Hatch cover mechanism suitable for full-electric propulsion bulk cargo ship

An all-electric technology for bulk carriers, applied to power control mechanisms, wing leaf control mechanisms, ship hatches/hatches, etc., can solve problems that do not meet environmental protection requirements, heavy workload, and long time consumption, and achieve The effect of uniform internal force, improved power, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

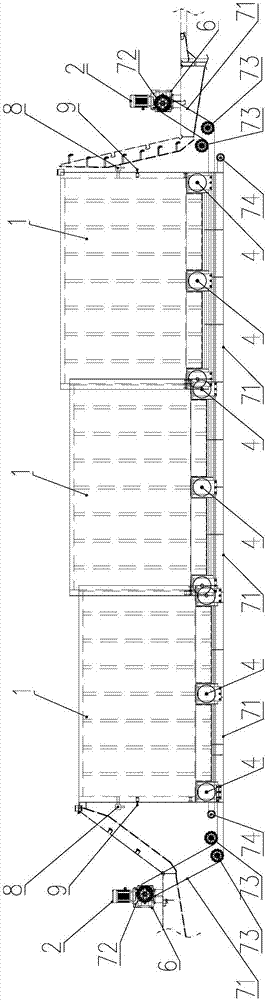

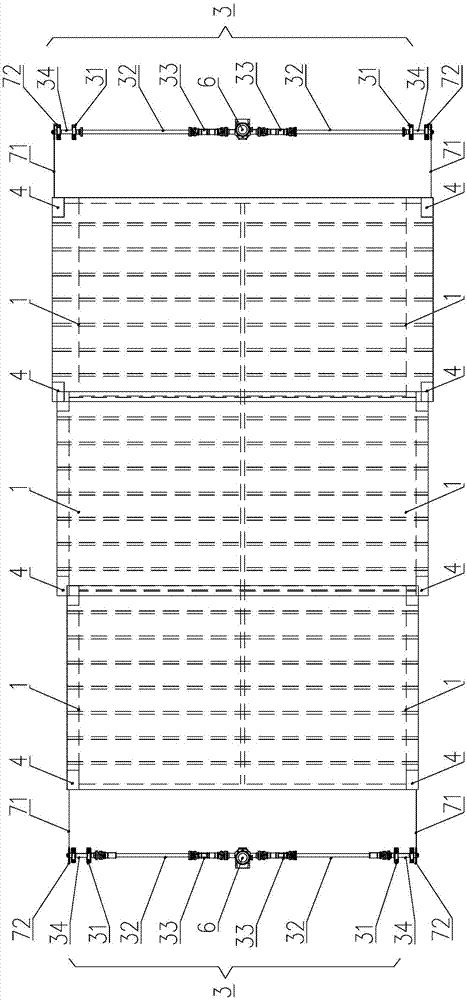

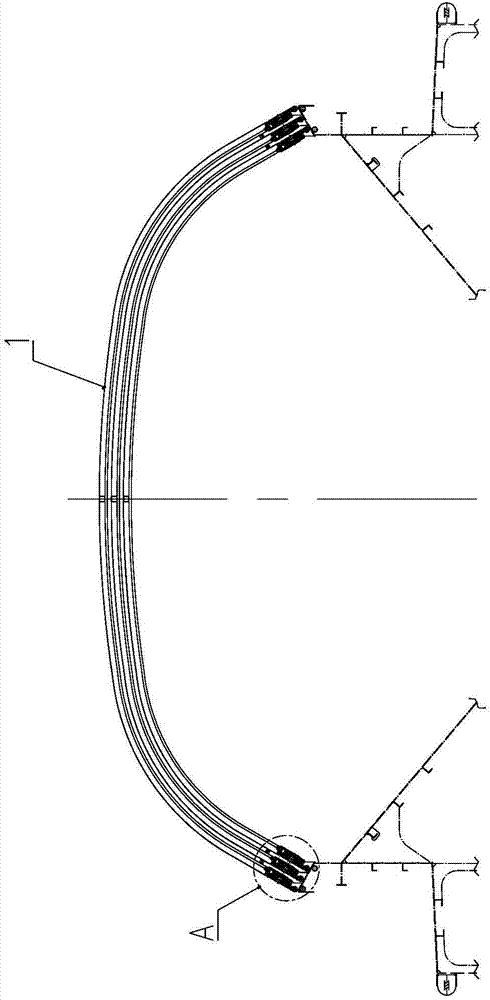

[0055] Such as figure 1 and figure 2 As shown, a hatch cover mechanism suitable for all-electric propulsion bulk carriers is located on the main deck, including hatch cover 1, and also includes:

[0056] The electric motor 2 is located at both ends of the hatch cover 1 and provides the operating power of the hatch cover mechanism;

[0057] The traction device is located on the left and right sides of the hatch cover 1, and drives the hatch cover 1 to move forward or aft;

[0058] At least four sets of roller assemblies 4 are supported on the bottom of the hatch cover 1;

[0059] The track assembly 5 is located below the roller assembly 4, so that the hatch cover 1 is supported by the roller assembly 4 under the action of the traction device, and moves forward or rearward along the track assembly 5;

[0060] The control system is electrically connected with the traction device and is used to control the start or stop of the traction device.

[0061] In this technical solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com