Complex cable

A composite cable and cable tube technology, which is applied in the direction of insulated cables, communication cables, cables, etc., can solve the problems of large outer diameter and small flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

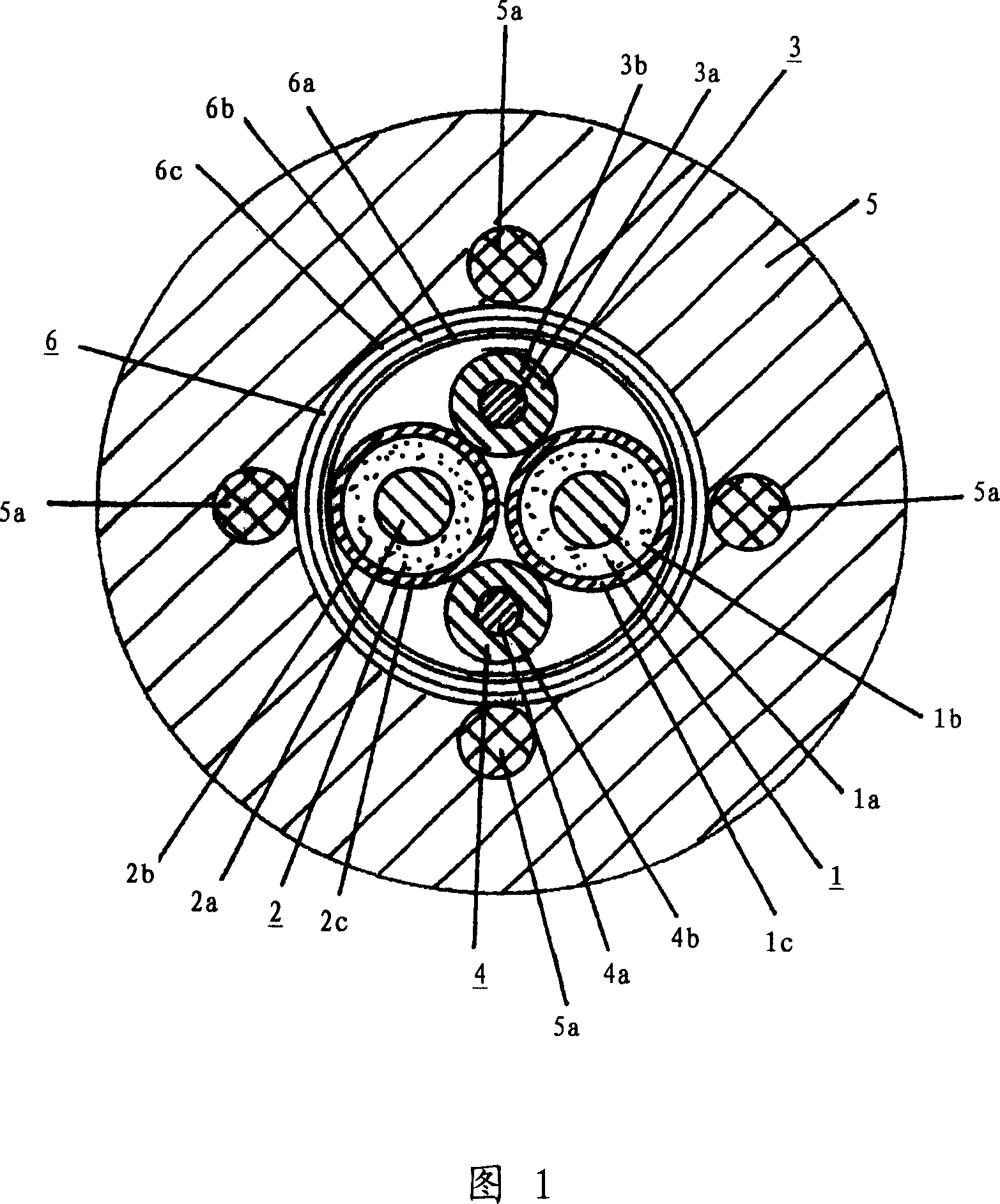

[0019] The composite cable consists of a pair of copper wires consisting of two insulated copper wires 1 and 2, two optical fibers 3 and 4, a sheath 5, and a cable core surrounded by the copper wire pair and the optical fibers 3 and 4. The coating consists of 6 layers.

[0020] The insulated copper wires 1 and 2 each consist of a conductor 1a, 2a which can be formed as a single copper wire or as a plurality of copper wires.

[0021] The copper wires 1a, 2a are surrounded by a first insulating layer 1b, 2b made of foamed polyethylene. A second insulating layer 1c, 2c of non-foamed polyethylene is arranged on the first insulating layer 1b, 2b. Such insulation structures are known per se in telecommunication cable technology and are referred to as foam sheaths. Insulated copper wires are twisted to each other and constitute the copper wire pairs.

[0022] The optical fibers 3 and 4 consist of glass fibers or plastic fibers 3a, 4a which, as is known, consist of an optical core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap