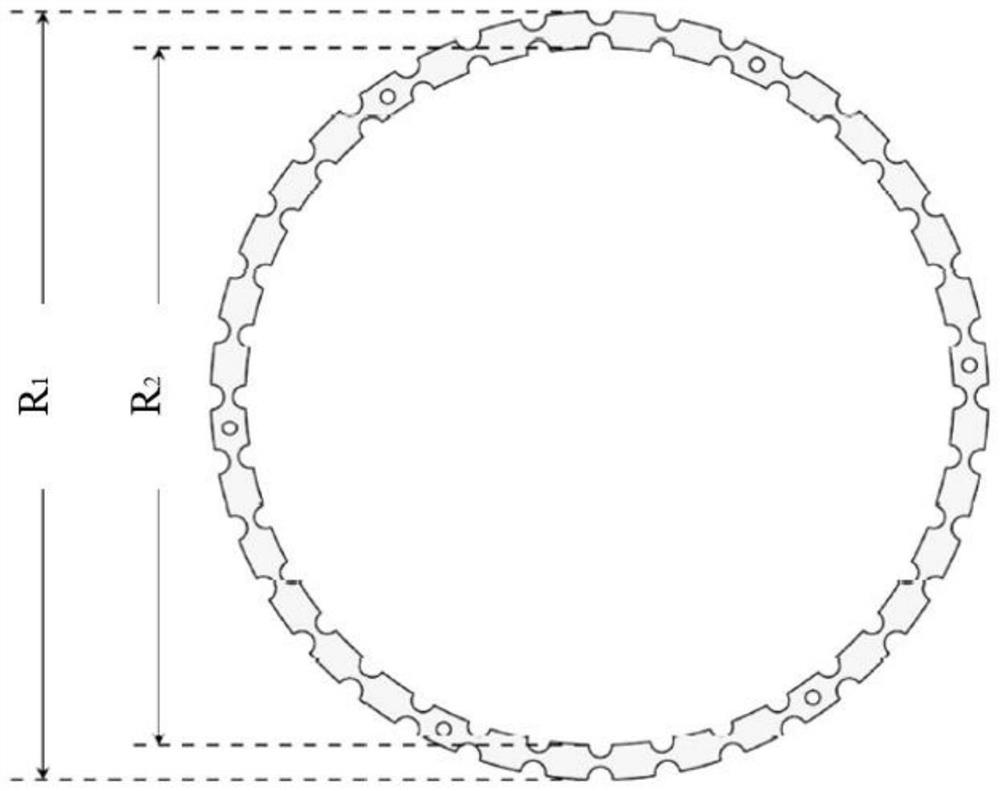

Improved screw head

ActiveCN102551902AIncreased maximum torqueReduce the incidence of failureDental implantsLoad modified fastenersAbutmentEngineering

A fastening system according to the present invention comprises a screw component (10) and a seating component (20). The screw component comprises a shaft (12) extending along a longitudinal axis (5) and having a maximum radius R 1 , said shaft comprising a threaded section (13), said screw component further comprising, at one end of the screw shaft, a head (14), the head comprising a bottom end (15) having a larger maximum radius R 2 than the screw shaft such that an exposed underside (18) of the screw head extends radially beyond the maximum radius of the screw shaft. The seating component comprises a screw channel (21) comprising a planar screw seat (22) having a minimum radius R 3 which is equal to or greater than R 1. The bottom end of the screw head comprises an annular contact surface for abutment against said screw seat, the contact surface being formed by the distal end of at least one downwardly extending protrusion (17) on the underside of the screw head, wherein the annular contact surface has a minimum radius greater than the minimum radius of the screw seat.

