Mixed storage water heater

A water heater and hybrid technology, applied in the field of hybrid storage water heaters, can solve the problems of unstable working process and low reliability, and achieve the effects of simple structure, reduced friction, and improved sensitivity and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

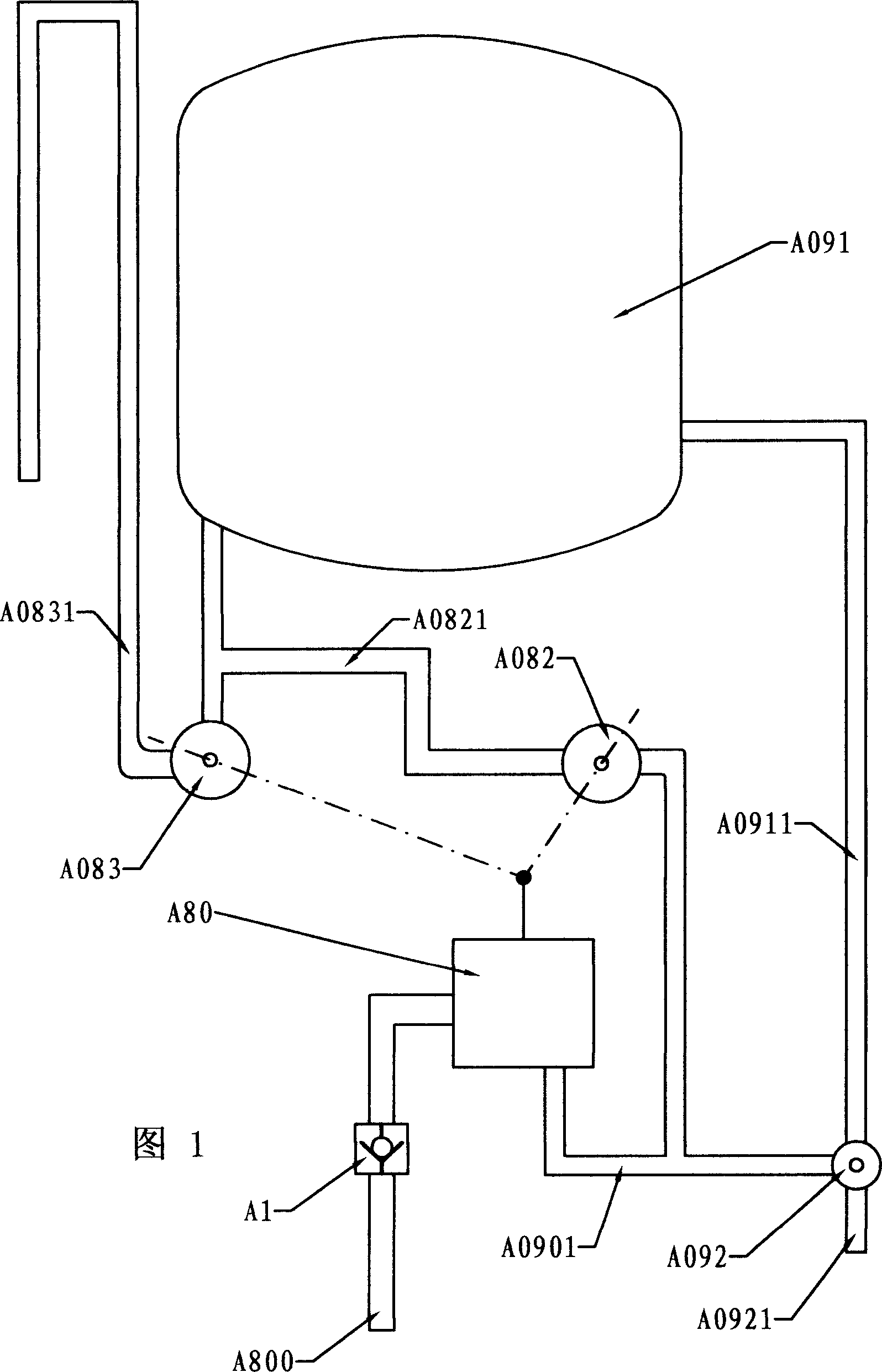

[0045] Embodiment 1, see Figure 1, the tap water pipe A800 is connected to the connection between the connection and the A0901 with a one-way valve three A1 and a water control expansion device A80, and the other end of the connection pipe A0901 is connected to the cold water inlet of the water mixing valve A092, and the water mixing valve The hot water pipe A0911 of the hot water inlet receiving the water tank, the cold water valve in the mixing valve A092 is equivalent to the water outlet valve, and the hot water valve is equivalent to the valve one, and the connecting pipe A0901 and the water supply pipe A0821 are connected to the valve two A082—— Its function is to control the cold water flowing to the water tank A091 through the connecting pipe A0901, which is equivalent to a water supply valve. There is a valve three A083 between the water tank A091 and the overflow pipe A0831, which is the overflow valve, and the valve three A083 and the valve two A082 are integrated in t...

Embodiment 2

[0051] Embodiment 2, as shown in Figure 8, the water heater includes a water tank 01, an electric heating pipe (located in the water tank—not shown in the figure), a hot water pipe 02, three water outlet valves 080, a tap water pipe 04 and a water supply pipe 03 , the tap water pipe 04 is connected to the water inlet 11 (see Figure 9) of the water control expansion device 05, and the tap water pipe 04 is provided with a check valve three (in the figure) that prevents the water in the water control expansion device 05 from flowing backward to the tap water pipe 04 Not shown), the water outlet 12 of the water control expansion device 05 (see Figure 9) is connected to the water supply pipe 03, the other end of the water supply pipe 03 is connected to the lower part of the water tank 01, and the water supply pipe 03 is also connected to a safety pressure relief valve 09, a one-way valve One end of two 07 is connected to the water supply pipe 03, the other end is connected to the co...

Embodiment 3

[0059] Embodiment 3, if an ordinary manual water mixing valve is used instead of an electric water mixing valve in the embodiment of FIG. 8 , the pipeline can be connected as shown in FIG. The outlet pipes of valve one 06 are directly connected to the hot water port of water mixing valve 991 after being connected, and the cold water port 992 of water mixing valve 991 is connected to the tap water pipe (or water supply pipe 03); The front valve two has been opened, so the water in the water-controlled expansion device can flow out through the water supply pipe, the water tank, the hot water pipe, the one-way valve one, the water mixing valve, and the water outlet to ensure the normal action of the plunger of the water-controlled expansion device.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap