Electric machine and method for assembling an electric machine

A connection method and drive shaft technology, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve the problems of damage to the drive shaft, the axial force cannot be arbitrarily increased, etc., and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

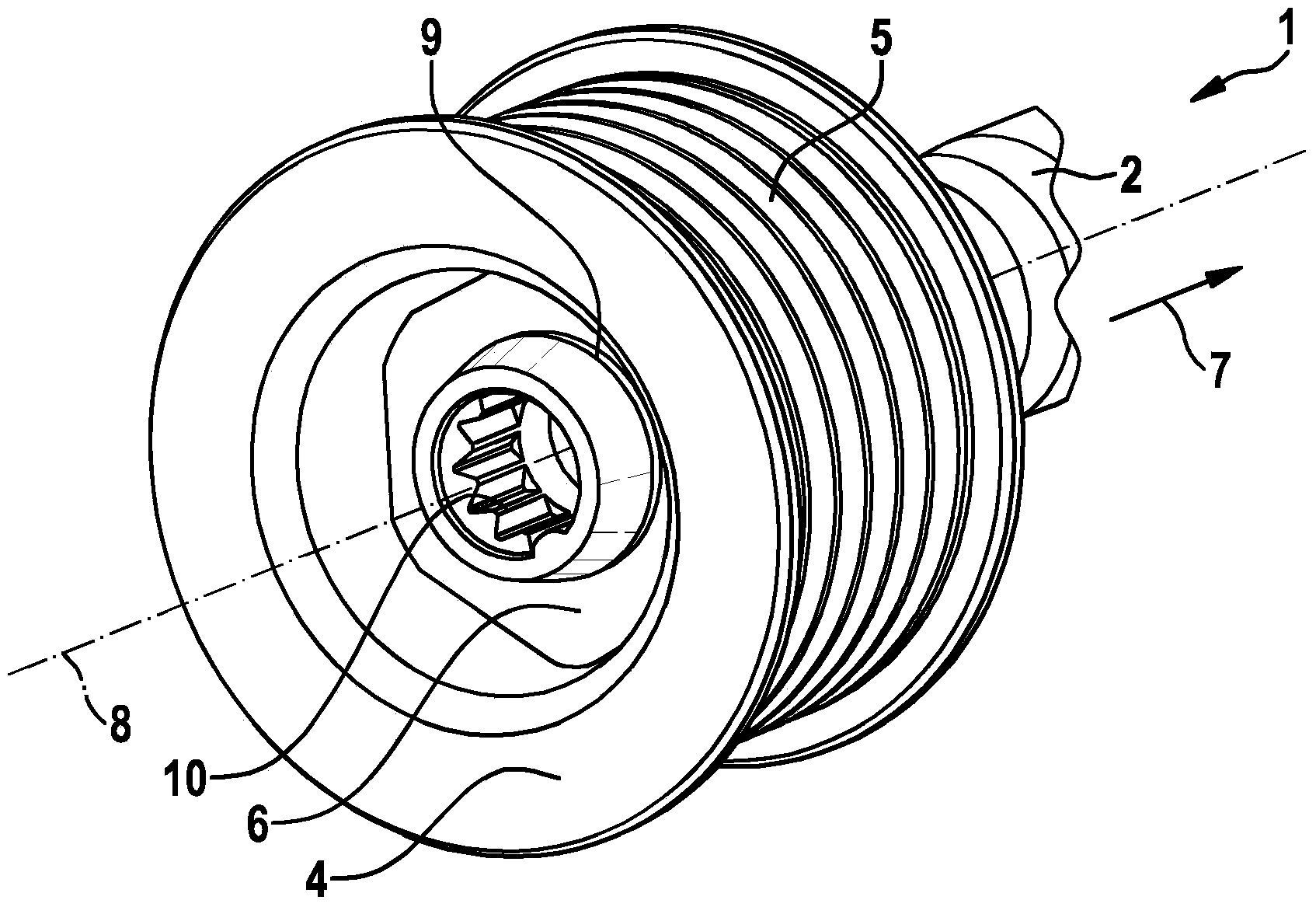

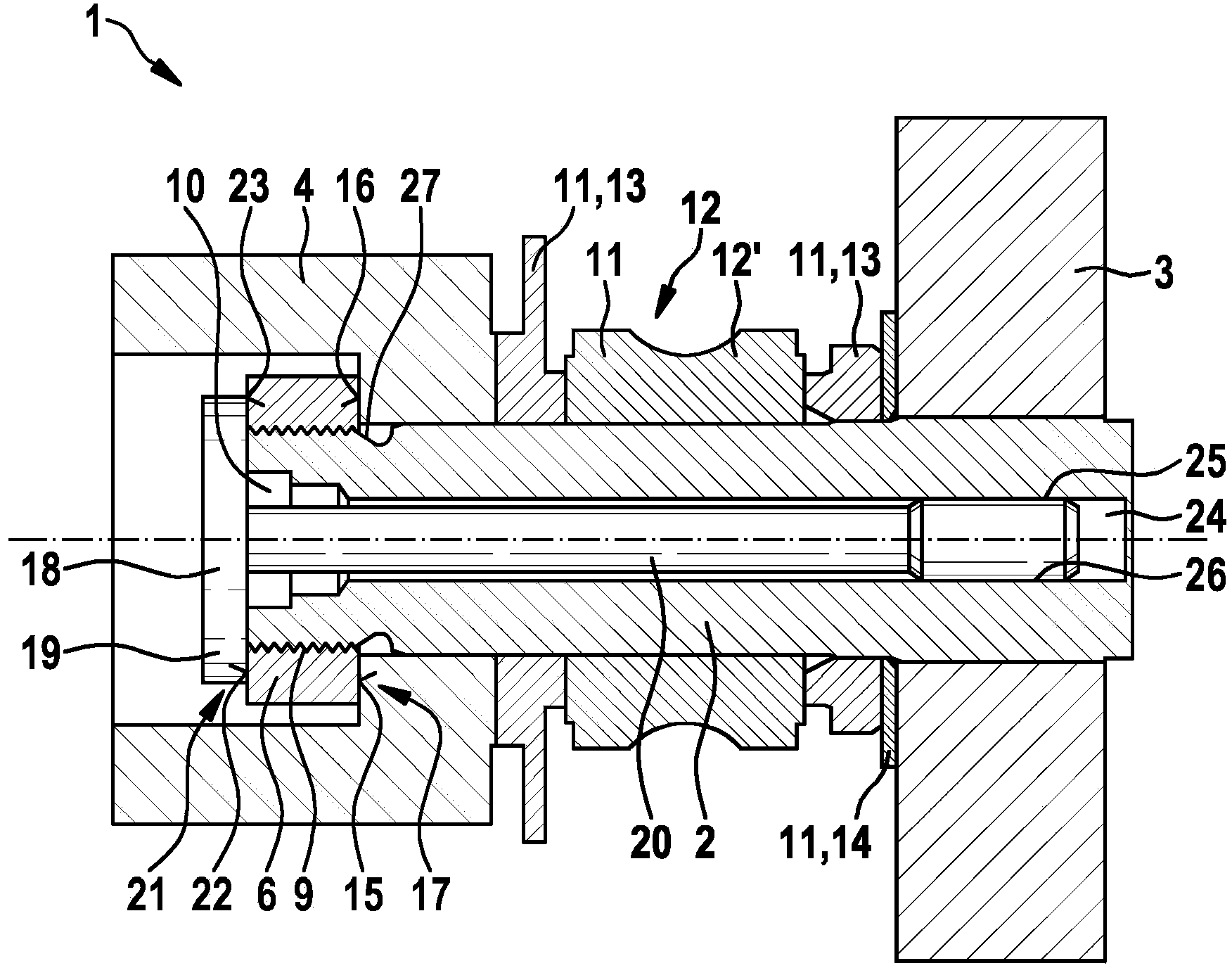

[0025] figure 1 A partial view of an electric machine 1 known from the prior art is shown. The electric machine 1 can be configured, for example, as an electric motor, generator or generator motor. It has a drive shaft 2 via which the electric motor can deliver or receive torque. A rotor 3 , not shown here, and a connecting element 4 , which is preferably axially spaced apart from the rotor 3 , are arranged on the drive shaft 2 . The connecting element 4 is configured, for example, as a belt pulley, ie has a running surface 5 for bending a loose encircling component, for example a running surface 5 for a belt. The connecting element 4 is fastened to the drive shaft 2 by means of a fastening element 6 and is pressed by the fastening element 6 in the direction of the rotor 3 , ie in the direction of the arrow 7 . The arrow 7 is here parallel to the longitudinal axis 8 of the drive shaft 2 and the electric motor 1 .

[0026] The fastening element 6 is designed as a nut, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com