Owner:STRAUMANN HLDG AG

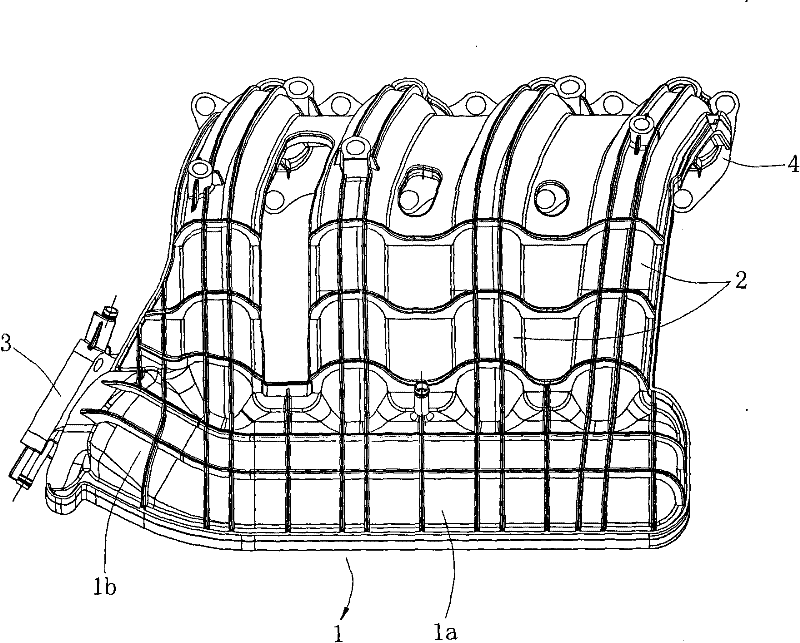

Switched reluctance motor for electric vehicle

InactiveCN104348324AImprove operational efficiencyRun fastElectric machinesDynamo-electric machinesBrushless motorsReluctance motor

The present invention discloses a switched reluctance motor for an electric vehicle. The switched reluctance motor comprises a gear box cover, a gear baffle plate, a center gear, a front cover, a rotor, a motor shell, a stator, a back cover, a Hall sensor, a blade cover, a fan and a fan cover which are orderly arranged from front to back. The switched reluctance motor is characterized in that the top cross section of inner teeth is wider than that of a column body, and the connection surface of each two tooth roots of the outer teeth of the stator is in the shape of an inward taper. According to the motor, through arranging rotor and stator structures which are mutually embedded, the operation efficiency is higher than that of a traditional series excited motor and a brushless DC motor, the loss is lower than that of an existing motor, the cost is lowest, the enamelled wire dosage of a coil is reduced for 1 / 3 to 1 / 2 compared with that of the series excited motor, and the adjustability is higher than that of the traditional series excited motor and brushless DC motor. The switched reluctance motor has the advantages of long-term continuous operation and stable and reliable quality.

Owner:唐志新

Double-shear magneto-rheological clutch under permanent magnet excitation

The invention discloses a double-shear magneto-rheological clutch under permanent magnet excitation. The double-shear magneto-rheological clutch comprises an output shaft, an outer shell, an input rotary drum shell, an input rotary drum core, magneto-rheological glue, an end cover, an input shaft, an inner shell shaft, an input rotary disc, a permanent magnet, a permanent magnet end cover and an inner shell. The inner shell is mounted in a cavity formed by the output shaft end cover, the sleeve, the outer shell and the end cover; a whole formed by connecting the permanent magnet, the permanent magnet sleeve and the permanent magnet end cover is mounted in the inner shell; one end of the spring is connected with the permanent magnet sleeve, and the other end is connected with the output shaft end cover; the input rotating drum shell is fixedly connected with the input rotating disc, and the input shaft is fixedly connected with the input rotating disc. The inner shell shaft is fixedly connected with the inner shell; the input rotary drum core is embedded into the input rotary drum shell, and the input shaft and the end cover are connected through a bearing to form a rotating pair. The magneto-rheological gel is adopted as a force transmission medium, the permanent magnet is adopted as an excitation source, the torque is controllable, the automatic fault prevention function is achieved, magnetic field excitation energy consumption is avoided, and the structure is simple.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com