Liquid-cooling type electronic-device radiator

An electronic device and cooling technology, which is applied in the direction of electric solid device, semiconductor device, cooling/ventilation/heating transformation, etc., can solve the problems of high cost and complex system, and achieve the effect of simple processing, compact device structure and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

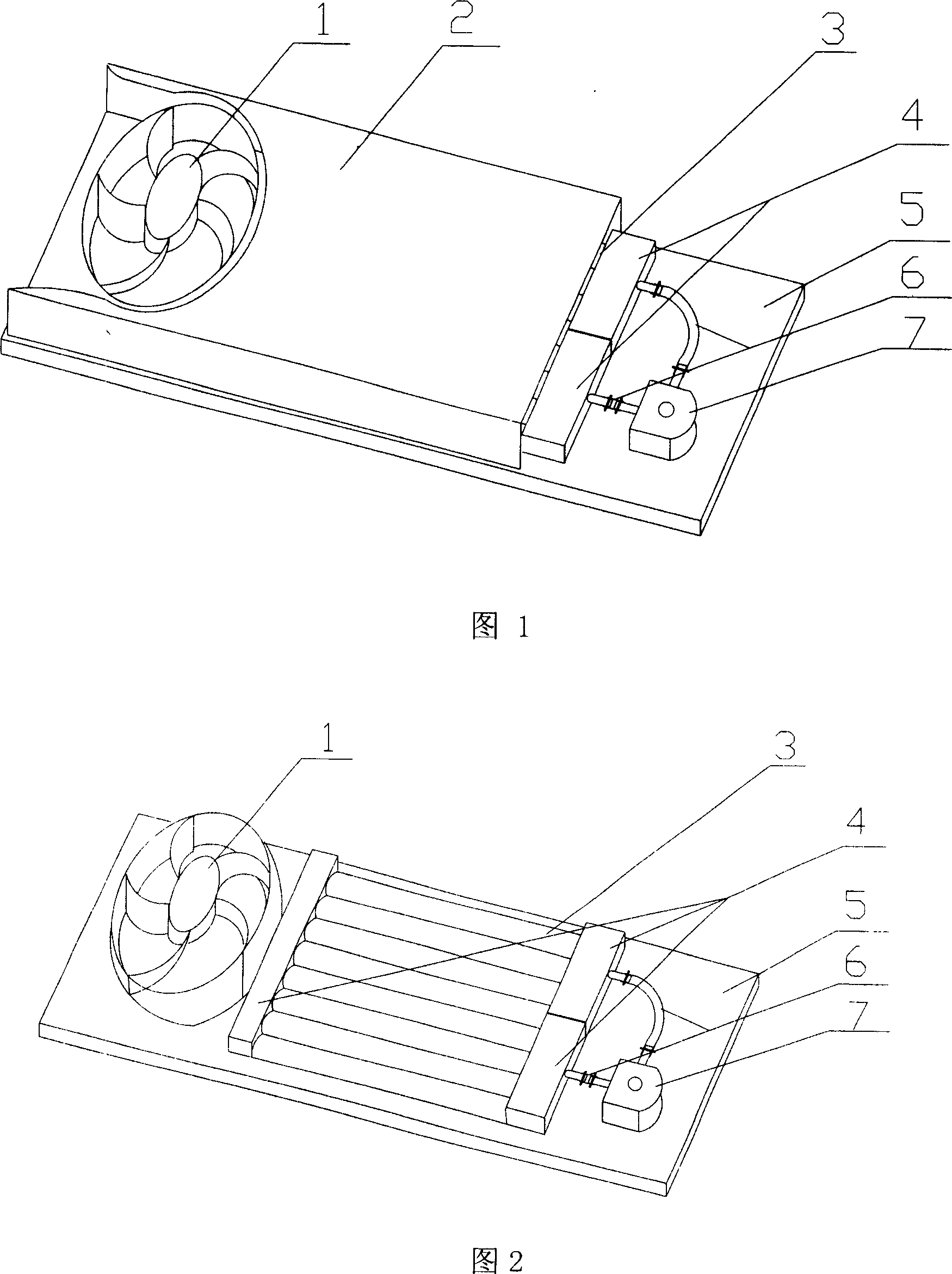

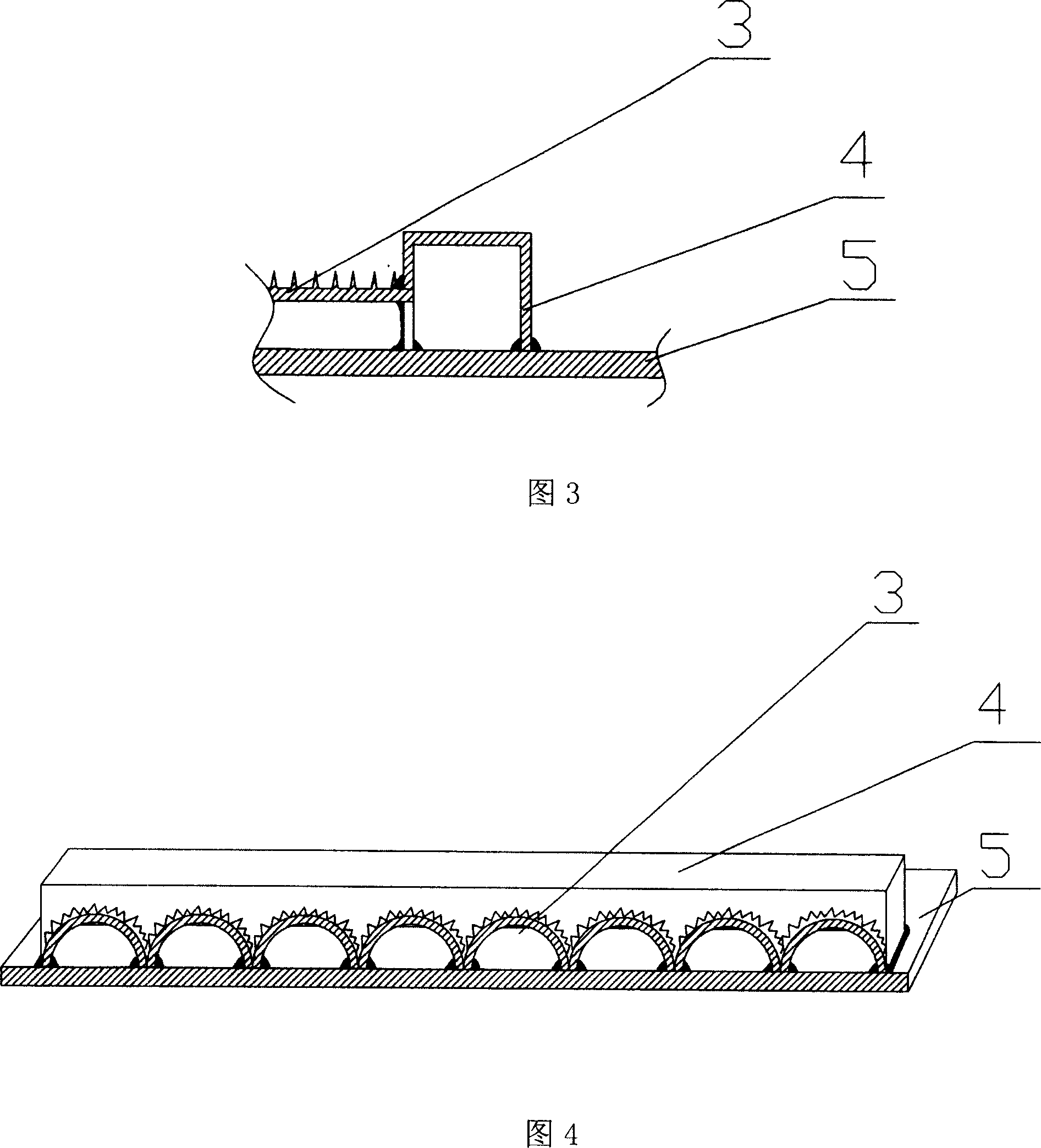

[0022] As shown in Figure 1, the main body of the liquid-cooled radiator includes a cooling fan 1, a cover plate 2, a high-efficiency heat sink 3, a connecting pipe box 4, a base plate 5, a hose 6, and a micro pipeline pump 7. The substrate 5 is made of a red copper plate with a thickness of 3-5 mm, which is rolled and formed according to the assembly requirements of electronic devices. As shown in Figure 2, the high-efficiency heat sink 3 is a semicircular or semi-elliptical copper tube cut in half, and eight high-efficiency heat sinks 3 are fixed on the substrate 5 in parallel, and the high-efficiency heat sink 3 has three-dimensional fins on the outside . The high-efficiency heat sink 3, the connecting pipe box 4 and the base plate 5 are fully welded. Purified water is used as the cooling liquid, driven by the micro pipeline pump 7 to circulate in the closed flow channel formed between the high-efficiency heat sink 3 and the base plate 5 . Electronic device chip heating p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap