Method and device for measuring and adjusting the evenness and/or tension of a special steel strip or special steel film in a multi-roll stand, particularly in a 20-roll sendzimir rolling machine

A straightness, special steel technology, applied in length measuring devices, chemical instruments and methods, cement mixing devices, etc., to eliminate mutual influence, save time, and reduce burdens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

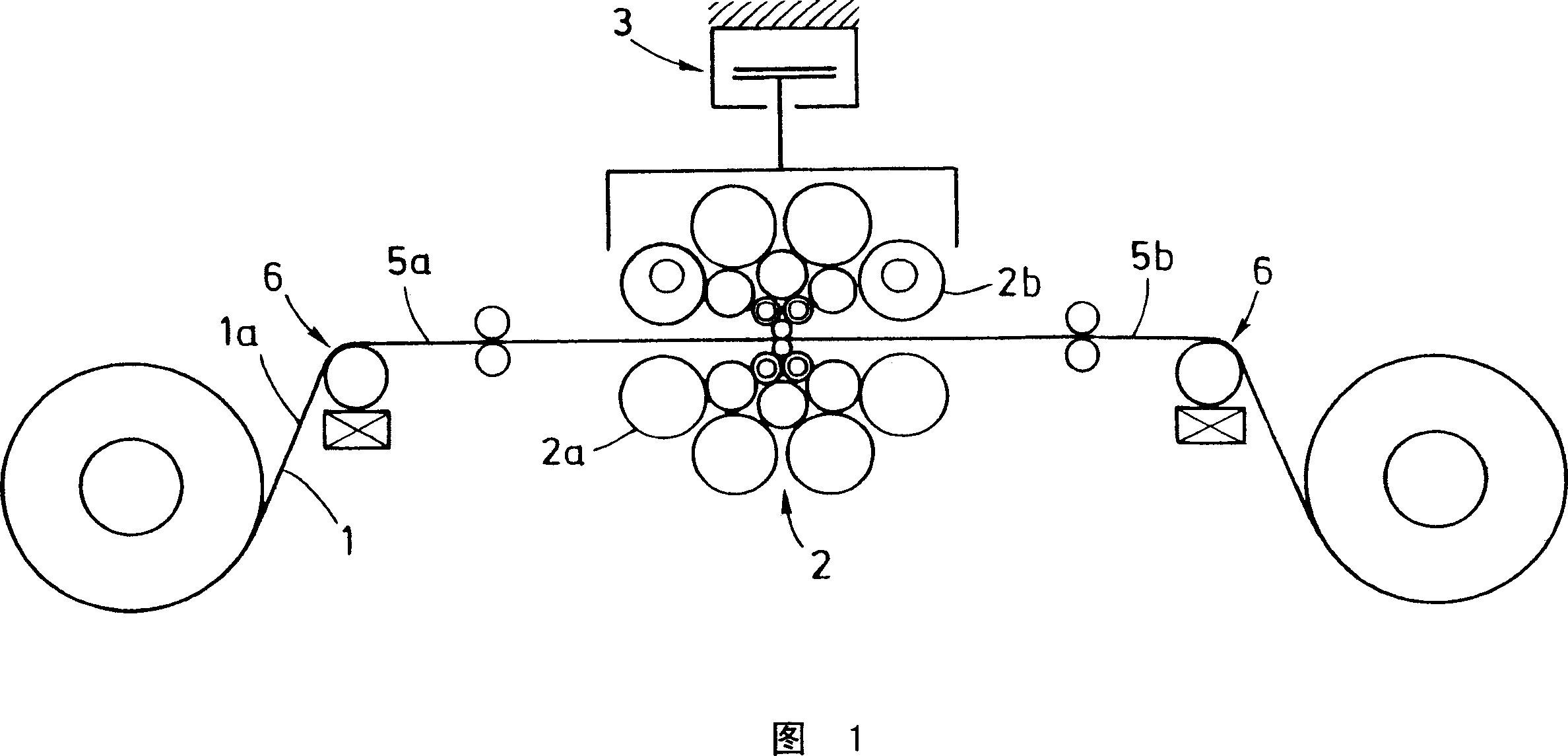

[0041] According to FIG. 1, a special steel strip 1 or a special steel foil 1a is rolled by rolling, rolling and coiling in a multi-roll stand 2 in a 20-high Sendzimir rolling mill 2a. In this case, the roll set 2b forms a split structure. The upper roller group 2b can be adjusted by an actuator 3 and other functions. The signal to be described is processed in a control loop 4 ( FIGS. 6-9 ). These signals come from the inlet 5a before the rolling process and from the outlet 5b after rolling and are obtained by means of flatness measuring elements 6 which in this embodiment consist of flatness measuring elements 6 Degree measuring roller 6a constitutes.

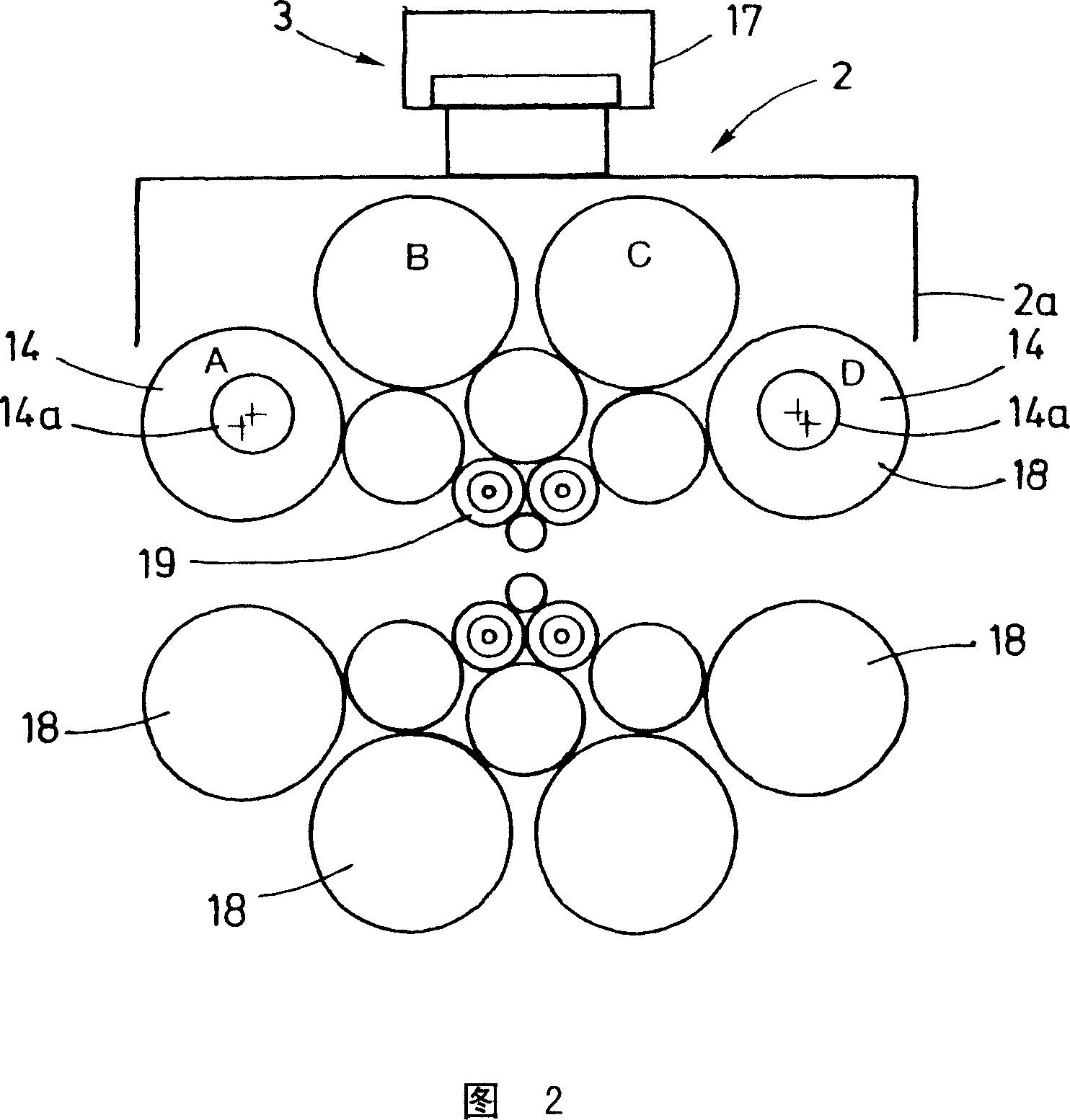

[0042] In FIG. 2, a hydraulic adjustment mechanism 17 is shown as an actuator for the upper roll set 2b. In order to affect the flatness of the strip, as the actuator 3, the hydraulic adjustment mechanism 17 can be rotated (only applied in the split structure form), the outer support rollers 18 (A, B, C, D, wherein the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com