Connection structure of construction curtain wall cross beam and pillar

A technology for connecting structures and beams, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of multiple drilling, inconvenient adjustment deviation, poor torsional performance of corner codes, etc., to solve the unreasonable installation structure, solve The effect of inconvenient installation and enhanced torsional performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

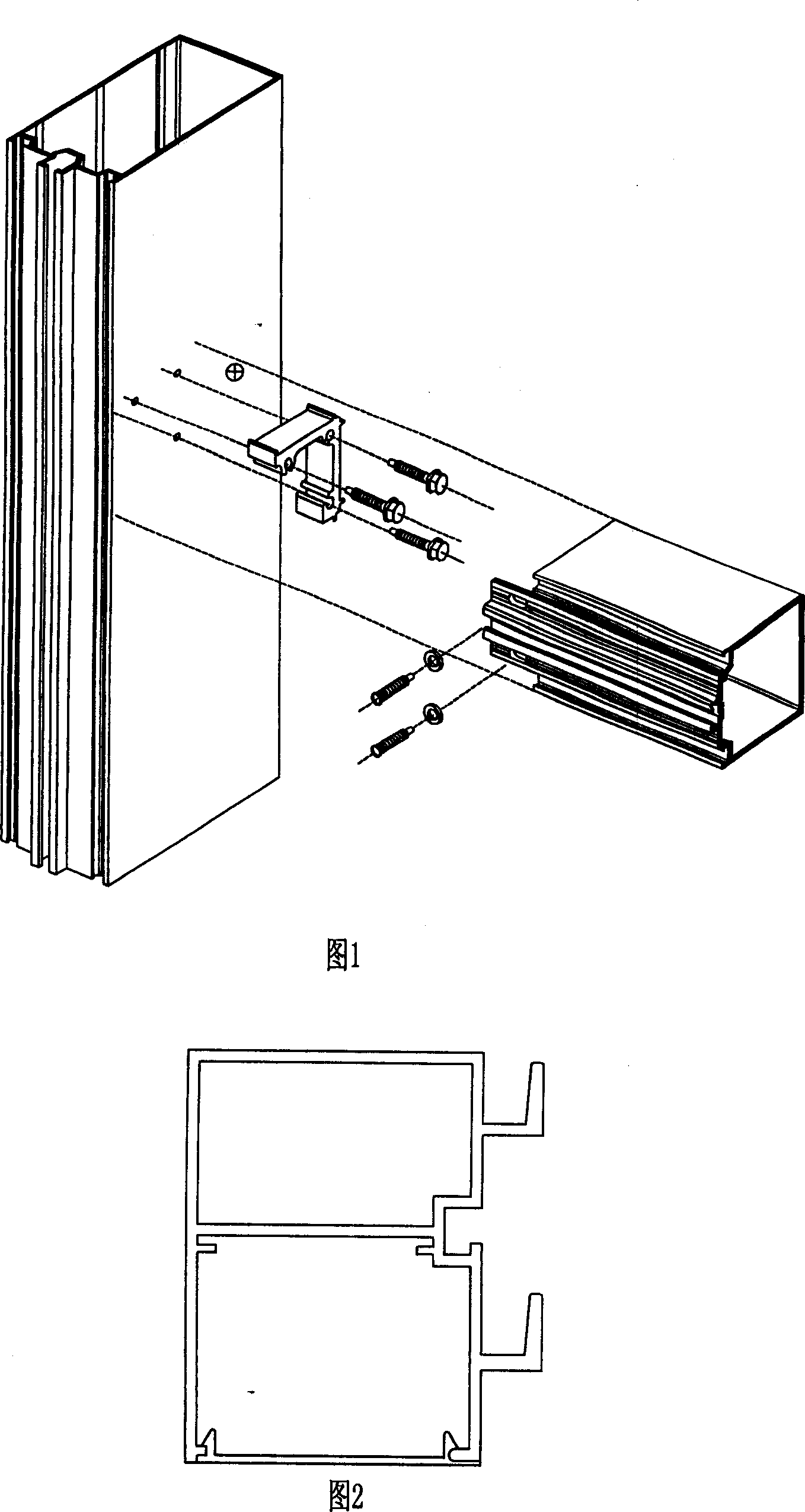

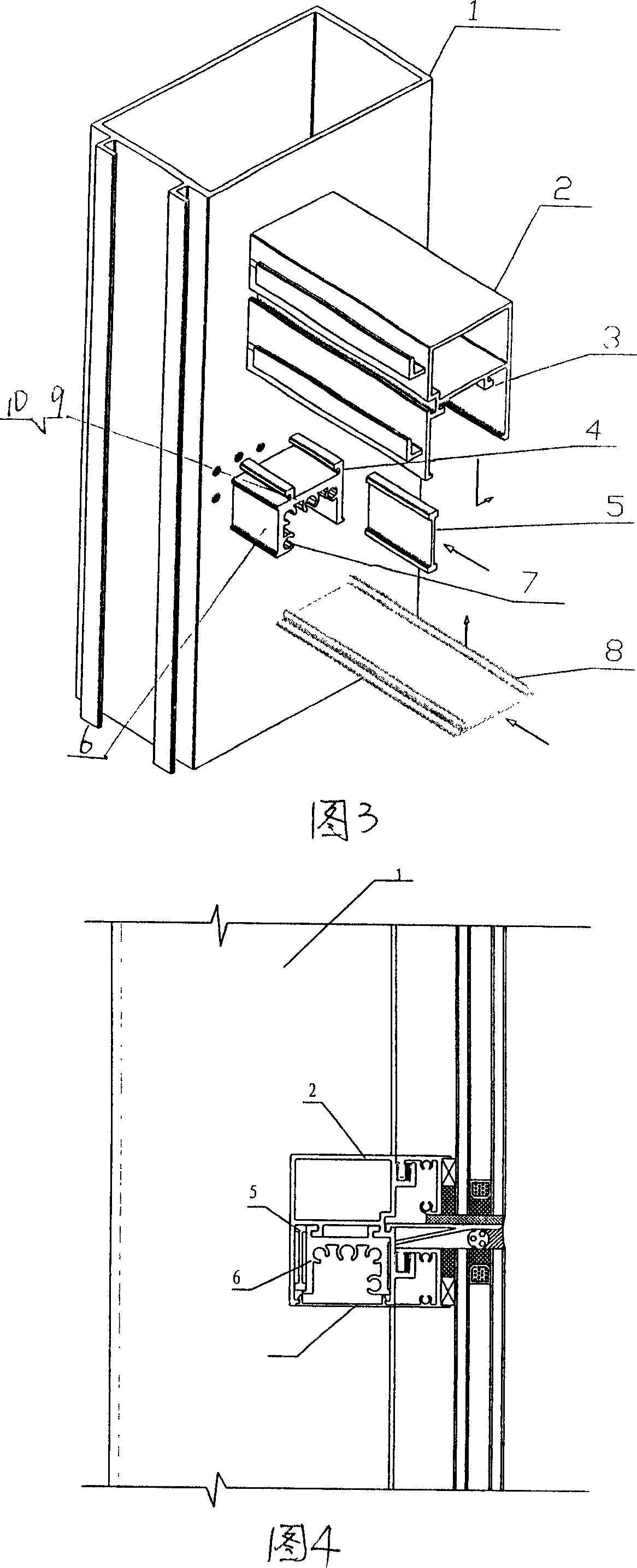

[0021] As shown in Fig. 3 and Fig. 4, in the connection structure of the building curtain wall beam and the column of the present invention, a connecting piece 6 is fixed on the column 1 by a screw 7, the connecting piece 6 is a door-shaped structure, and one side of the connecting piece 6 is There are two notches 4 in the same direction on the top surface, and there can be more than two notches 4. In the inner cavity of the beam 2, there are reverse inner grooves that are opposite to the notches 4 of the connector 6 and can be interlocked. port 3, and the connecting piece 6 is connected together through the interlocking of the notches 3 and 4; the other side of the connecting piece is provided with a positioning fastening device at the interval between the inner cavity side wall of the beam; the positioning fastening device adopts a connecting The other side of the part 6, that is, the side foot, is provided with a boss 11, and a clamping part 5 is arranged on the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com